Intelligent wind wheel used for vertical axis wind generating device

A wind power generation device, vertical axis technology, applied in the direction of wind power generator components, wind power engine control, wind power generation, etc., can solve the problems of low efficiency, large aerodynamic noise, difficult maintenance, etc., to achieve cost reduction, low aerodynamic noise, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

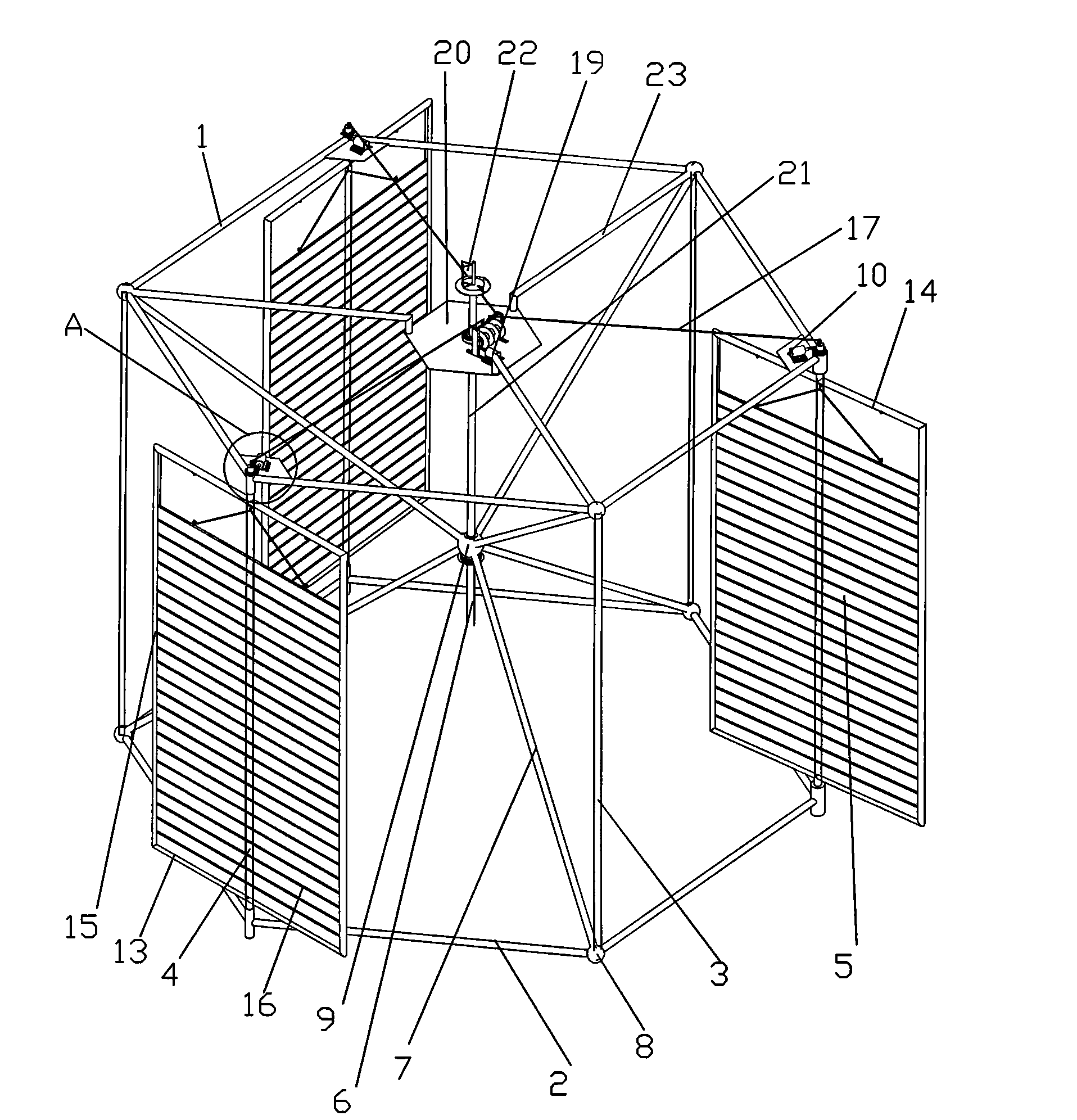

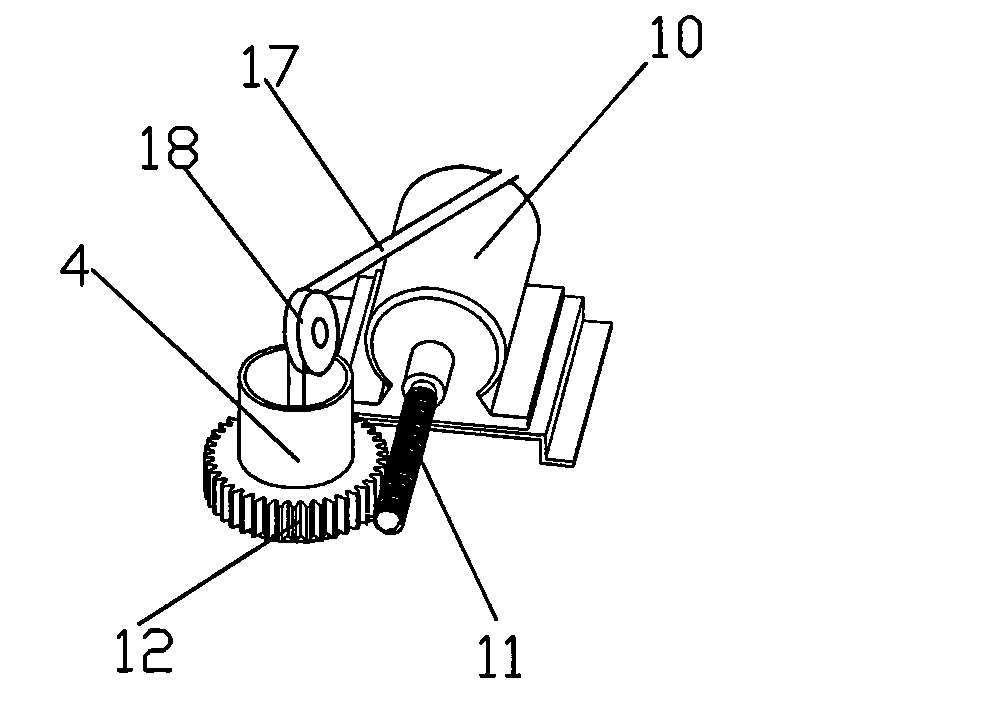

[0024] Such as figure 1 As shown, the present invention is an intelligent wind rotor for a vertical axis wind power generation device, comprising an upper rim 1 and a lower rim 2, three support rods 3 and three blade shafts 4 are arranged between the rims, and the blade shafts 4 is provided with 3 sails 5, and the wheel rim, support rod 3 and blade shaft 4 form a positive prism, and the middle part of the positive prism is provided with a wheel shaft 6, and a wheel hub 7 is arranged between the wheel shaft 6 and the wheel rim, and the upper and lower wheel rims 1 and 2 are regular polygons with 6 sides, the vertices of two adjacent sides are provided with connectors 8, and the support rods 3 and blade shafts 4 are arranged in the connectors 8 corresponding to the vertices of the upper and lower rims 1 and 2, The top of the wheel shaft 6 is provided with a fixed body 9, and the hub 7 is arranged between the fixed body 9 and the connecting body 8; the support rod 3 and the blade...

Embodiment 2

[0028] In Embodiment 1, a middle rim is provided between the upper rim and the lower rim, and the three rims are regular polygons with 8 sides, and 4 support rods and 4 blade shafts are arranged between the rims, and the blade shafts There are 4 pairs of sails on the upper rim, a hub is arranged between the connecting body connecting the blade shaft and the fixed body on the middle rim, and a hub is arranged between the connecting body connecting the support rod on the upper and lower rims and the fixed body. The sail ropes of 4 pairs of sails are respectively connected with 4 motors. Each motor is located on the hub of the middle rim, the fixed body is provided with a rod 21, and the top of the rod 21 is provided with a wind direction indicator 22, and the others are the same as in Embodiment 1.

Embodiment 3

[0030] The rim in Embodiment 1 is a regular 12-gon, and 6 support rods 3 and 6 blade shafts 4 are arranged between the rims, and each blade shaft 4 is provided with a sail 5, and the others are the same as in Embodiment 1. .

[0031] Working principle of the present invention: the canvas of the present invention can be lifted and lowered according to the size of the wind, and the blade shaft can be adjusted according to the wind direction at any time. The angle adjustment motor can adjust the angle of the blade shaft according to the instruction of the sail controller, and the The code transmits the angle of the blade shaft through the code reader to the sail controller to calculate the angle that should be adjusted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com