Apparatus for conveying containers with non circular cross section

A non-circular cross-section, container technology, applied in the field of container devices, can solve the problem of a lot of rotating guides sticking out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

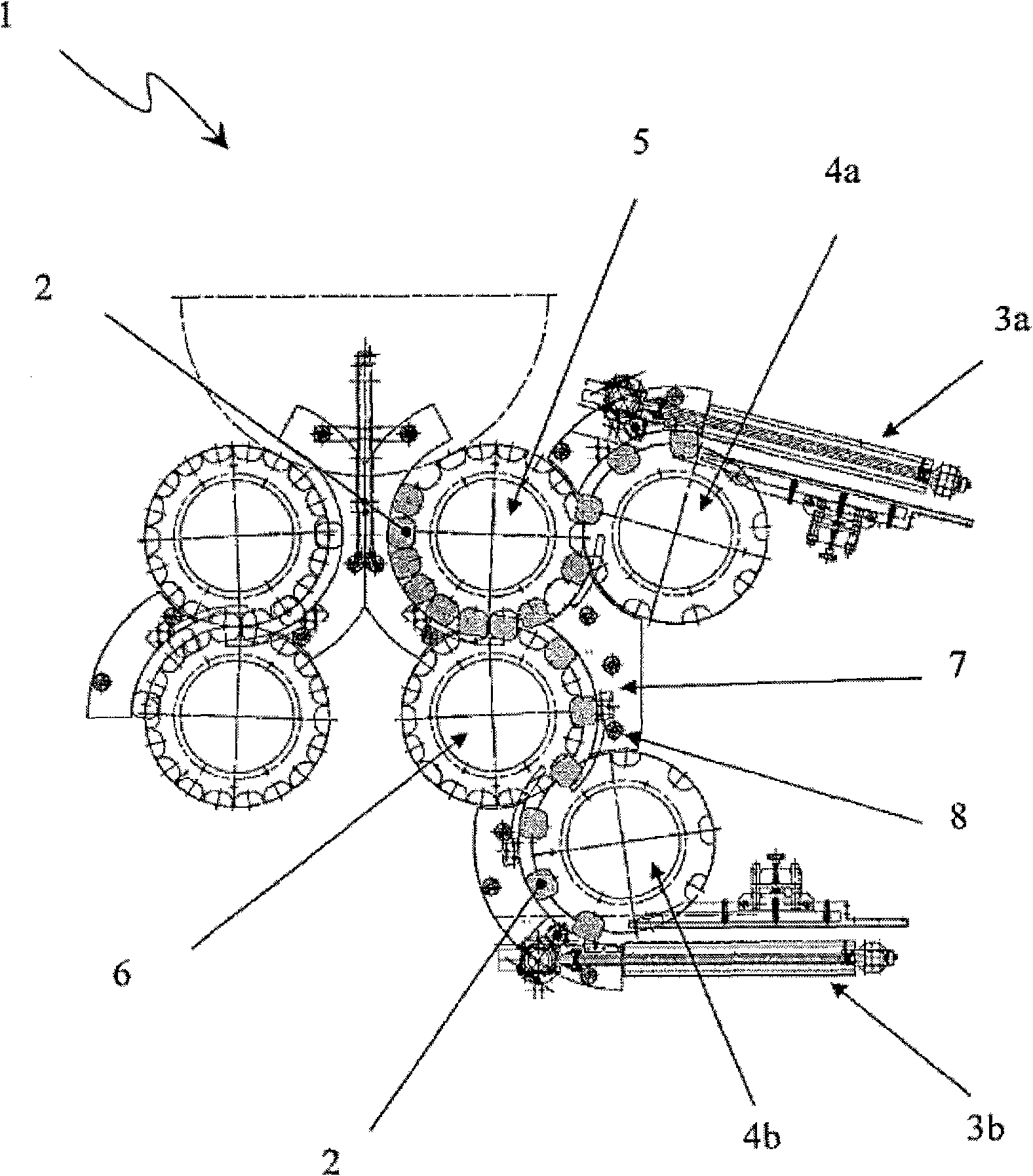

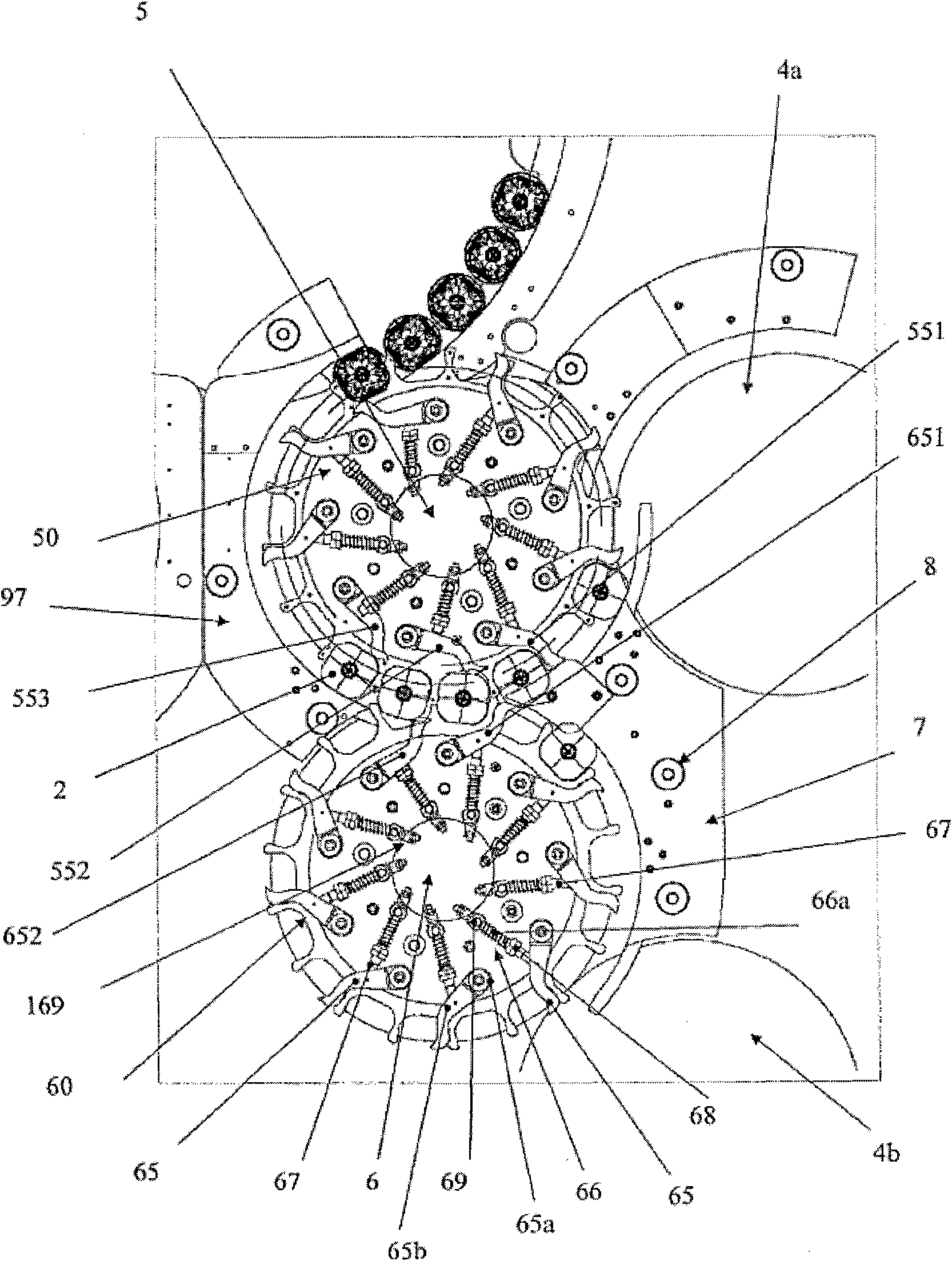

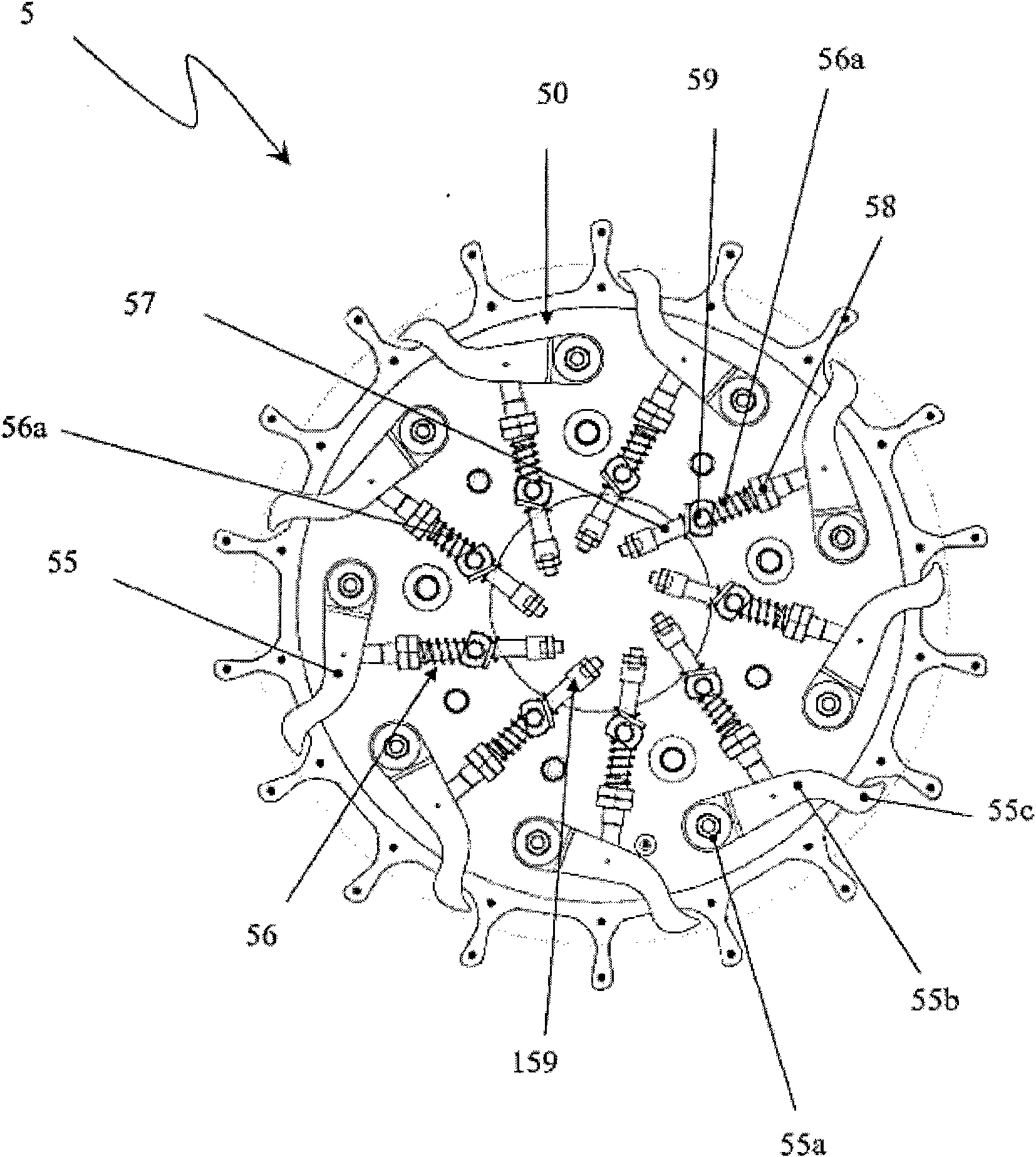

[0016] Referring to the drawings, reference numeral 1 designates as a whole a device for transporting containers 2 having a non-circular cross-section, which in the illustrated embodiment are bottles.

[0017] The device 1 comprises a first input conveyor 3a, which conveys the containers via a first star-wheel 4a to the next re-uniting star-wheel (re-uniting star-wheel) 5; the device 1 also comprises a second input conveyor 3b, which 3b sends the container to the auxiliary starwheel 6 via the second starwheel 4b. In the illustrated embodiment, the input conveyors 3a and 3b are linear conveyors.

[0018] In a particular case, said agglomerating starwheel 5 constitutes an output conveyor on which two drums of different conveying streams from the first and second input conveyors 3a, 3b are reunited, while the auxiliary starwheel 6 constitutes an outlet conveyor with said agglomerating starwheel. Wheel 5 cooperates with the intermediate transporter.

[0019] see figure 1 and 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com