Low-noise electromagnetic switch and making method thereof

A technology of electromagnetic switch and manufacturing method, which is applied to electric switches, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve problems such as passenger discomfort, and achieve the effects of simplifying manufacturing processes, improving manufacturing convenience, and improving convenience and speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] With reference to the accompanying drawings, the purpose, structure and effects of the present invention will be described in detail through ideal embodiments of the present invention.

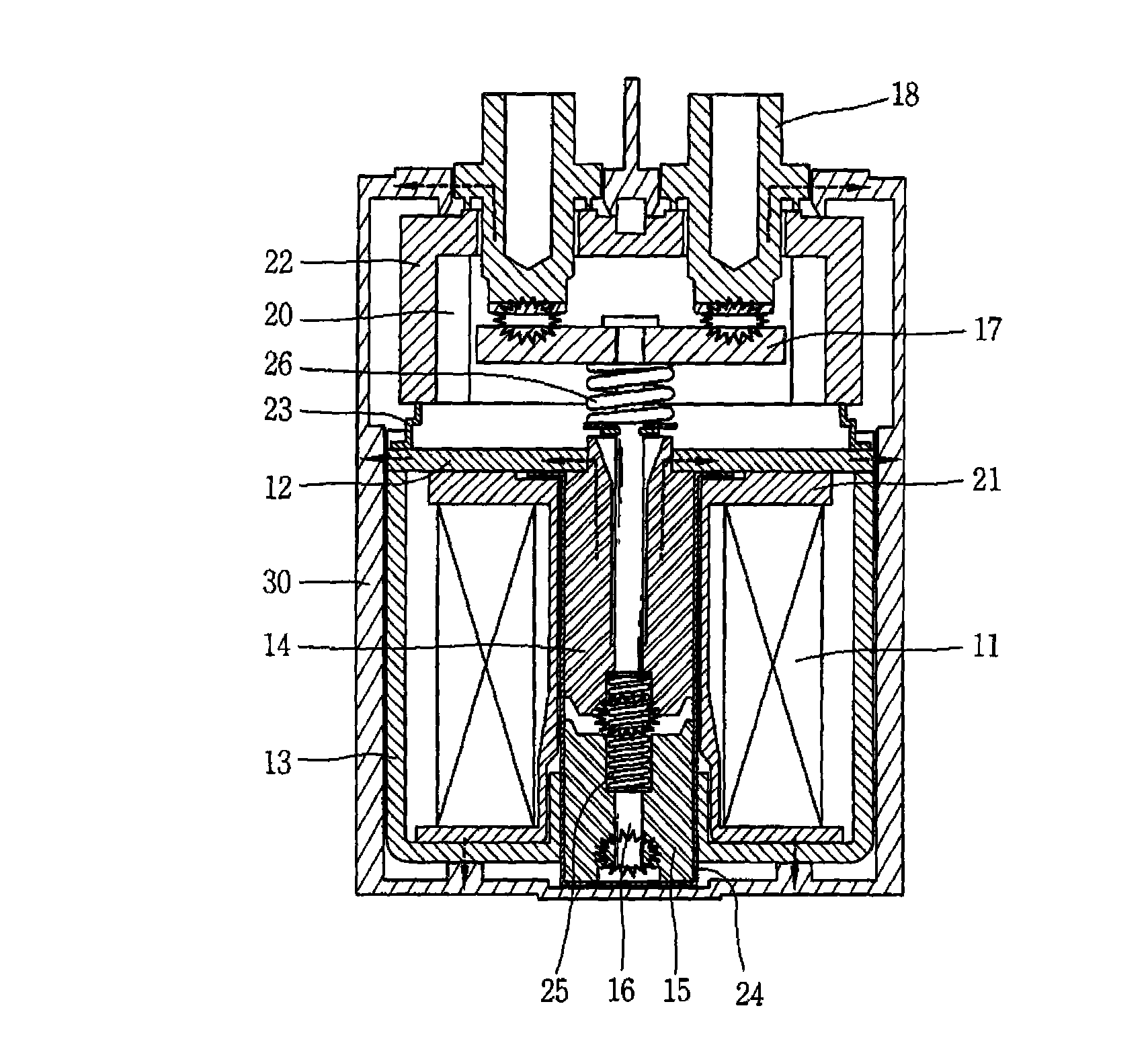

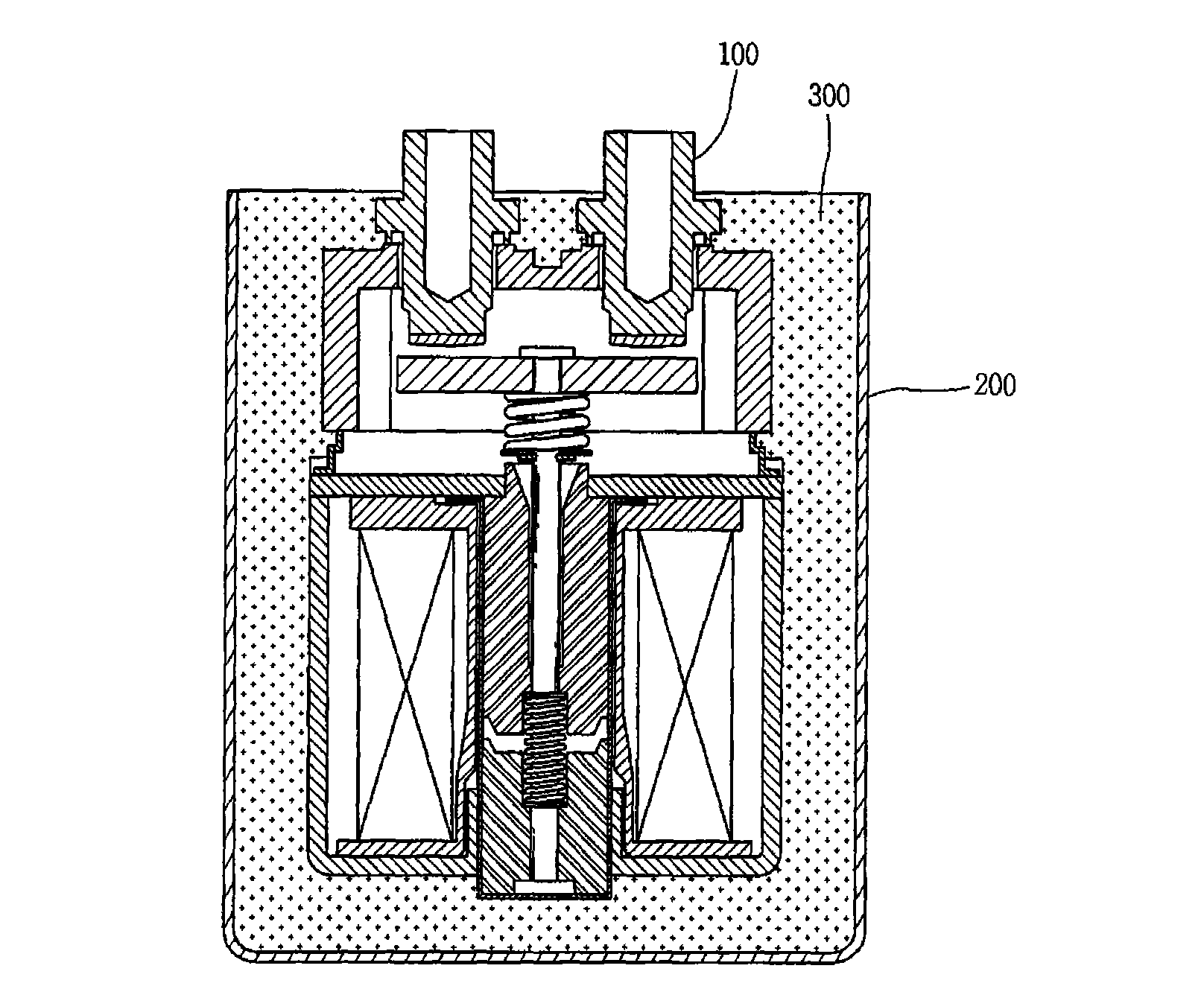

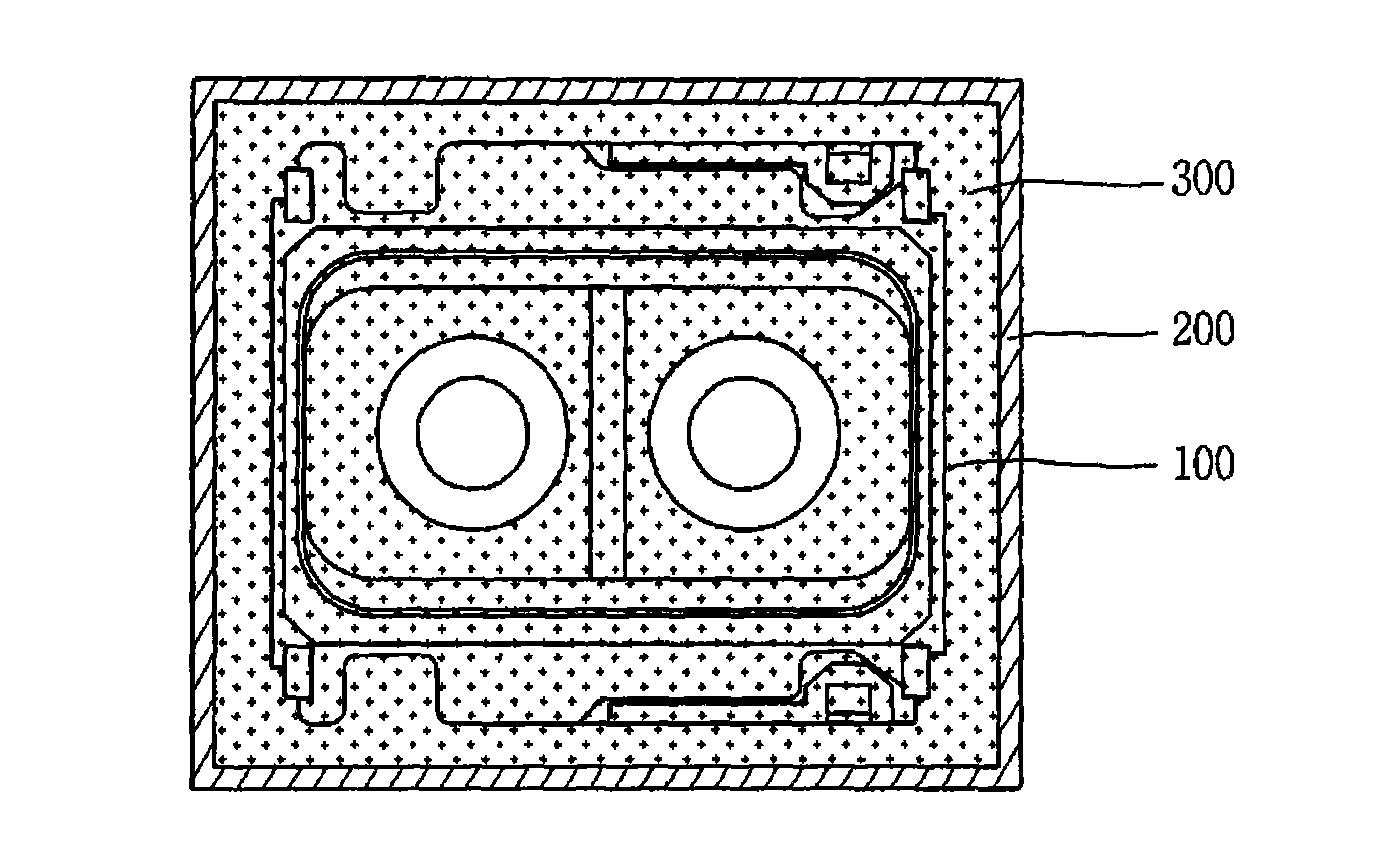

[0071] figure 2 It is a longitudinal sectional view showing the structure of the low-noise electromagnetic switch for direct current breaking in the present invention. image 3 It is a plan view showing the structure of the low-noise electromagnetic switch for DC breaking in the present invention. refer to figure 2 , image 3 The structure of the low-noise electromagnetic switch for DC breaking in the present invention will be described.

[0072] The low-noise electromagnetic switch for DC breaking of the present invention includes a built-in switch 100 , an outer case 200 and a filler 300 .

[0073] The built-in switch 100 includes: a movable part having contacts; a gas sealing part that seals a filling space filled with an arc-extinguishing gas for arc extinguishing; and a magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com