Light-emitting diode and fabricating method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied to electrical components, circuits, semiconductor devices, etc., and can solve problems such as difficulty in achieving long-distance lighting, increased lighting costs, and poor directivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiments with reference to the accompanying drawings.

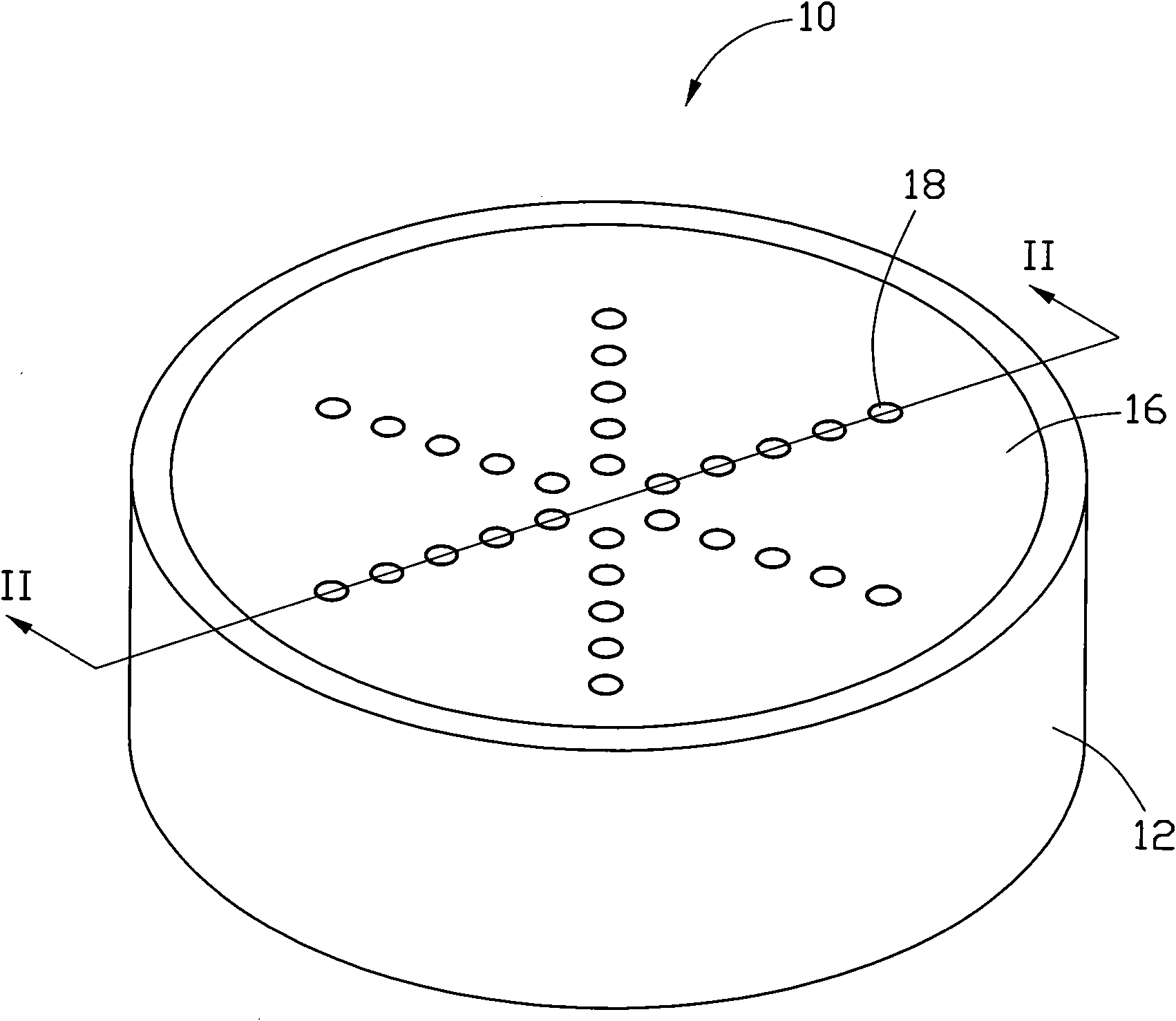

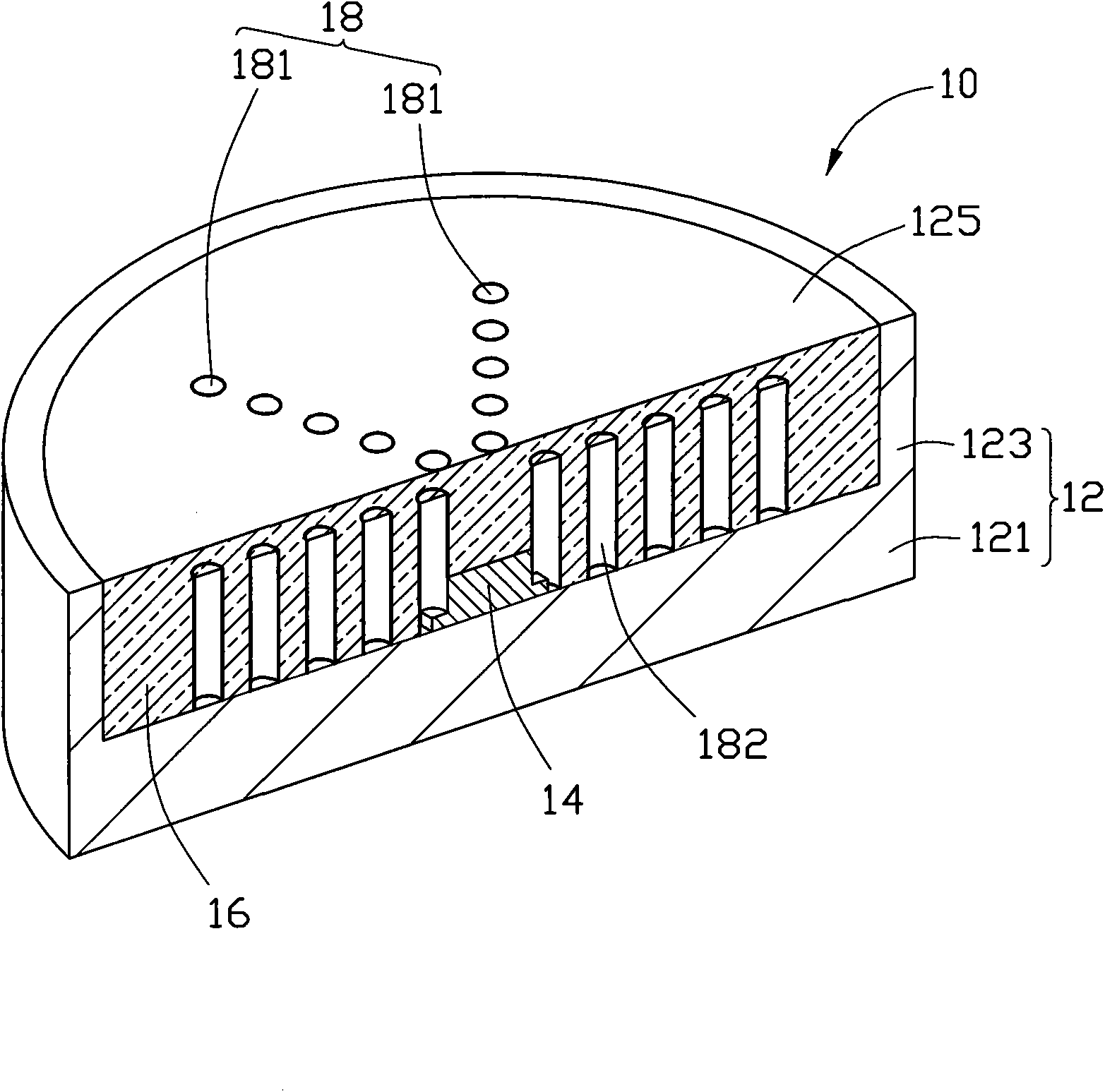

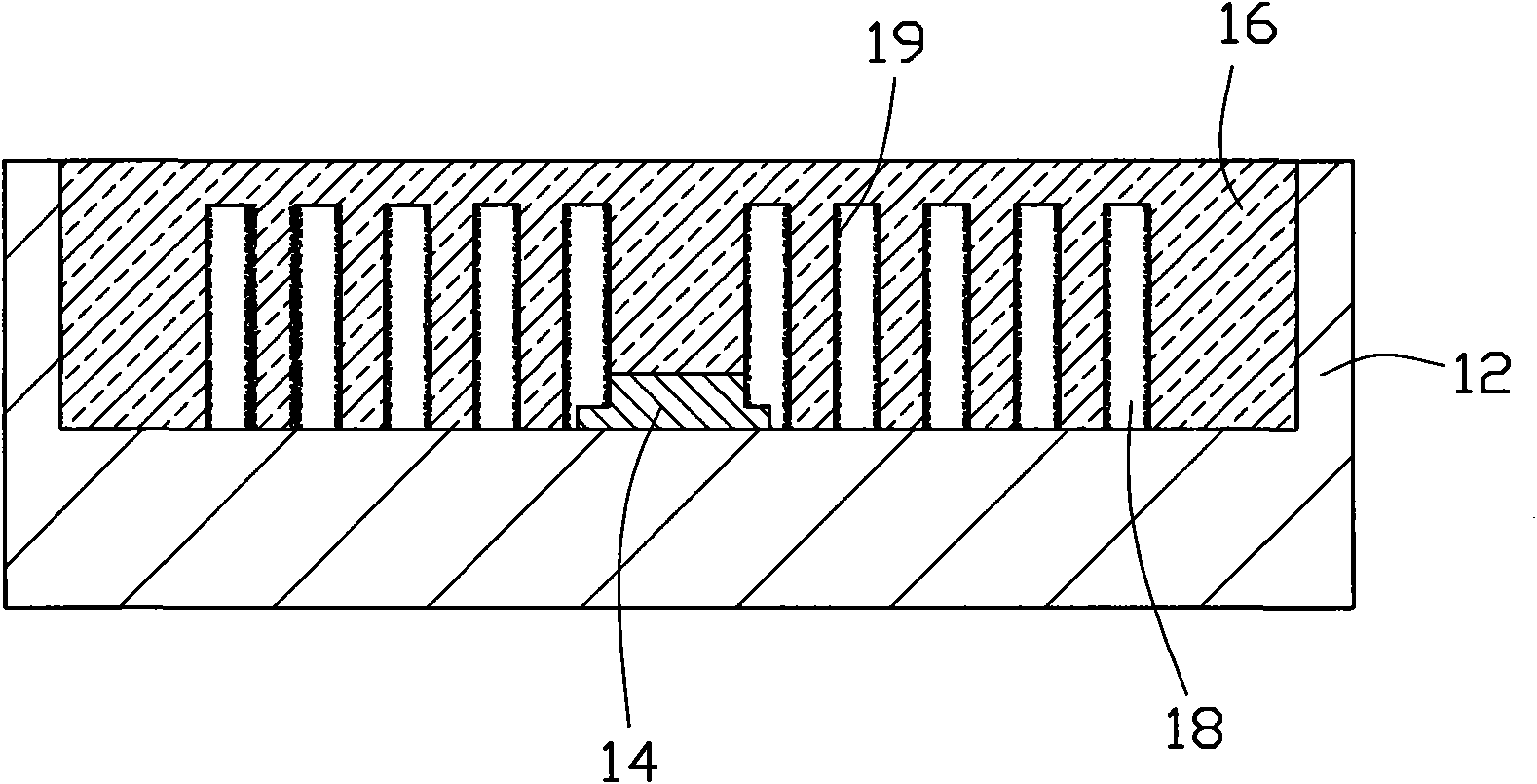

[0014] see figure 1 and figure 2 , the light emitting diode 10 of the present invention includes a base 12 , a light emitting chip 14 and a glue 16 .

[0015] The base 12 is made of conductive and thermally conductive metal and other materials, and includes a base plate 121 and a bowl cup 123 located above the base plate 121 . The substrate 121 is connected to an external power supply through pins. The bowl cup 123 is integrally formed with the base plate 121 , and forms a receiving cavity with the base plate 121 . The inner surface of the bowl cup 123 is a highly reflective surface to reflect the light incident on the sidewall of the bowl cup 123 to the light exit surface 125 located at the opening of the bowl cup 123 . In order to make the inner surface of the bowl 123 form a highly reflective surface, reflective layers such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com