Combined type water tap

A faucet and combined technology, applied in the field of faucets, can solve the problems of rough connection appearance, yellowing of the surface of the contour part, affecting product quality, etc., and achieve the effect of clear appearance, simple processing, and easy manufacturing and control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

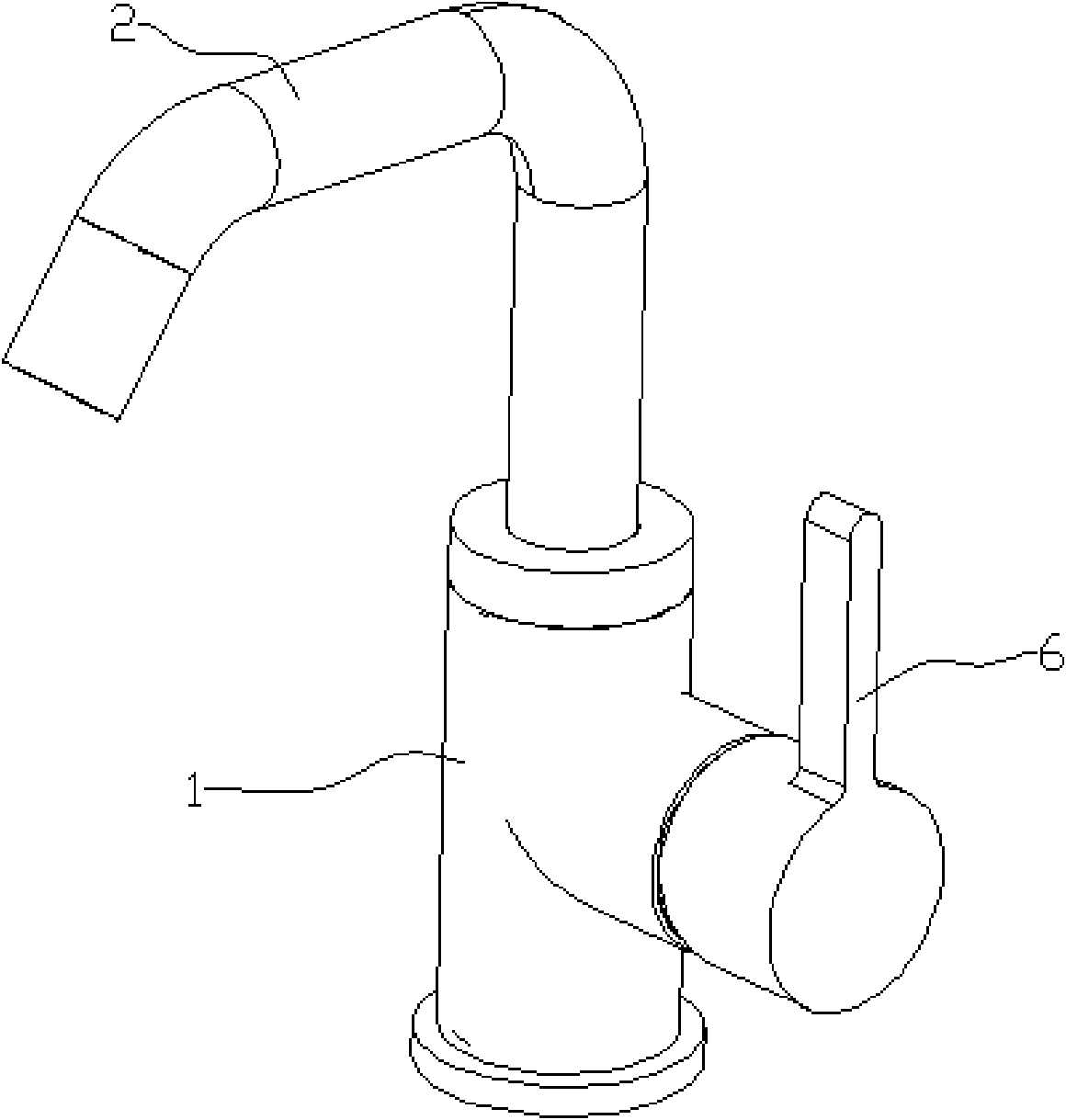

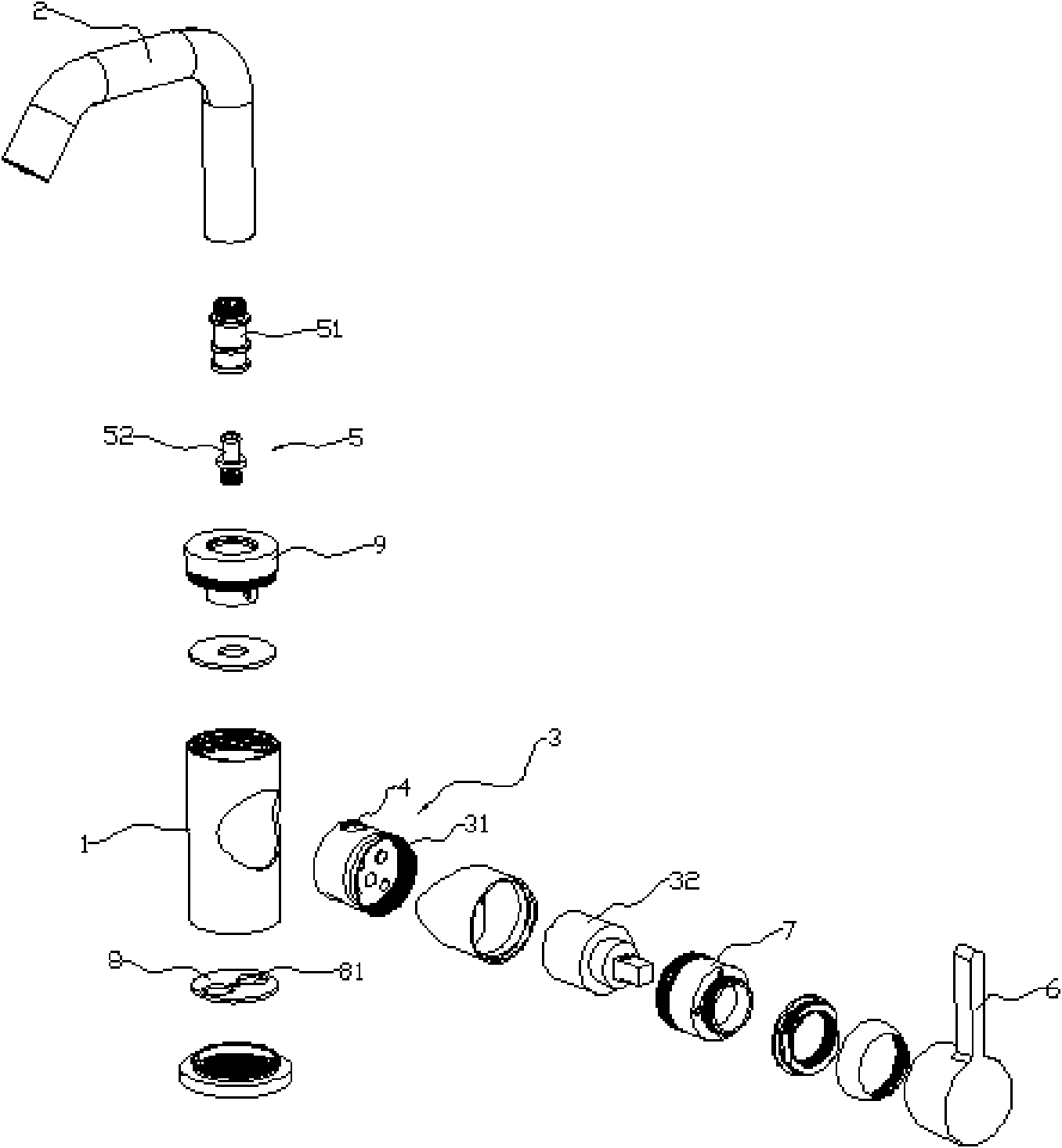

[0012] refer to Figure 1 to Figure 3 , a combined faucet of the present invention includes a valve body 1, an outlet pipe 2 and a valve core 3, the valve core 3 is installed inside the valve body 1, and a threaded hole 4 is opened on the valve core 3, and the threaded hole 4 A connecting head 5 is installed in the middle, and one end of the connecting head 5 is connected with the water outlet pipe 2 through threads, and a handle 6 for controlling the opening and closing of the valve core 3 is provided outside the valve body 1 . Because the combined water faucet adopts the above-mentioned structure, all parts are combined through threaded connection, the processing is simple, the manufacture is convenient and the quality of the product is controlled, and the production cost of the product is reduced.

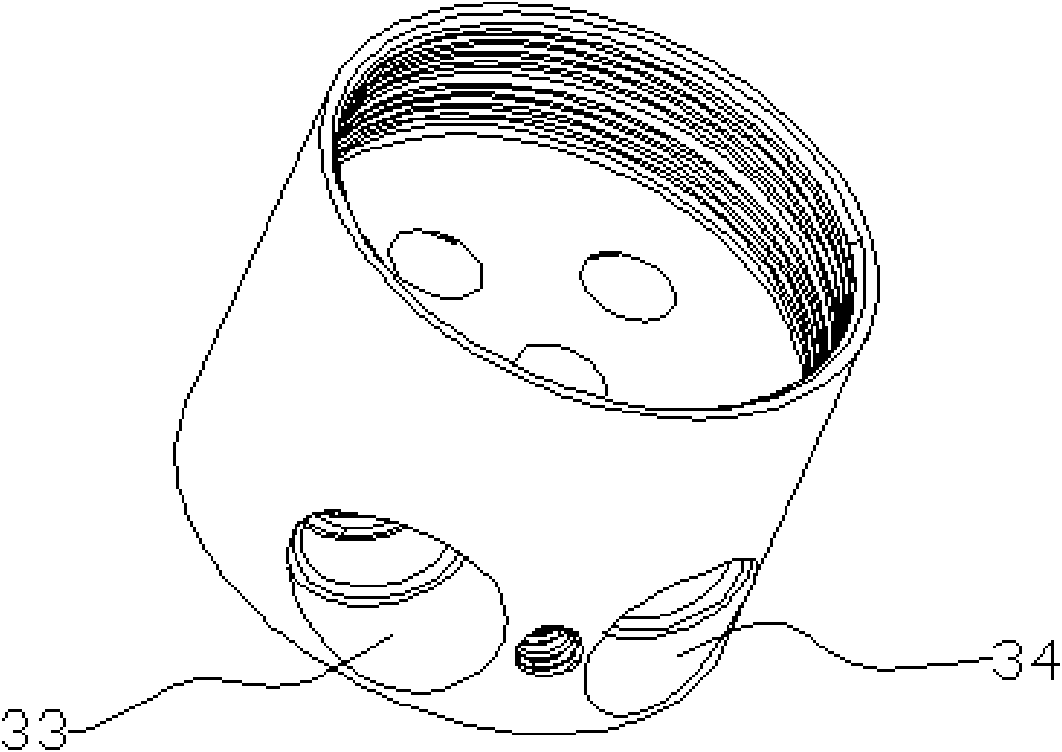

[0013] The valve core 3 is composed of a water mixing valve core 31 and an adjusting valve core 32, the threaded hole 4 is arranged on the upper part of the water mixing valve c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com