Dual-function braking device combining air pump resilience with friction

A friction bonding and braking device technology, applied in electric vehicles, vehicle parts, transportation and packaging, etc., can solve the problems of high cost of electric energy conversion devices, low energy utilization rate, large energy recovery devices, etc., to make full use of energy, structural Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Attached below Figure 1~4 And embodiment further illustrate the present invention.

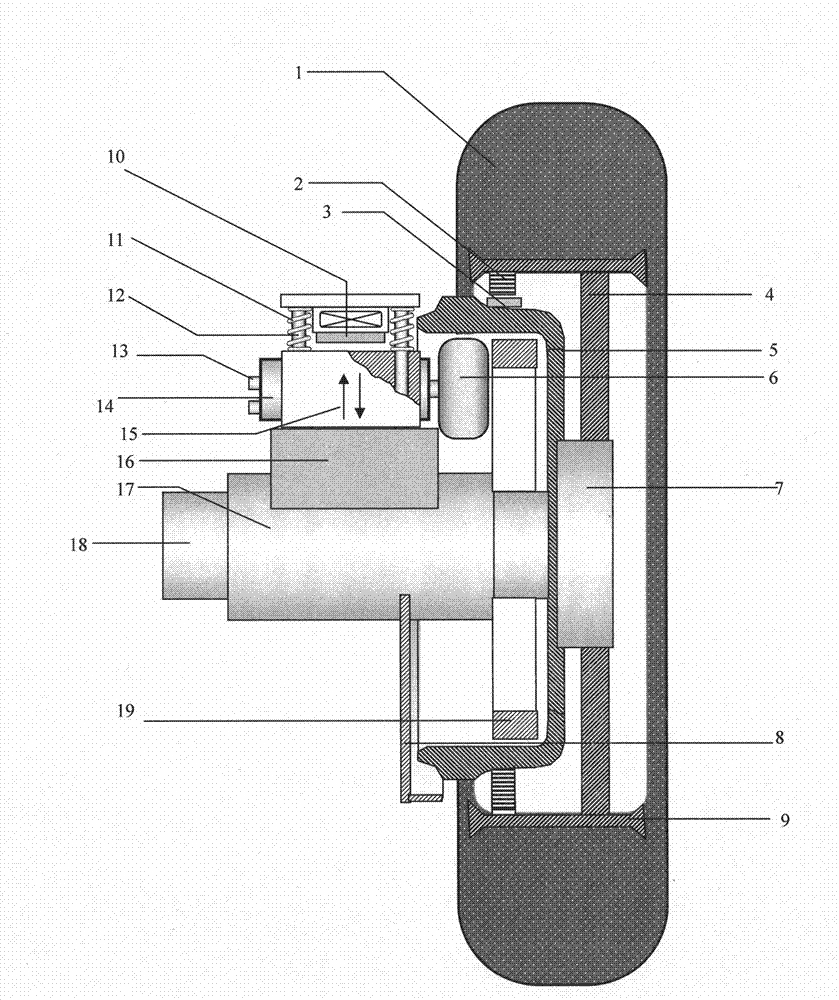

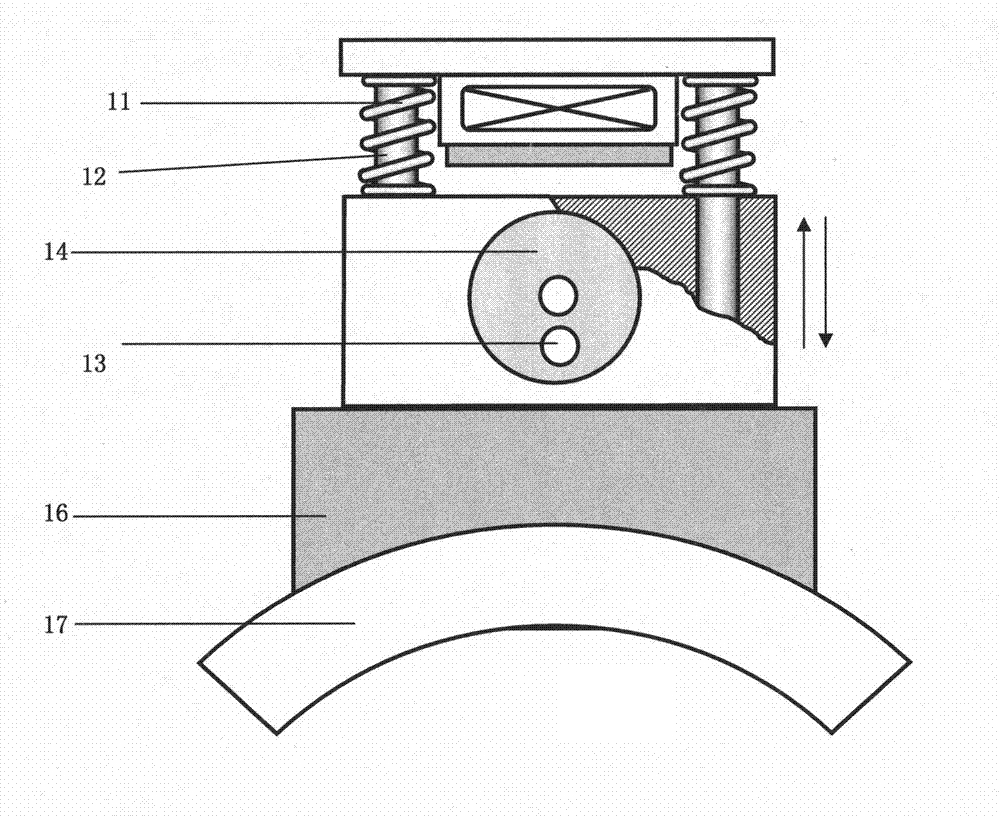

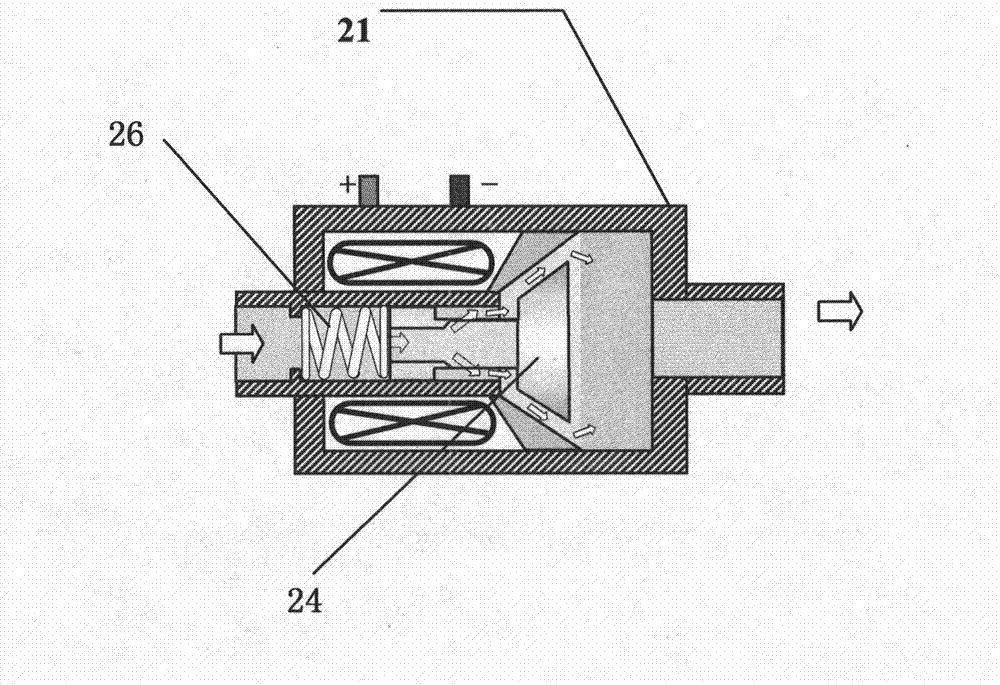

[0019] see figure 1 , 2 , The mechanical braking of this device still adopts the braking structure of a traditional vehicle, that is, the brake drum 5 and the axle disc 7 are fixed as one, and the brake shoes 19 are installed in the brake drum 5 cavities. The electronically controlled air pump return energy braking mechanism of this device is that the air pump 14 is fixed on the sliding seat 15, and the sliding seat 15 is installed on the sliding shaft 12. The sliding shaft 12 is perpendicular to the axle 18, and four symmetrically fixed on the fixed seat 16. On, the fixed seat 16 is fixed on the axle bearing 17 again, and the moving end of the sliding shaft 12 is installed with the electromagnet 10 by the support, and the return spring 11 is pressed between the support of the electromagnet and the sliding seat 15. The rotating shaft of air pump 14 extends in the brake drum 5, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com