Method for improving optical power stability of semiconductor laser

A laser and stability technology, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problem that the solder cannot be deformed, and achieve the effects of stable optical power, improved stability, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

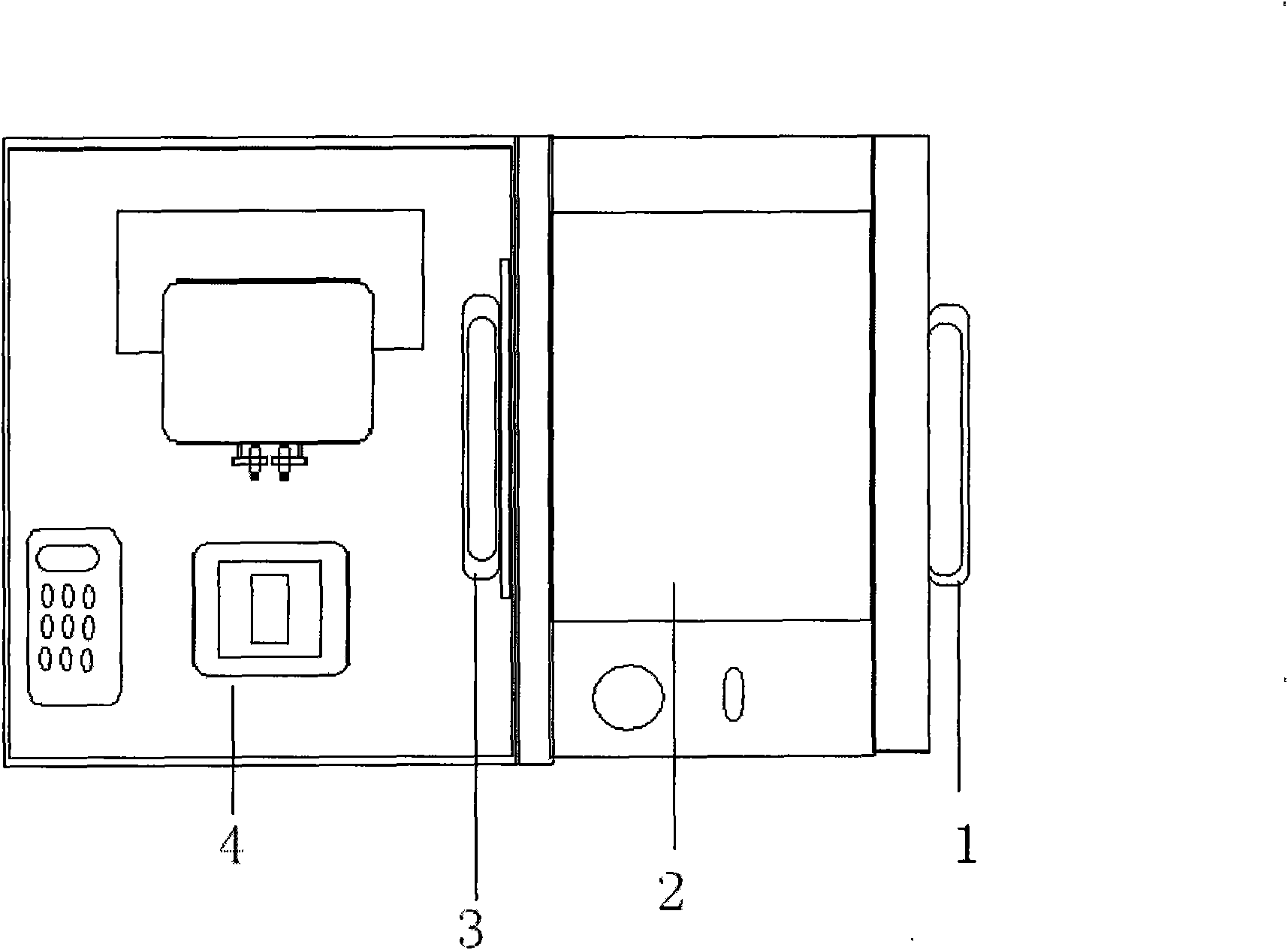

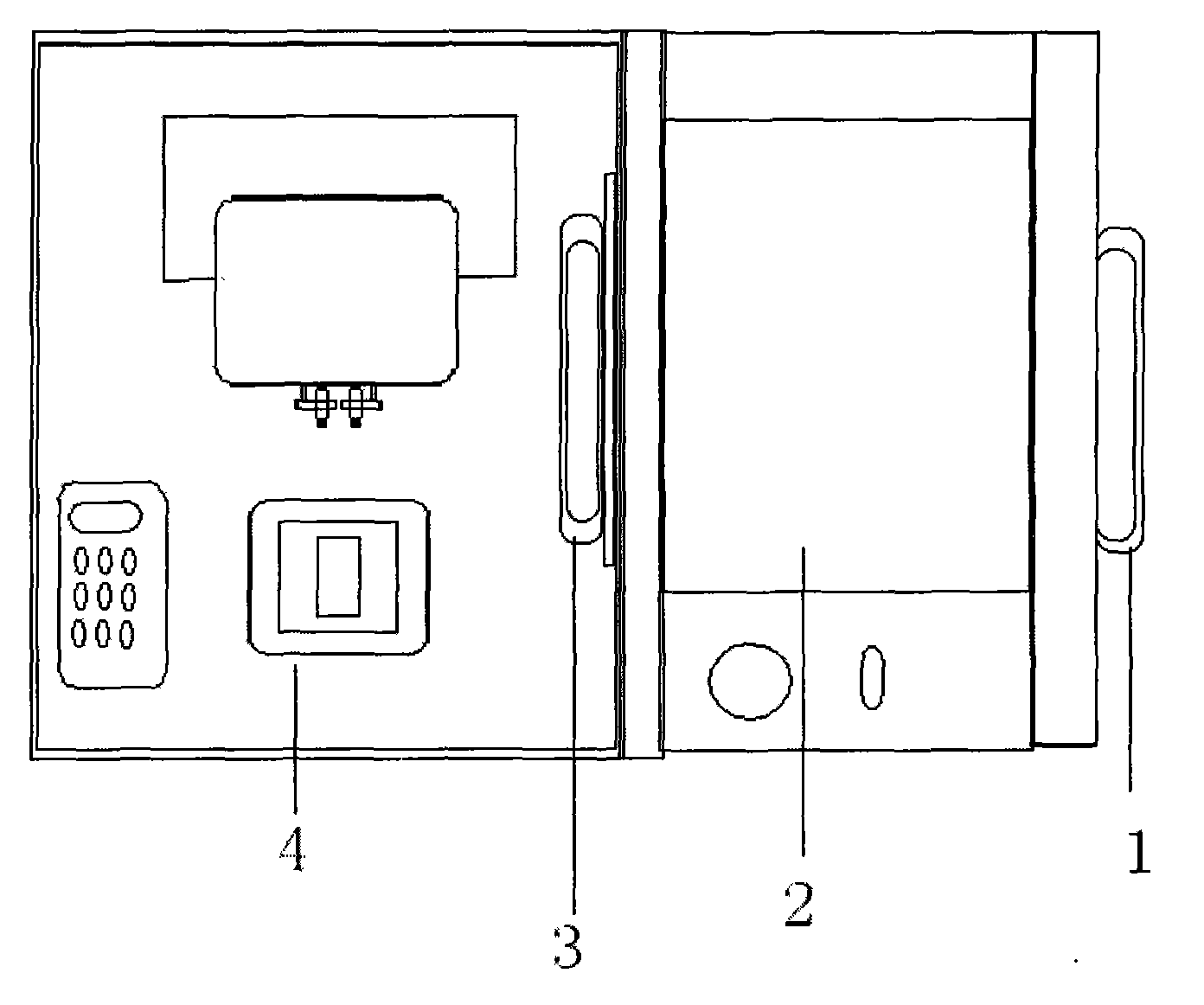

[0017] Method of the present invention can be realized on conventional capping machine, and the concrete steps of its embodiment are as follows:

[0018] ① Open the inlet and outlet door 1 of the capping machine and put the laser component into the vacuum oven 2 that comes with the capping machine;

[0019] ②Close the inlet and outlet door 1 of the capping machine;

[0020] ③ Vacuumize the vacuum oven 2 until the air pressure in the oven is 0.5 mm Hg;

[0021] ④ Fill dry nitrogen into the vacuum oven 2 that has been evacuated until the air pressure in the oven is 760 mm Hg;

[0022] ⑤ Vacuumize the vacuum oven 2 until the air pressure in the oven is 0.5 mm Hg;

[0023] ⑥ Fill the vacuum oven 2 with dry nitrogen until the air pressure in the oven is 760 mm Hg;

[0024] ⑦ Turn on the heating switch of the vacuum oven 2, set the heating temperature to 105 degrees Celsius, and the heating time to 16 hours;

[0025] 8. While performing step 7., maintain the air pressure in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com