Module connected combined type energy conservation and heat preservation moulding board for wall body construction

A technology of thermal insulation wall and module connection, applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connector, and on-site preparation of building components, etc. Wall decoration materials construction requirements and other issues, to achieve the effect of fast construction, low cost, accurate wall section size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

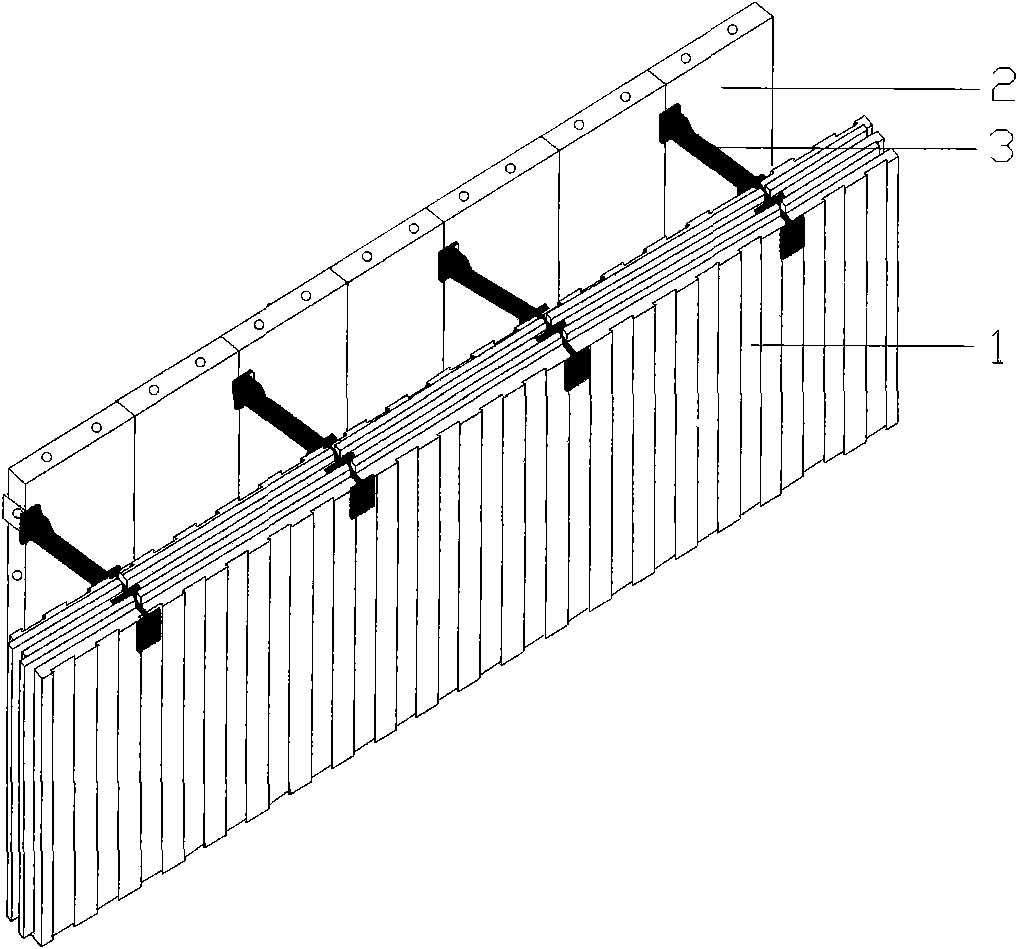

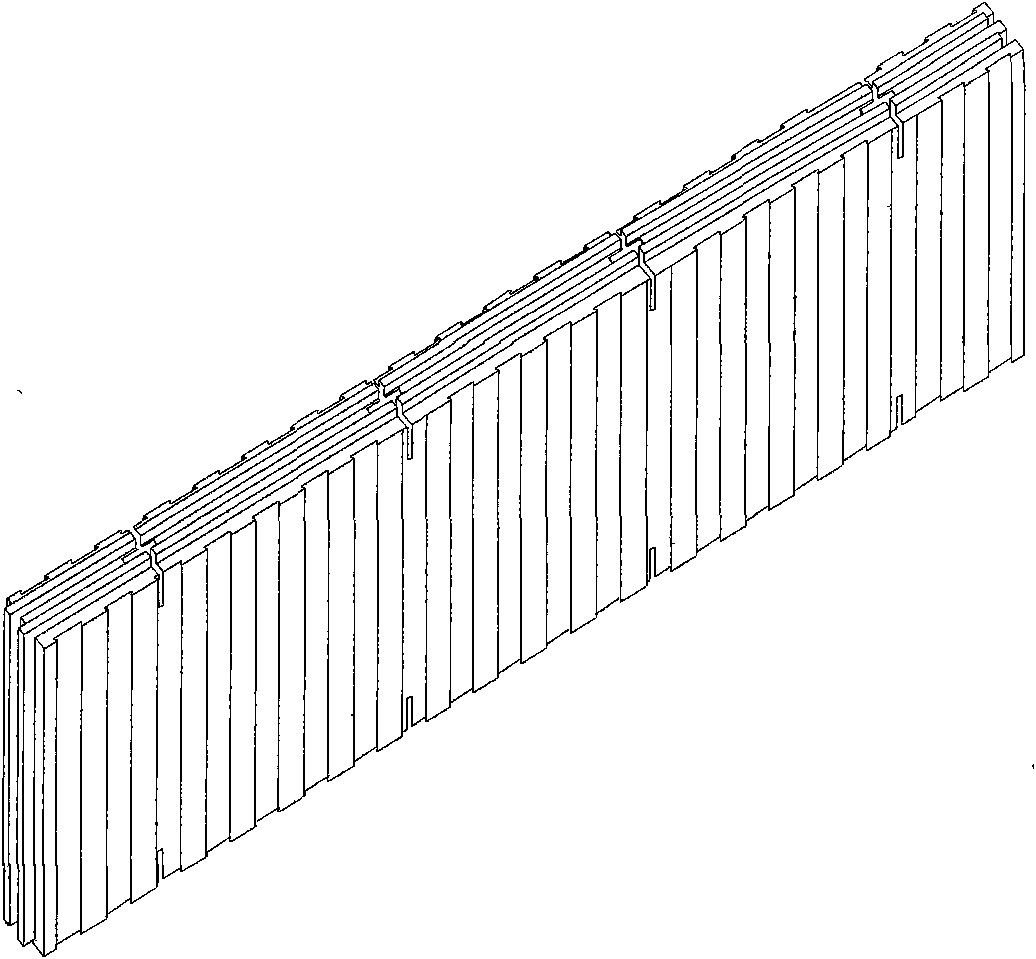

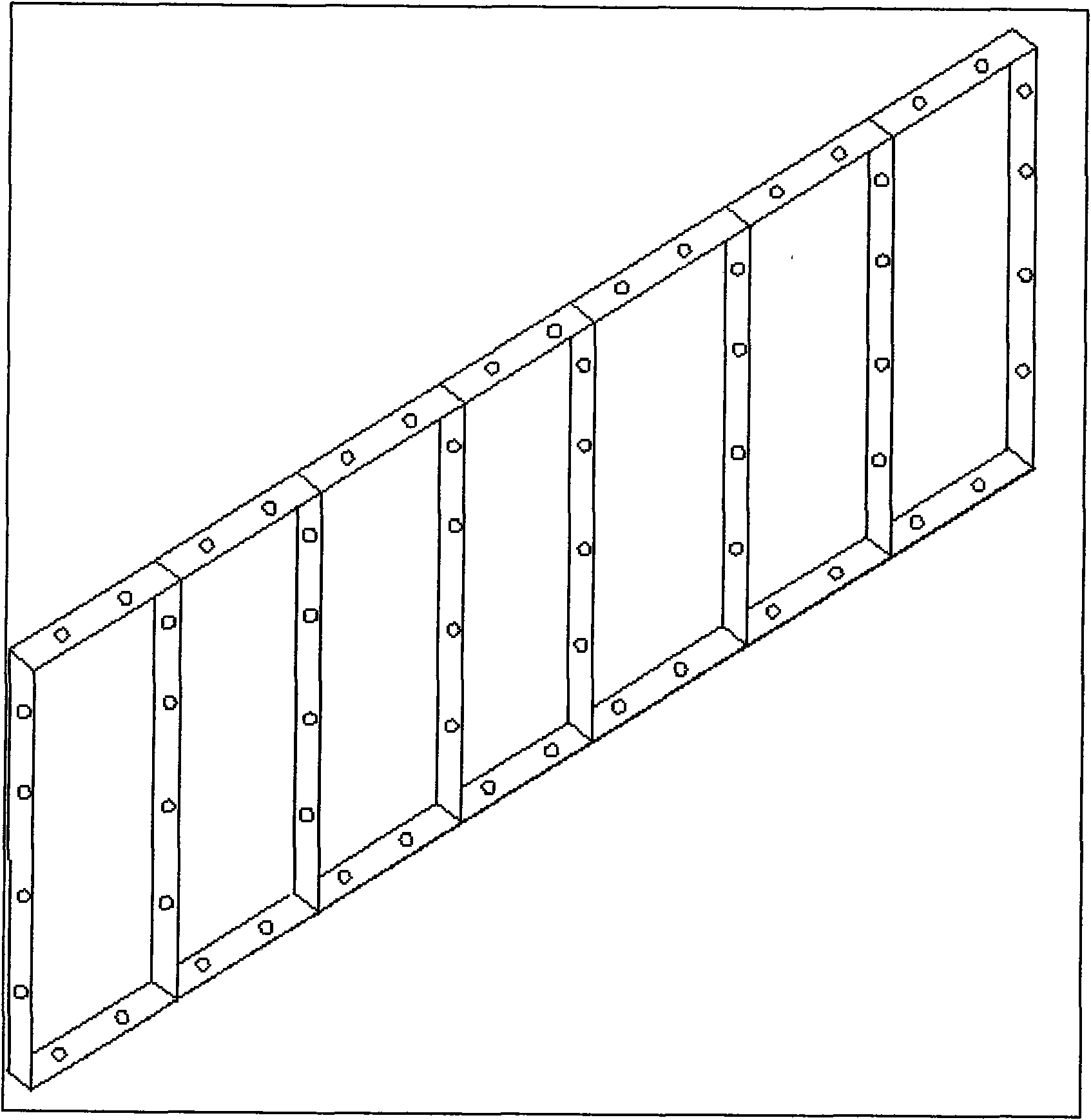

[0022] combine figure 1 , The composition of the modular connection combined energy-saving and thermal insulation wall construction formwork of the present invention includes an outer formwork 1, an inner formwork 2 and a connector 3 connected between the inner and outer formworks. The outer formwork is composed of energy-saving and thermal insulation modules plugged together. The connector is composed of a connecting plate 10 and connecting heads which are located at two ends of the connecting plate and respectively match with the inner and outer formworks.

[0023] combine Figure 4 and Figure 5 , the connecting head matched with the outer formwork is composed of a protruding end plate 4 and a clamping plate 5, the distance between the end plate and the clamping plate is equal to the thickness of the energy-saving heat preservation module, and the end plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com