Outdoor dynamic testing method for heat-insulation property of heat-insulation coating at outer wall of building

A heat-insulating coating and dynamic testing technology, which is applied in the direction of material thermal development, material thermal conductivity, etc., can solve the problems of inability to test and analyze the impact of heat-insulating coating building energy consumption, etc., and achieve the effect of accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

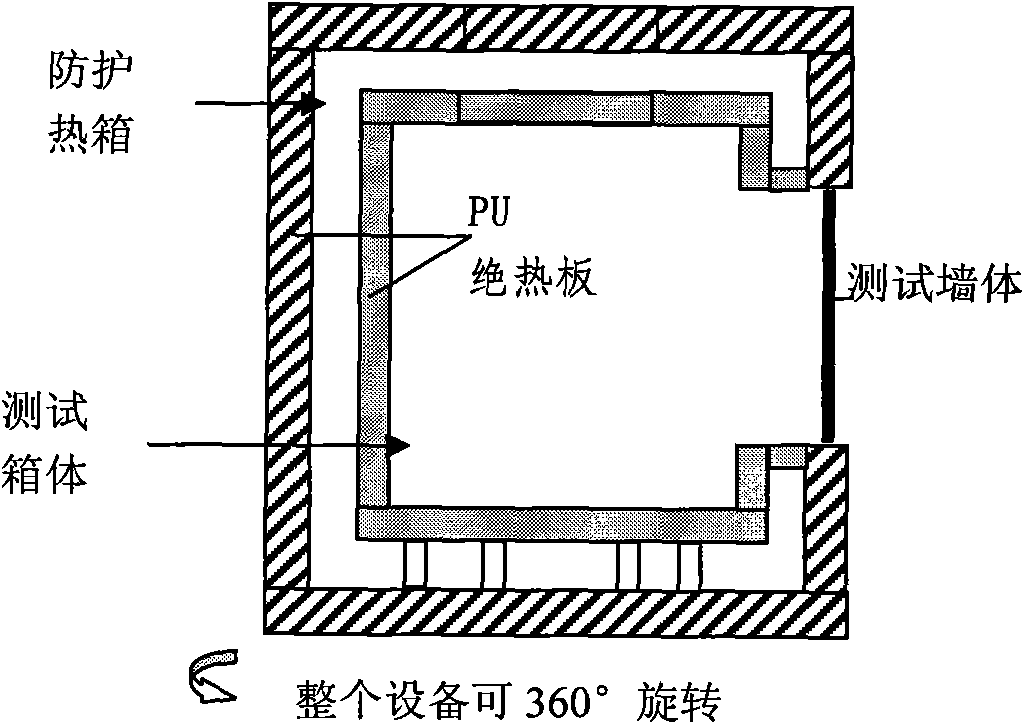

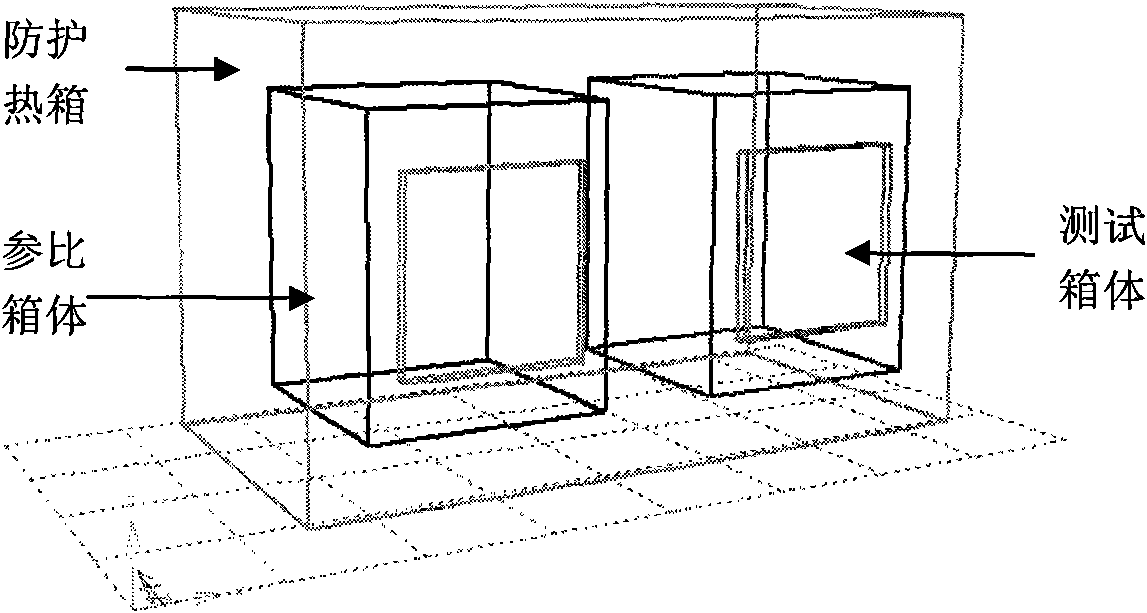

[0034] The specific embodiment of the present invention is to place a protective hot box on a turntable that can rotate 360°; the test box and the reference box are placed in the protective hot box on five sides except the test surface; in the test box The test and reference base wall and the test and reference samples are made on the test surface of the reference box; adjust the temperature in the test box, the reference box and the protective hot box to 24°C; adjust the test box The wind speed on the inner surface of the test surface of the test body and the reference box is less than 0.3 m / s; the thermal insulation performance of the tested sample is obtained under actual outdoor conditions.

[0035] The material of the protective hot box is polyurethane, and the thickness of the box body is 10 cm. The length of the test box and the reference box is 2 meters, the width is 2 meters, and the height is 2.4 meters. There are square openings with a side length of 1.5 meters on the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com