Brake device

A technology of braking device and transmission system, applied in the direction of braking action starting device, automatic starting device, brake, etc., can solve the problem of not being particularly durable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

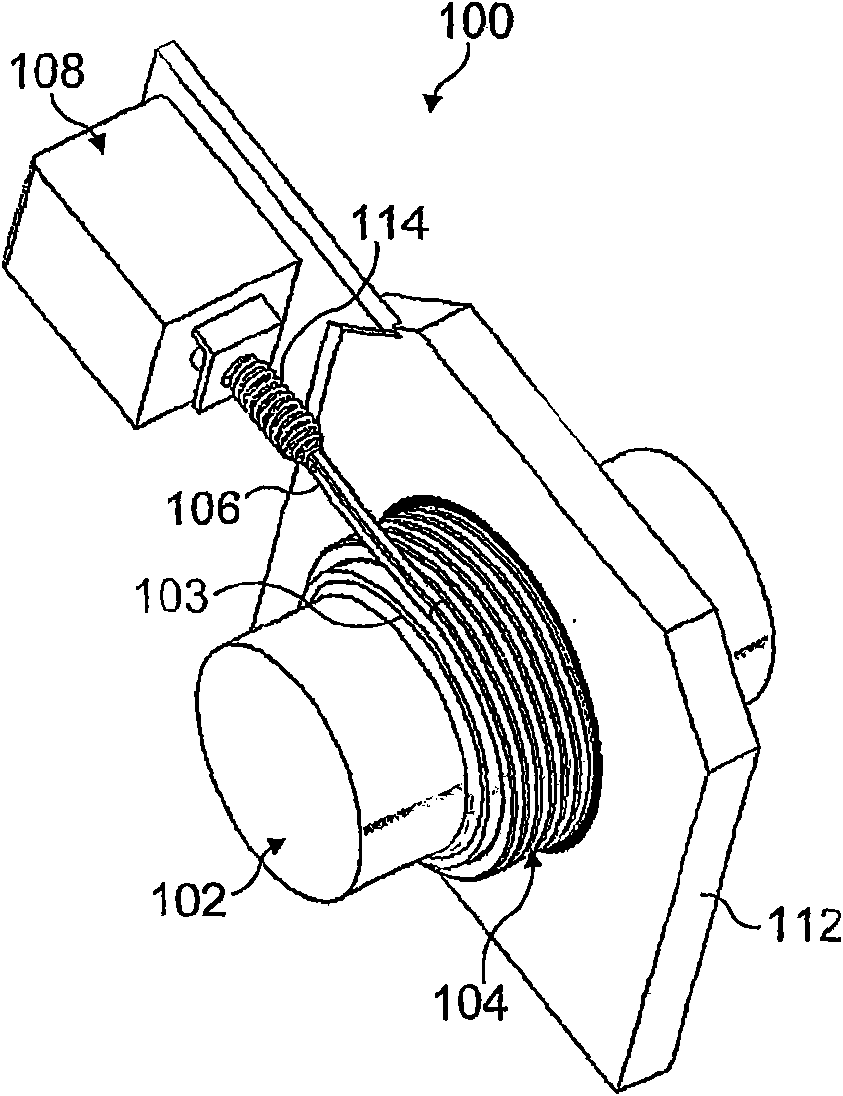

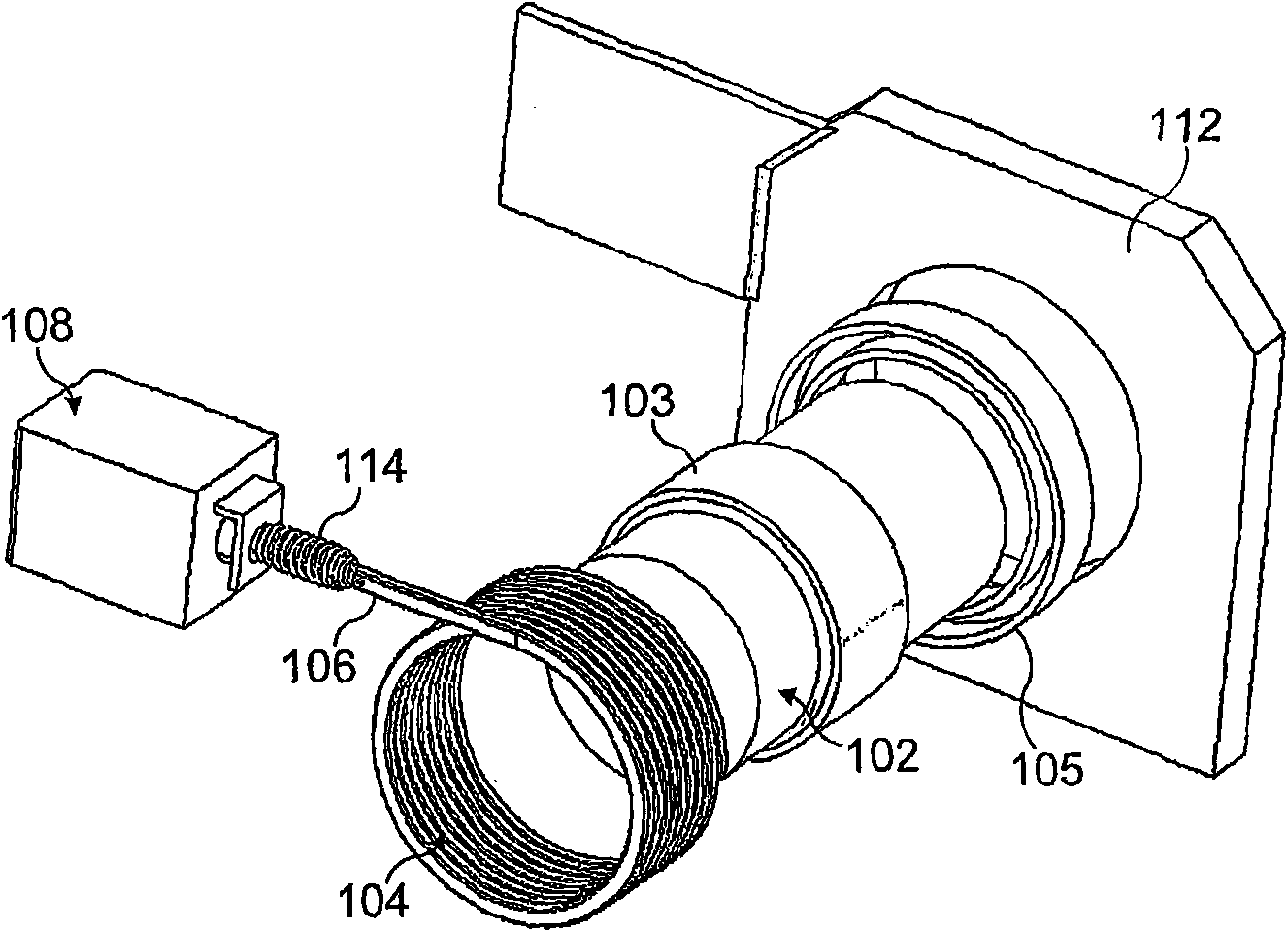

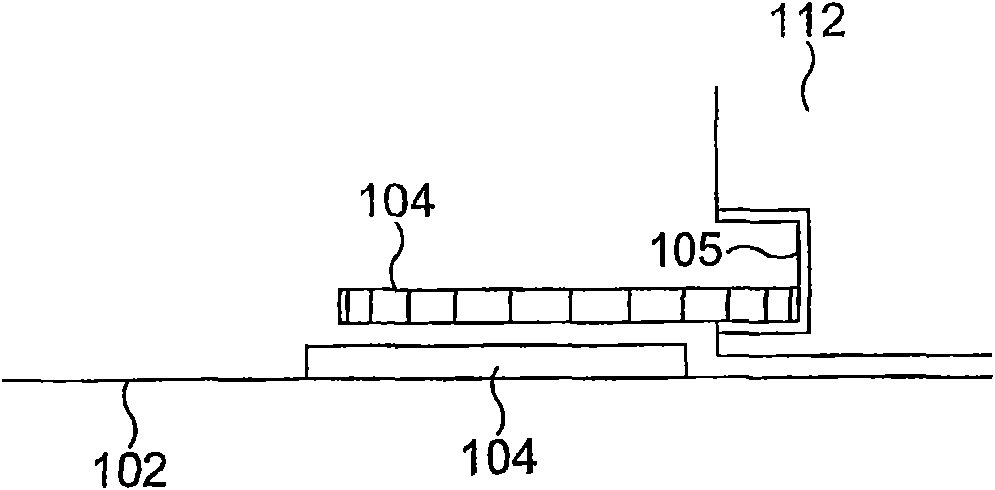

[0033] First refer to figure 1 and figure 2 , the braking device is generally indicated at 100 and includes a coil spring / torsion spring 104 mounted around an enlarged diameter portion 103 of a shaft 102 . The coil spring 104 has a coiled structure with a known relaxed diameter that is larger than the diameter of the enlarged diameter portion 103 so that under normal operating conditions there is a gap between the coil spring and the shaft 102 .

[0034] The inner end of the coil spring 104 is firmly anchored to the ring 105 or other anchor point separate from the shaft 102 . In this embodiment, ring 105 is formed on a portion of gearbox 112 (see figure 2 ).

[0035] In use, the solenoid 108 may be electrically controlled to tension the free end 106 of the coil spring 104 thereby tensioning the coil spring 104 around the shaft 102 . Once the control device 108 is energized, the action of the coil spring 104 is sufficient to retard or prevent rotation of the shaft 102 due...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com