Petroleum expansion pipe hanger and construction technology

A technology of expansion pipe and hanger, applied in wellbore/well components, earth-moving drilling, etc., can solve the problems of insufficient suspension force, seal leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

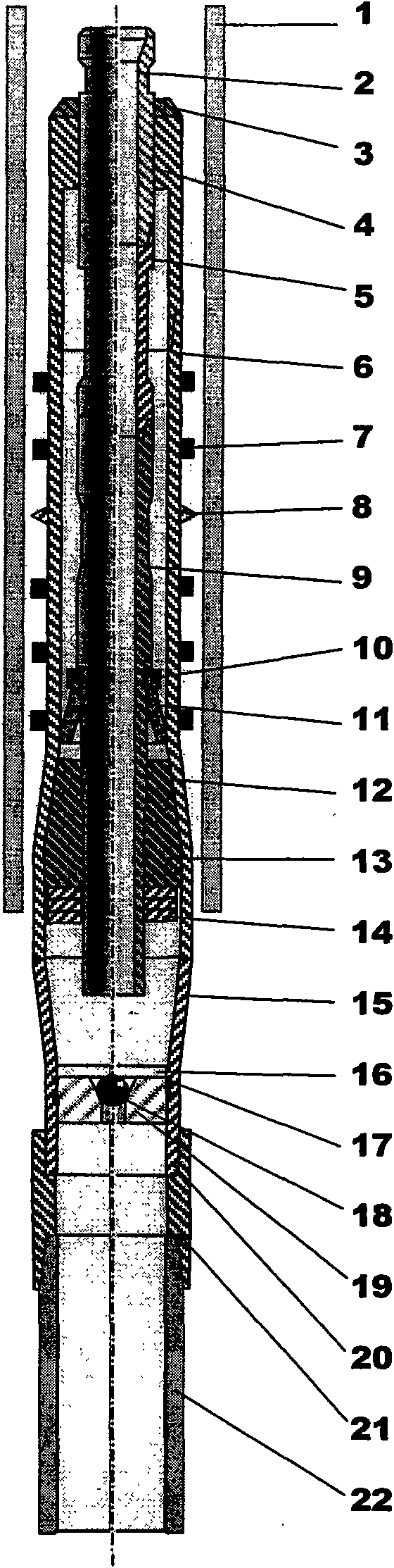

[0007] In the figure, the expansion tube hanger is composed of a drill string, an expansion suspension body, a length-adjusting rotary sleeve set, an expansion launch chamber and a liner connection. , Push-pull central tube 9 and bearing nut 14 are formed. Adjust the connection between the upper box of the righting nipple and the pin of the upper drilling tool, and the connection of the lower pin and the box of the transitional drill pipe, and adjust the relative position of the lengthening swivel through the thread. The male buckle at the lower end of the transition drill rod is connected with the female buckle at the upper end of the push-pull center pipe. The lower step of the push-pull central tube is equipped with an expansion head, and the expansion head is compressed by the bearing nut group. The middle part of the push-pull center tube is equipped with a push piston through a traction cap. Said expansion tube suspension body is made up of sleeve pipe 1, suspension pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com