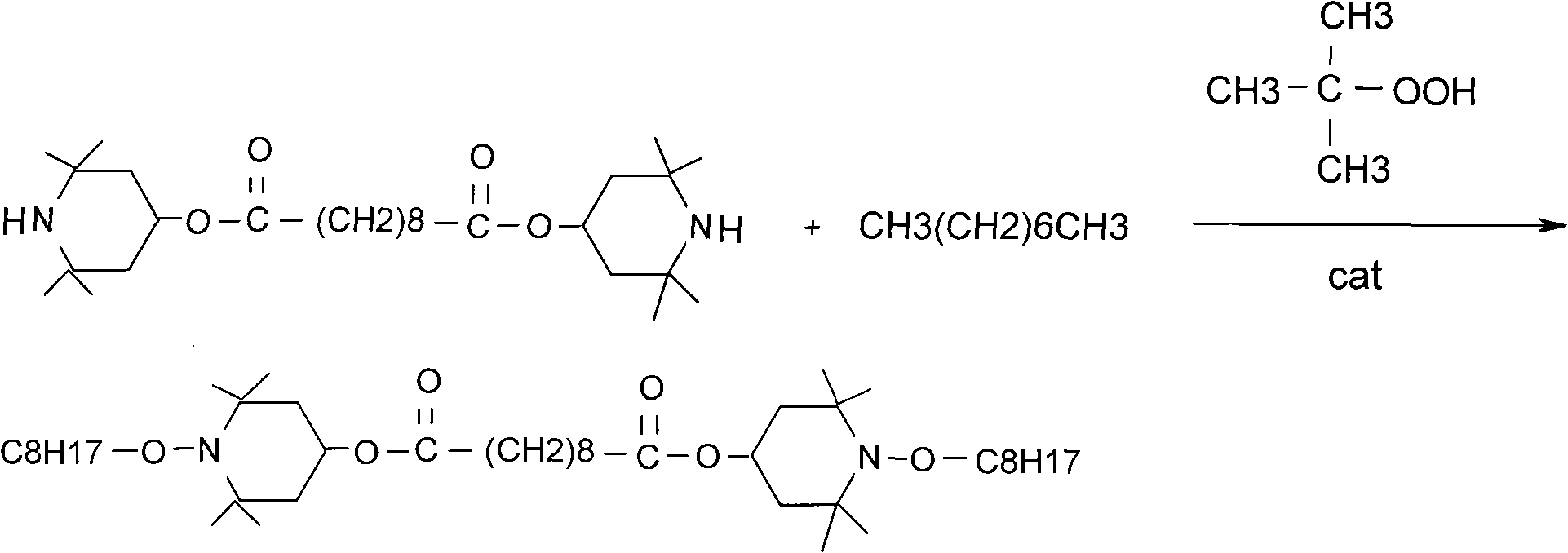

Process for preparing bi-(n-octyloxy-2,2,6,6-tetramethyl-piperidyl) diester sebacate

A technology of tetramethylpiperidyl and tetramethylpiperidine is applied in the preparation field of hindered amine light stabilizers, and can solve the problems of limited application scope, poor anti-risk ability, small scale and the like, and achieves simple reaction process and high product quality. Good color and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

[0012] example 1

[0013] In a four-necked flask equipped with a reflux condenser and a water separator, 76 g of bis(2,2,6,6-tetramethylpiperidine) sebacate and 450 ml of n-octane were added, and a small amount of catalyst was added and stirred The temperature is raised to 115°C, 140 grams of 70% tert-butyl hydroperoxide is added dropwise, after 6 hours, the water is continuously separated by the water separator. After dripping and refluxing for 5 hours, cool and filter, filter off the catalyst, add 10 grams of activated carbon to the filtrate and stir at room temperature for 30 minutes, then filter, the mother liquor is distilled under reduced pressure, and the n-octane is evaporated to obtain 93 grams of light yellow finished product, the yield is 80% .

Example

[0014] Example 2

[0015] In a four-necked flask equipped with a reflux condenser and a water separator, 76 g of bis(2,2,6,6-tetramethylpiperidine) sebacate and 450 ml of n-octane were added, and a small amount of catalyst was added and stirred The temperature is raised to 115°C, and 100 grams of 70% tert-butyl hydroperoxide is added dropwise. After 6 hours, the water is continuously separated by the water separator. After dripping and refluxing for 5 hours, cool and filter, filter out the catalyst, add 10 grams of activated carbon to the filtrate and stir at room temperature for 30 minutes, then filter, the mother liquor is distilled under reduced pressure, and the n-octane is evaporated to obtain 87 grams of red-brown finished product. The yield is 75%. .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap