Water injector for automatically balancing downhole flow of oilfield

A technology of automatic balance and water injector, which is applied in the direction of production fluid, borehole/well parts, borehole/well valve device, etc. It can solve the problems of unable to realize quantitative water injection, achieve good self-stabilization ability, improve water injection quality, The effect of good dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

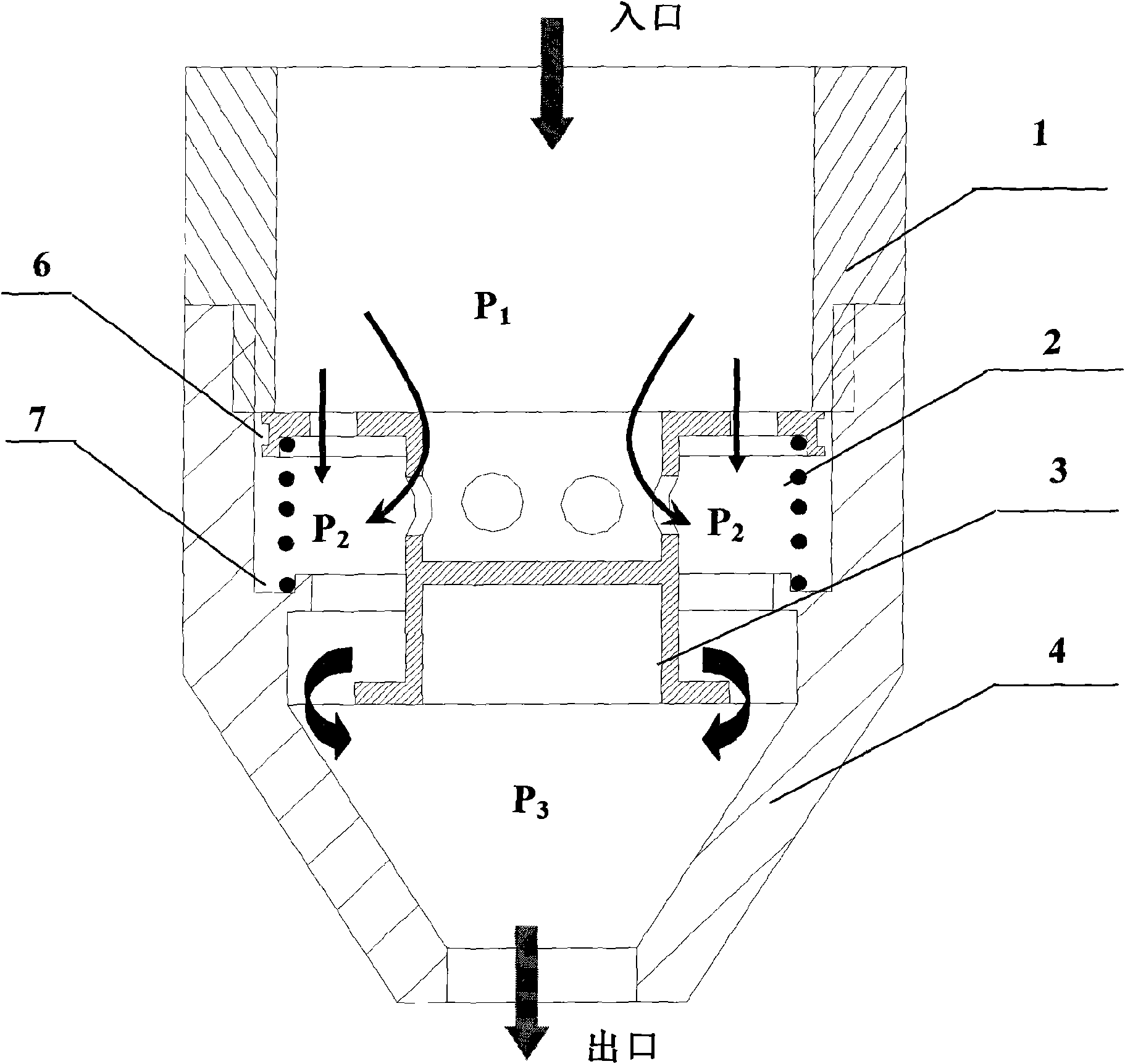

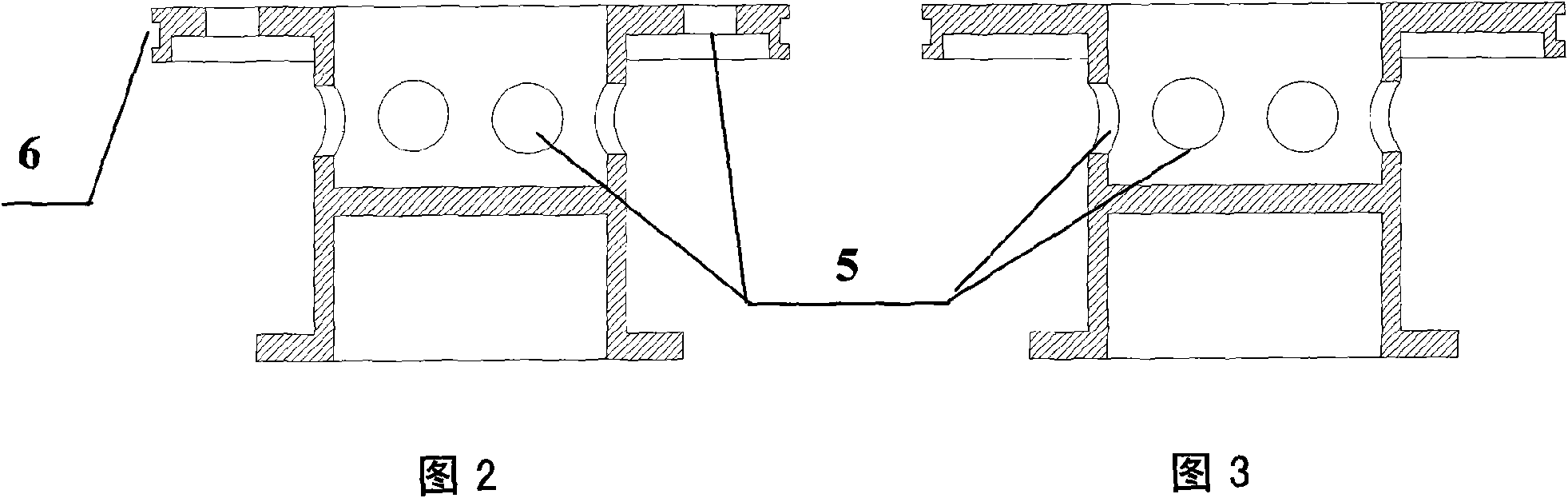

[0011] Such as figure 1 , the present invention includes a valve body 4 and an axisymmetric valve core 3 therein, which is characterized in that a spring 2 is installed on an annular groove 7 on the inner wall of the valve body 4 in a tapered cavity to support the lower end surface of the valve core 3, and the valve core The upper end surface of the valve core 3 is compressed by the locking cap 1 connected with the thread, and the upper end side of the valve core 3 is provided with a decompression groove 6, and at least two orifices 5 are symmetrically distributed around the wall surface of the upper cavity of the valve core 3. The total area of the orifice 5 is consistent with the design requirements of the water injection flow, and the locking cap is threadedly connected with the valve body, and the lower end surface of the locking cap presses the upper end surface of the spool. Considering that the water injection volume is required to be large and the area of the orifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com