Precast concrete beam

A prefabricated concrete and concrete technology, applied in the direction of joists, girders, trusses, etc., can solve the problems of low construction efficiency and construction quality risks, and achieve the effect of avoiding falling off and ensuring construction quality and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

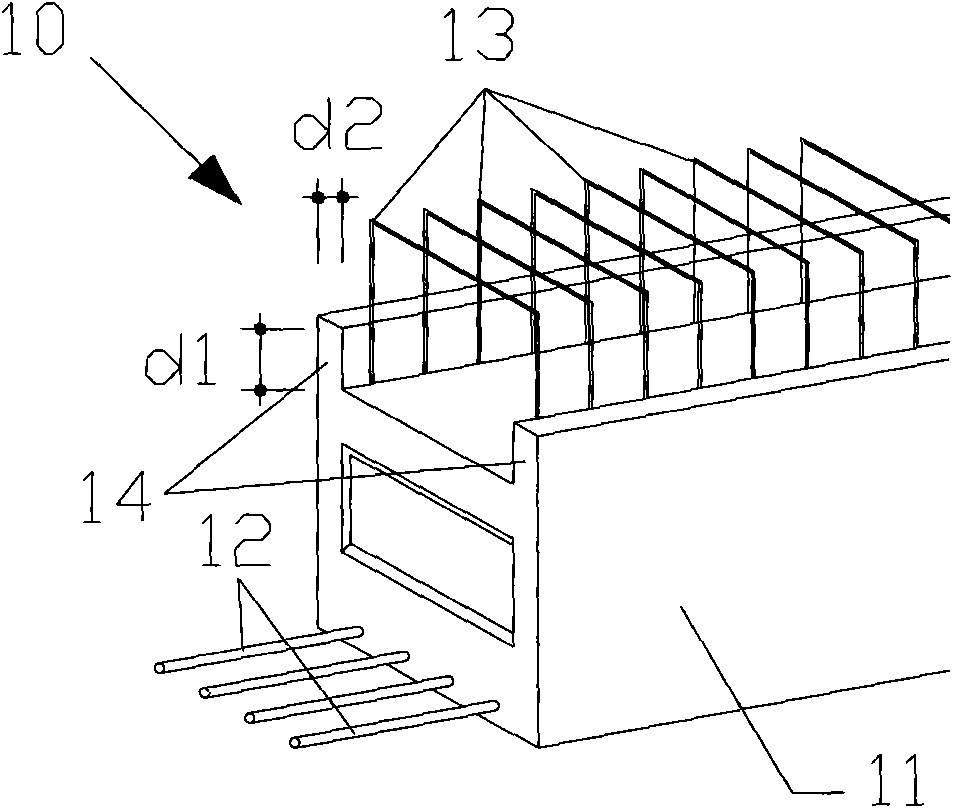

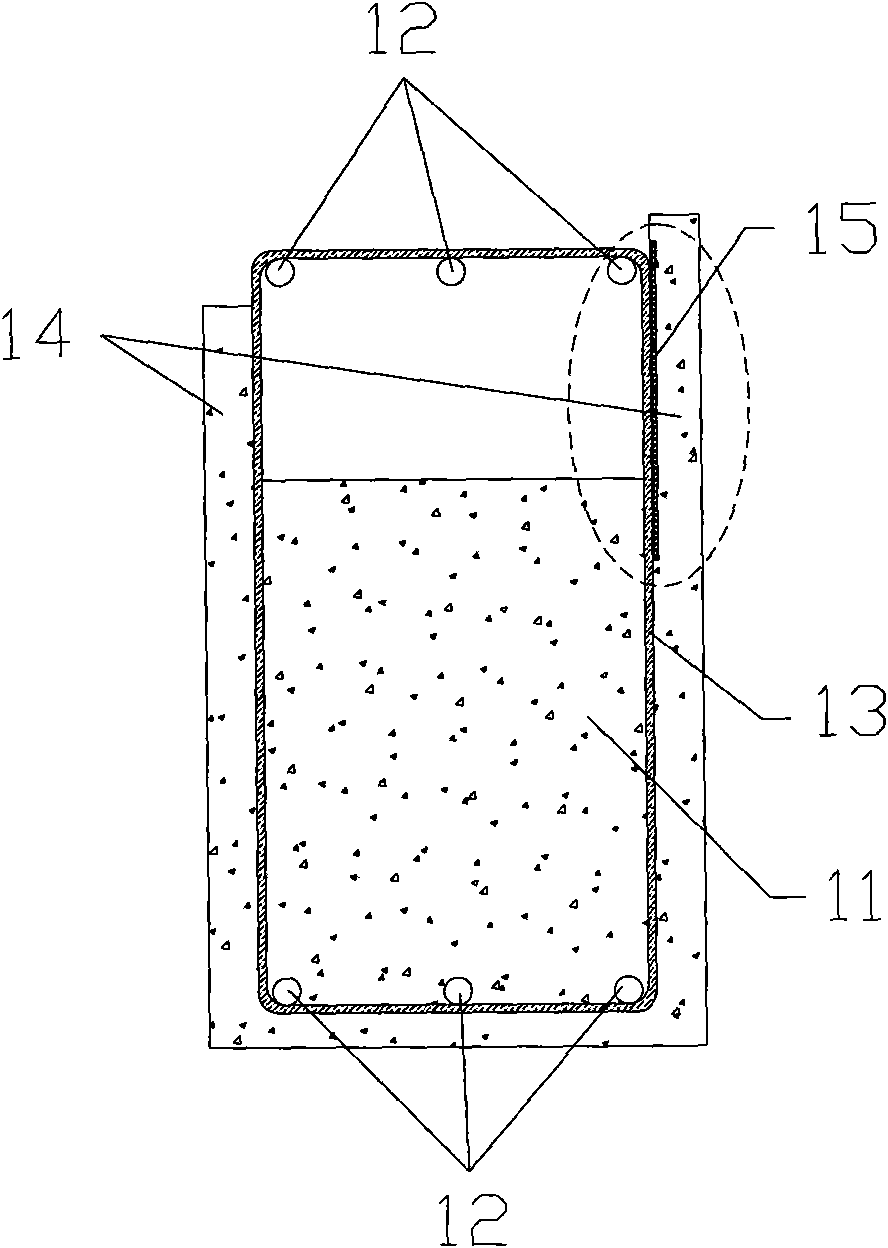

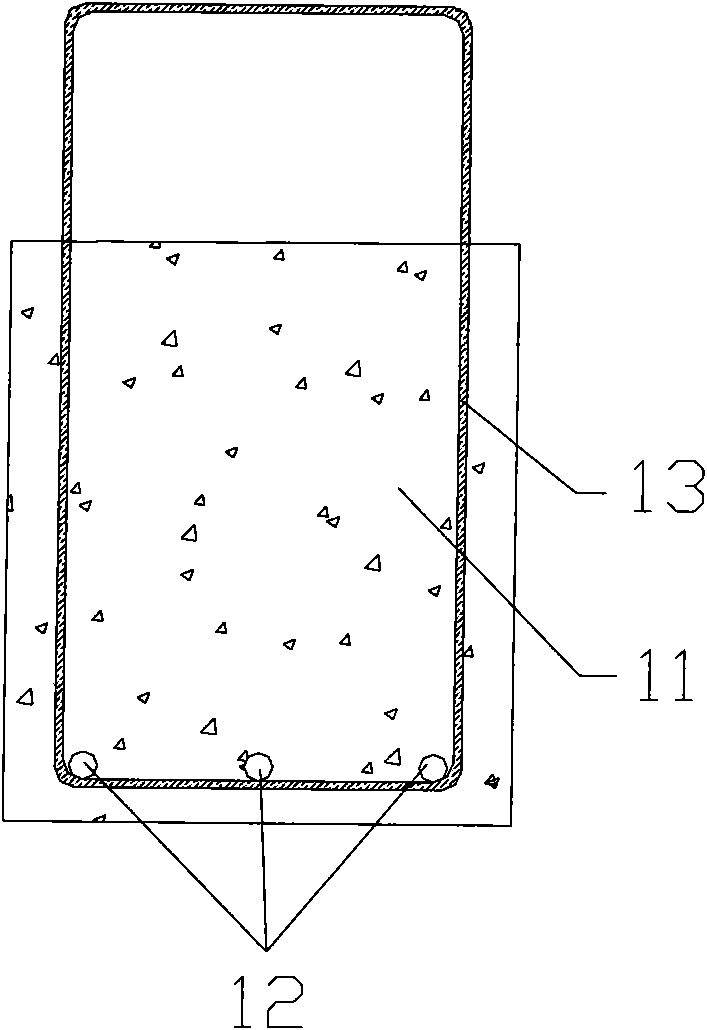

[0021] Such as Figure 1-3 Shown is a schematic structural view of a prefabricated concrete beam embodiment of the present invention. The prefabricated concrete beam includes a beam body 10 composed of main bars 12 , stirrups 13 and concrete 11 .

[0022] The main bars 12 are multiple parallel bars arranged along the length direction of the beam body 10 , and only the ends of the beam body 10 are exposed. The stirrup 13 is rectangular, including a vertical part and a horizontal part. The plane of the frame-shaped stirrup 13 is perpendicular to the main reinforcement 12 , that is, perpendicular to the length direction of the beam main body 10 . Each of the above-mentioned stirrups 13 can be formed by bending a steel bar. A plurality of main reinforcements 12 are fixed on the horizontal part of the bottom of the stirrups 13 and poured into the concrete 11. The above-mentioned fixing can be welding or steel wire binding. A plurality of main reinforcements can also be fixed at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com