Method for fitting part assemblies

A technology for parts and assemblies, used in the alignment and connection of large and complex parts and assemblies, the field of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

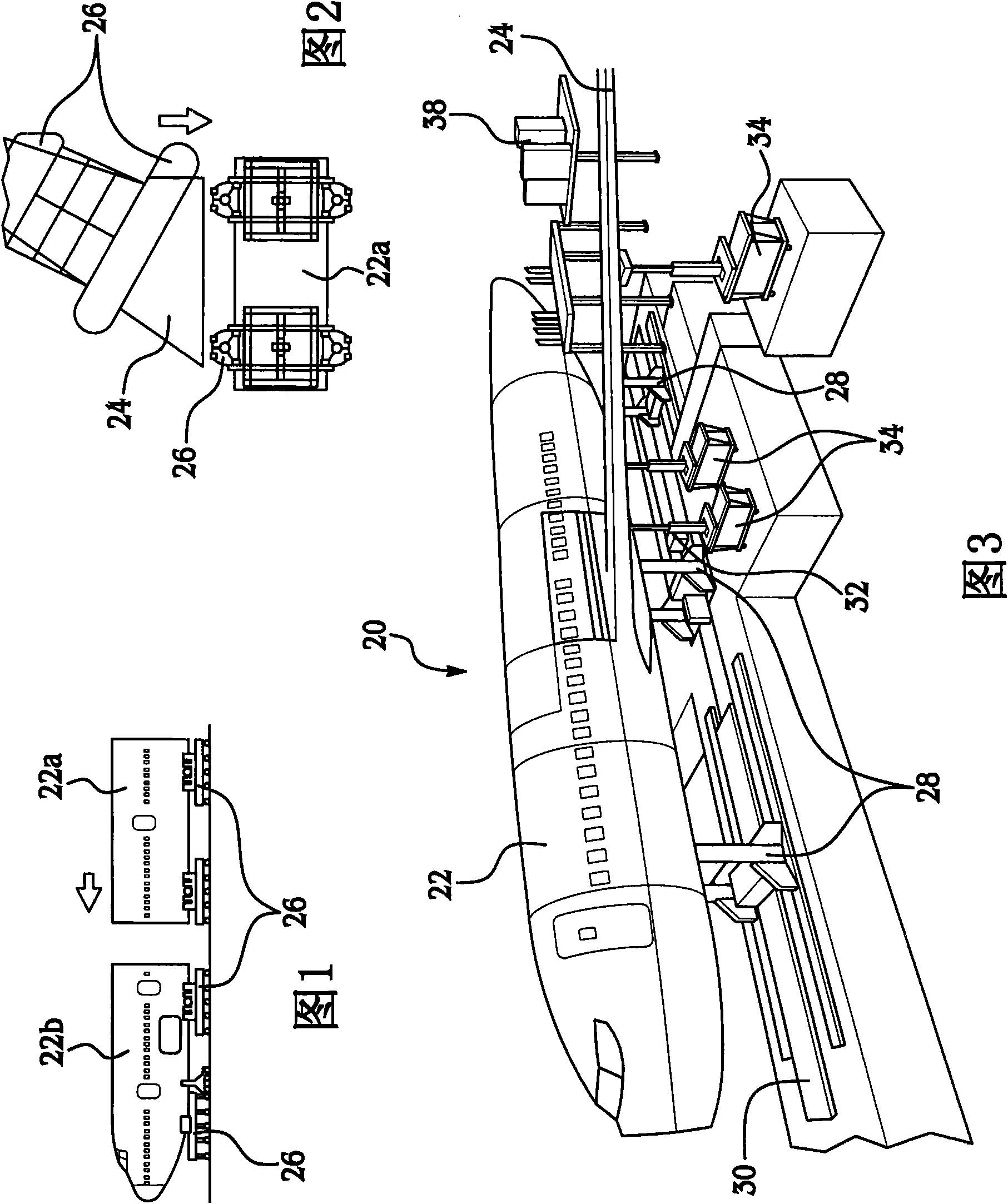

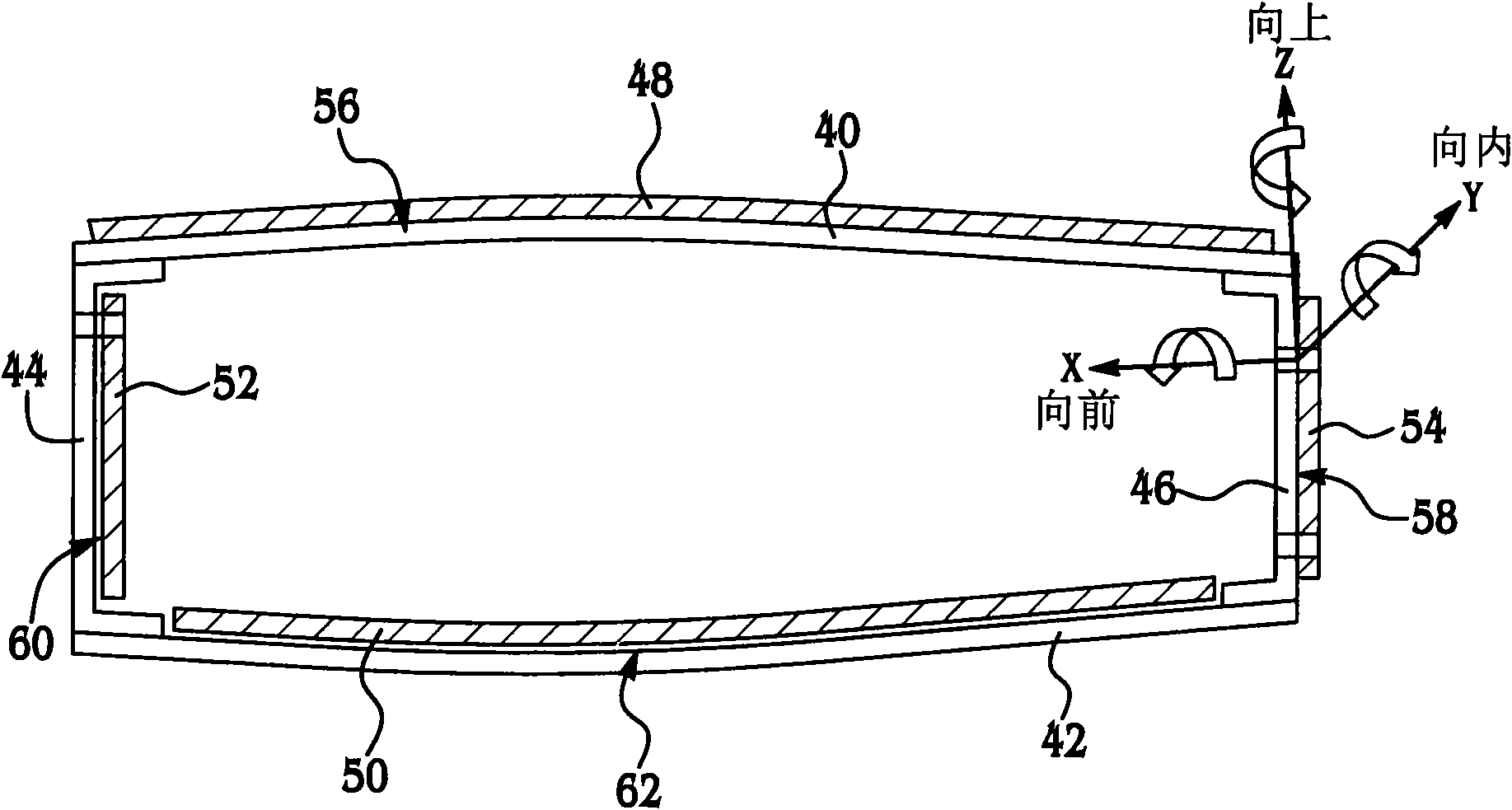

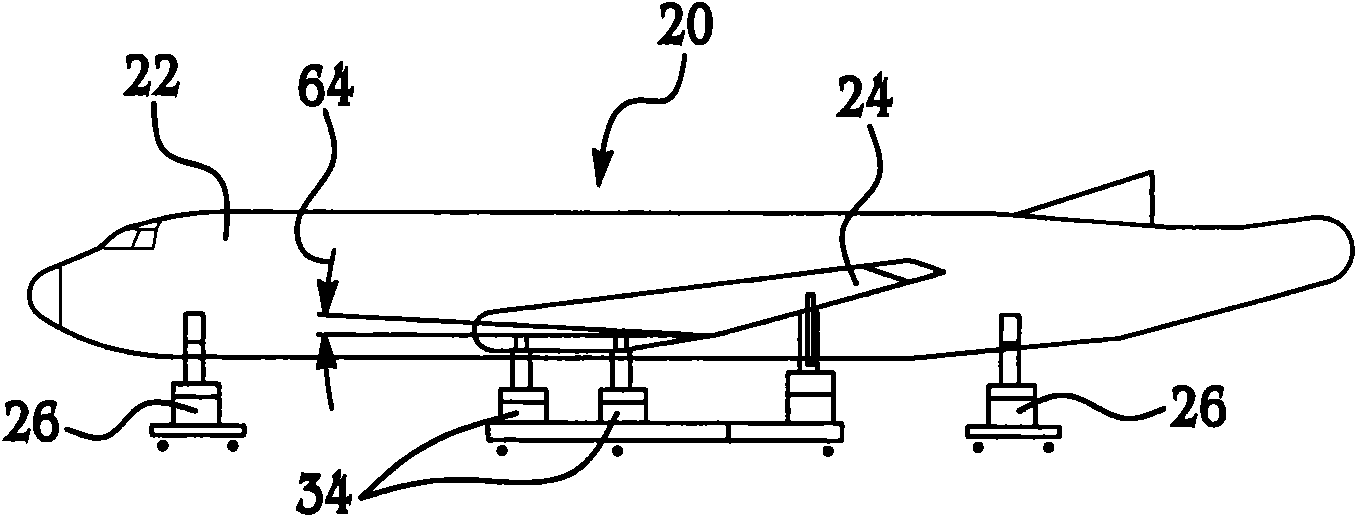

[0031] [0031] first reference Figure 1-Figure 3, embodiments of the present disclosure relate to methods and manufacturing processes for assembling and attaching parts or parts assemblies. As used herein, the terms "part" or "assembly of parts" are intended to include numerous structures and components to be assembled and / or joined together, and may also include individual parts, assemblies of parts or accessories. The method is particularly useful in the assembly of relatively large and complex parts or assemblies of parts where there are gaps or spaces between the parts being assembled that need to be filled with shims. In the illustrated embodiment, the parts comprise large assemblies used to build aircraft, however, it should be understood that the present methods and processes may be used and adapted for a variety of other types of part assemblies for a wide variety of applications.

[0032] [0032] Commercial aircraft 20 are typically manufactured by assembling large, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com