Finger joint stock lumber for construction and manufacturing method thereof

A technology for specifications and structures, which is applied in the manufacture of tools, truss structures, and finger joints. , Improve the stability of mechanical properties and reduce the effect of variability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Cut the non-standard-length plantation fir gauge timber (obtained by sawing logs with a breast diameter of 20-35cm) into gauge timber with a fixed length of 0.5-1m as the finger-joint unit, and the moisture content of the finger-joint unit should be controlled at 10%-15% %, the cross-sectional size is 45mm×90mm, and there are no defects such as knots, cracks, etc. within 5cm from the finger-joint end of the standard timber.

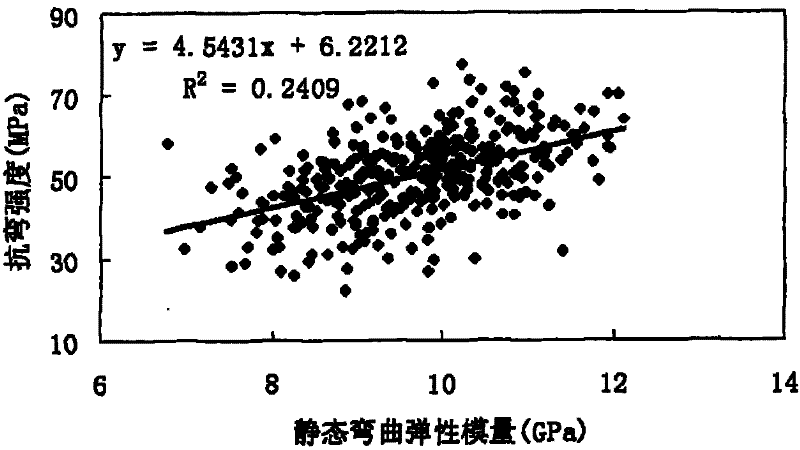

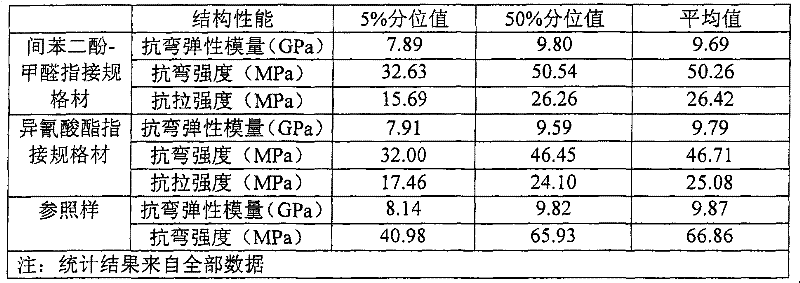

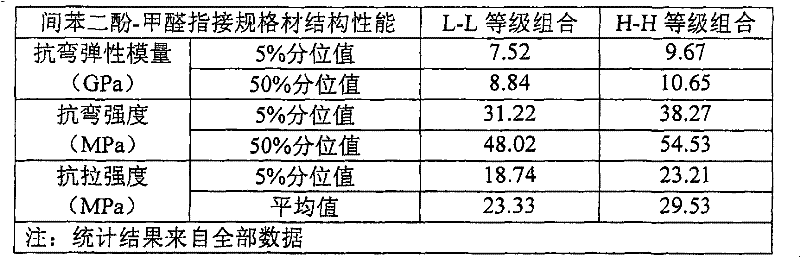

[0045] According to this embodiment, the fir finger-jointed material for plantation is finally used for wall studs, and the target grades are determined to be 8.5 GPa (L grade) and 11 GPa (H grade). In this embodiment, 0.88 is selected as the multiple for plantation fir, and the elastic modulus range of the H grade is determined to be above 9.7 GPa, and the elastic modulus range of the L grade is below 9.7 GPa and above 7.5 GPa.

[0046] Hang the two ends of the finger joint unit on the elastic rubber band, and the fulcrum position is located withi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com