Handle connecting device for cooker

A connecting device and handle technology, which is applied in household utensils, kitchen utensils, applications, etc., can solve the problems of inconvenient use or cleaning, shedding of solder joints, and unsightly appearance, so as to achieve convenient use and cleaning, firm and reliable connection, and not easy to hide The effect of dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

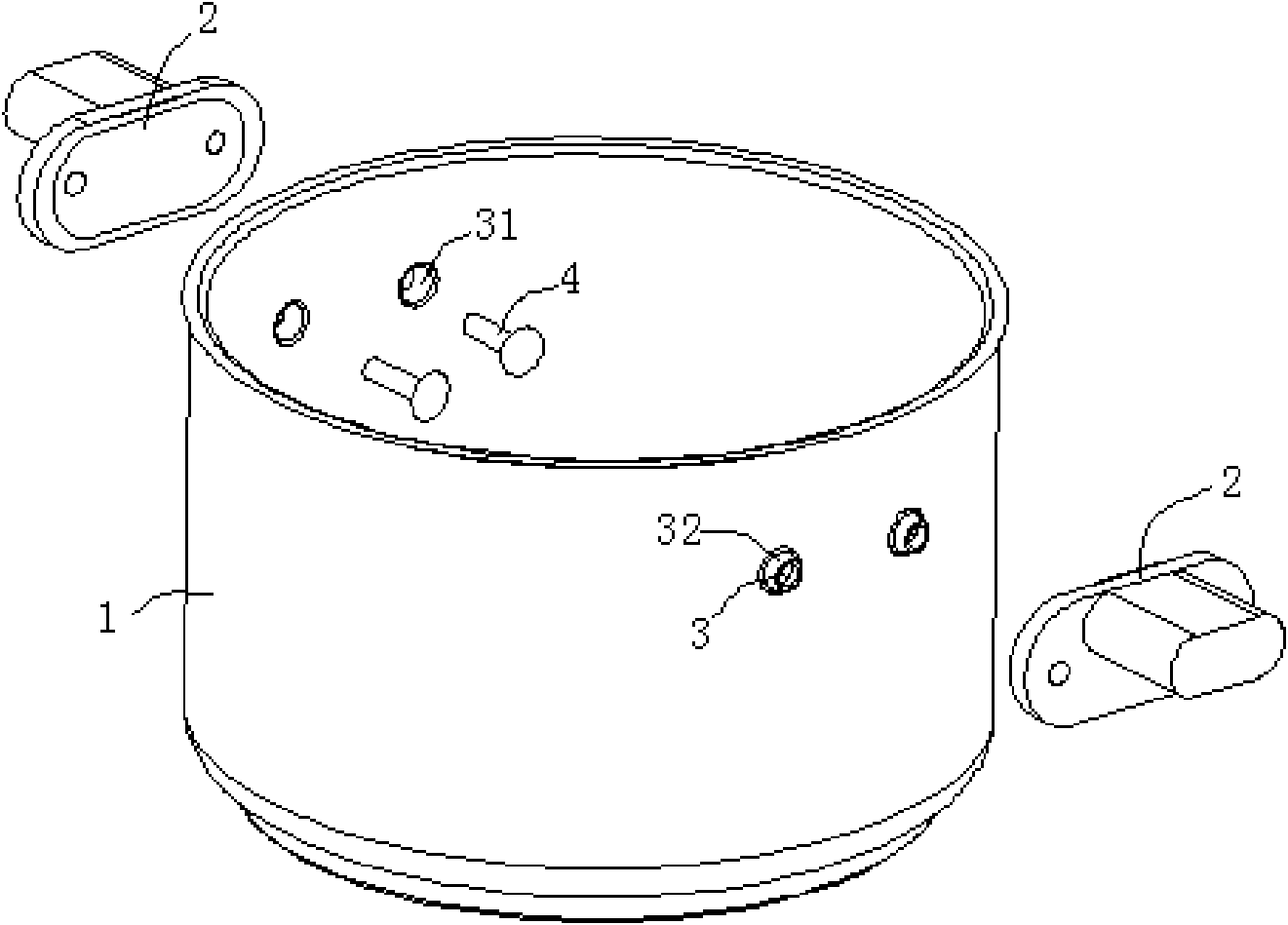

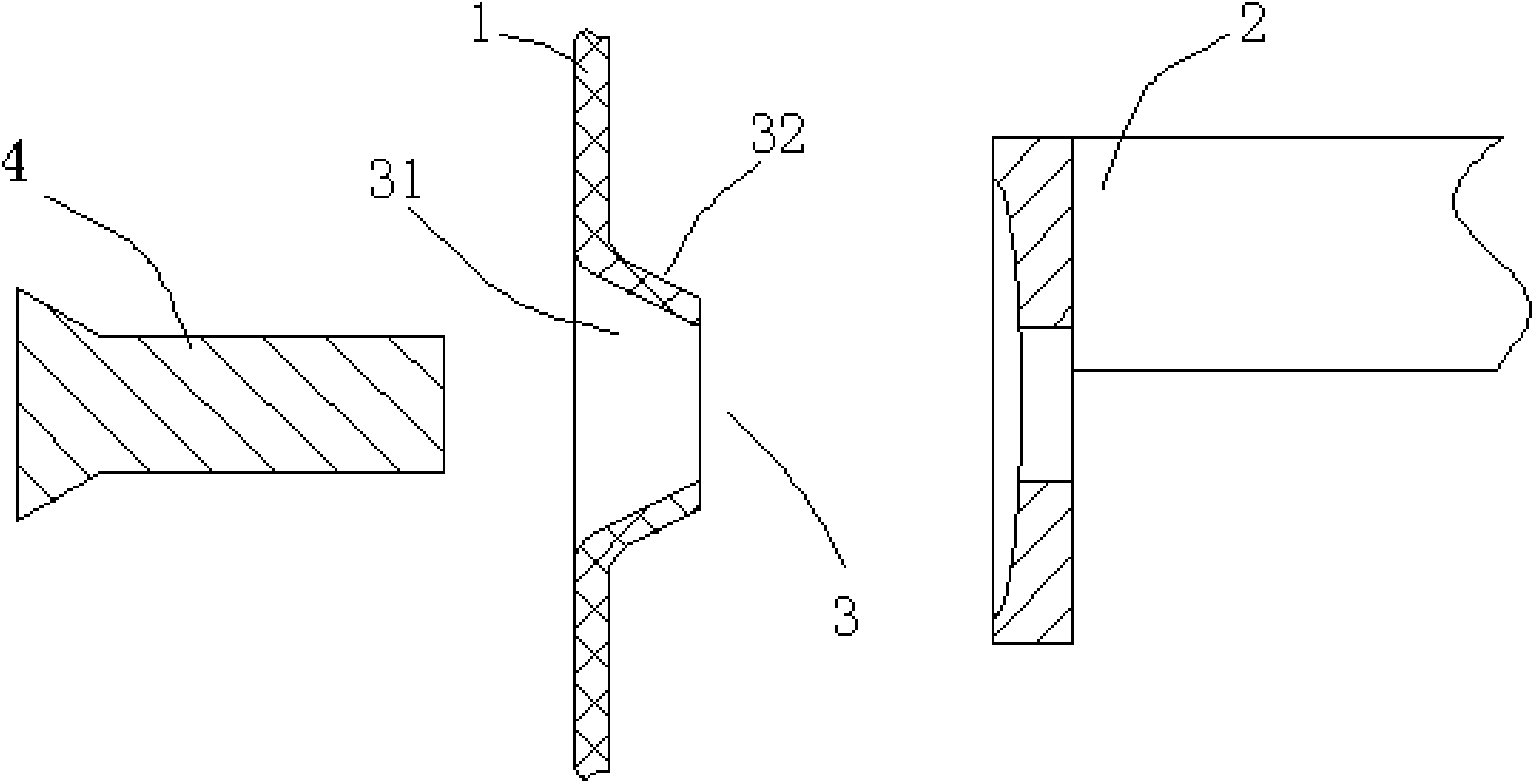

[0010] refer to figure 1 , figure 2 As shown, the handle connection device for cooking utensils includes a body 1 and a handle 2. The body can be a pot body such as a cooking pot or a frying pan or the main body of a pot, or a pot cover. The side wall of the body 1 is provided with at least one installation The through hole 3 of the handle 2, the through hole 3 is a tapered bell mouth that protrudes outward from the periphery. During production, the inner wall of the thinner main body is punched outward by stamping technology to form the concave part 31 inside the through hole 3 and the outer part. The concave part 31 and the protruding part 32 , the body 1 and the handle 2 are fixed through the connecting piece 4 arranged in the through hole 3 .

[0011] The connector 4 is a rivet. Since the inner side of the through hole 3 is a concave portion 31, the head of the rivet can be embedded in the concave portion 31 during assembly, so that the accessories at this position will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com