Polishing apparatus

A technology of equipment and polishing liquid, which is used in grinding/polishing equipment, metal processing equipment, machine tools for surface polishing, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

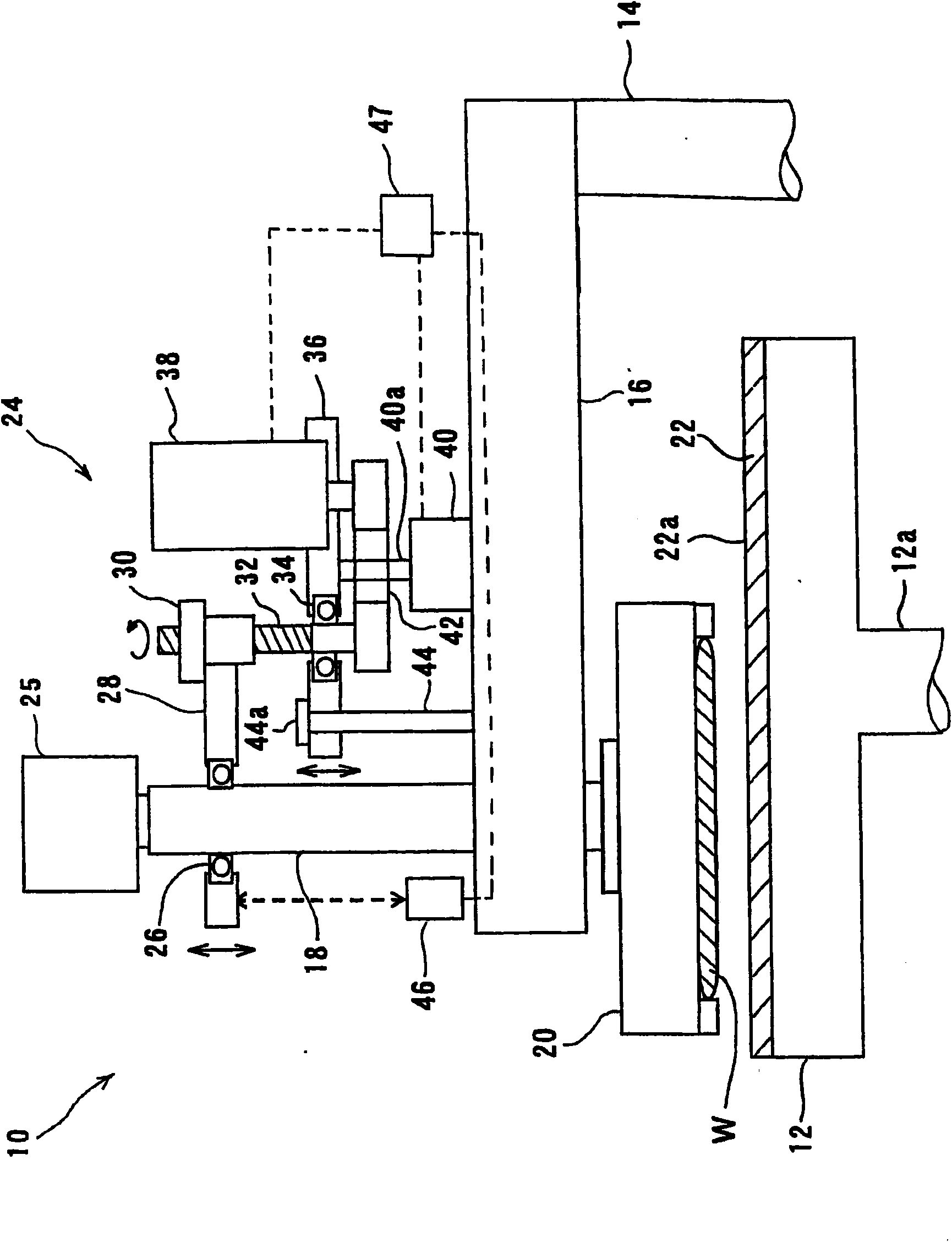

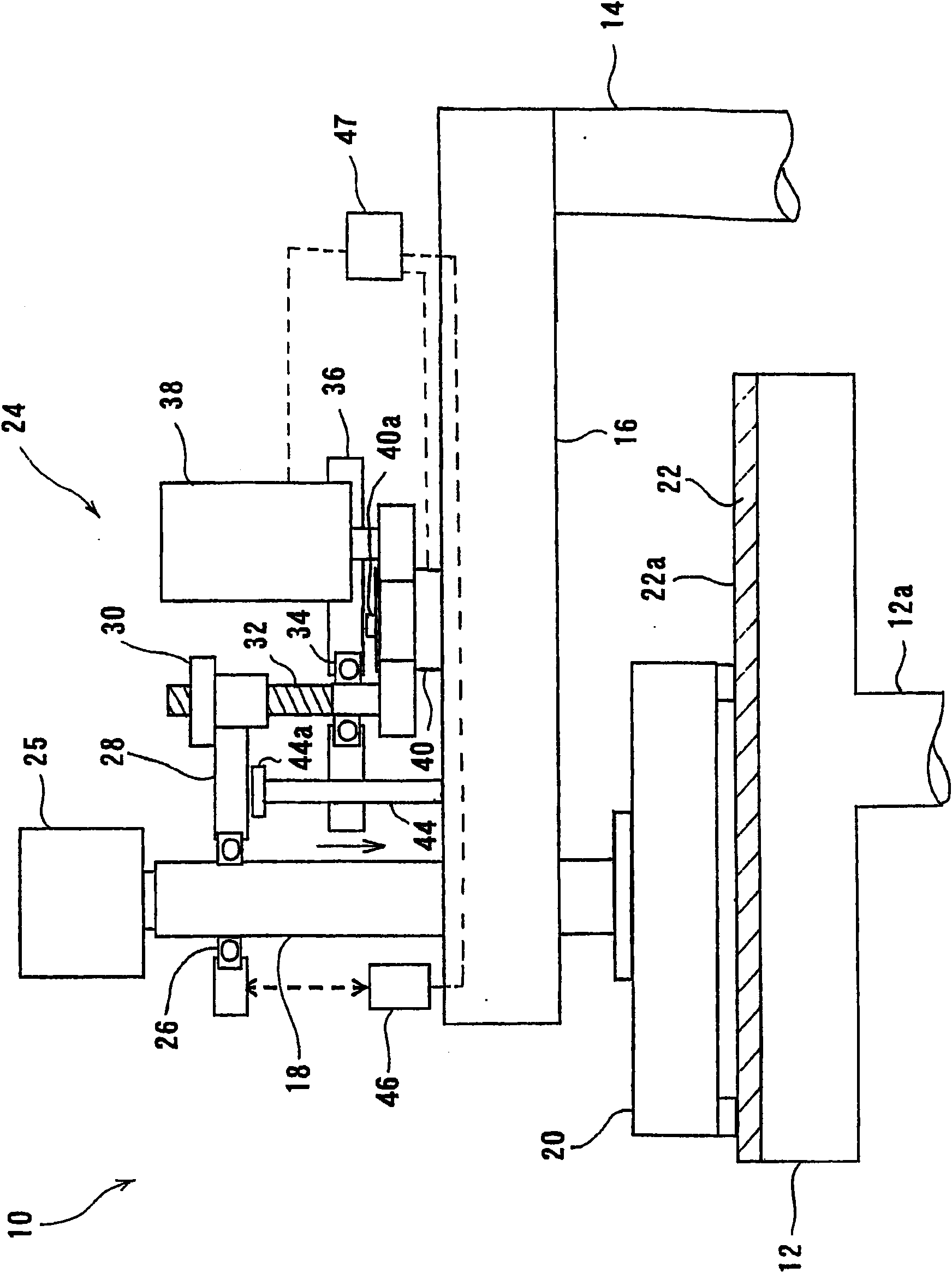

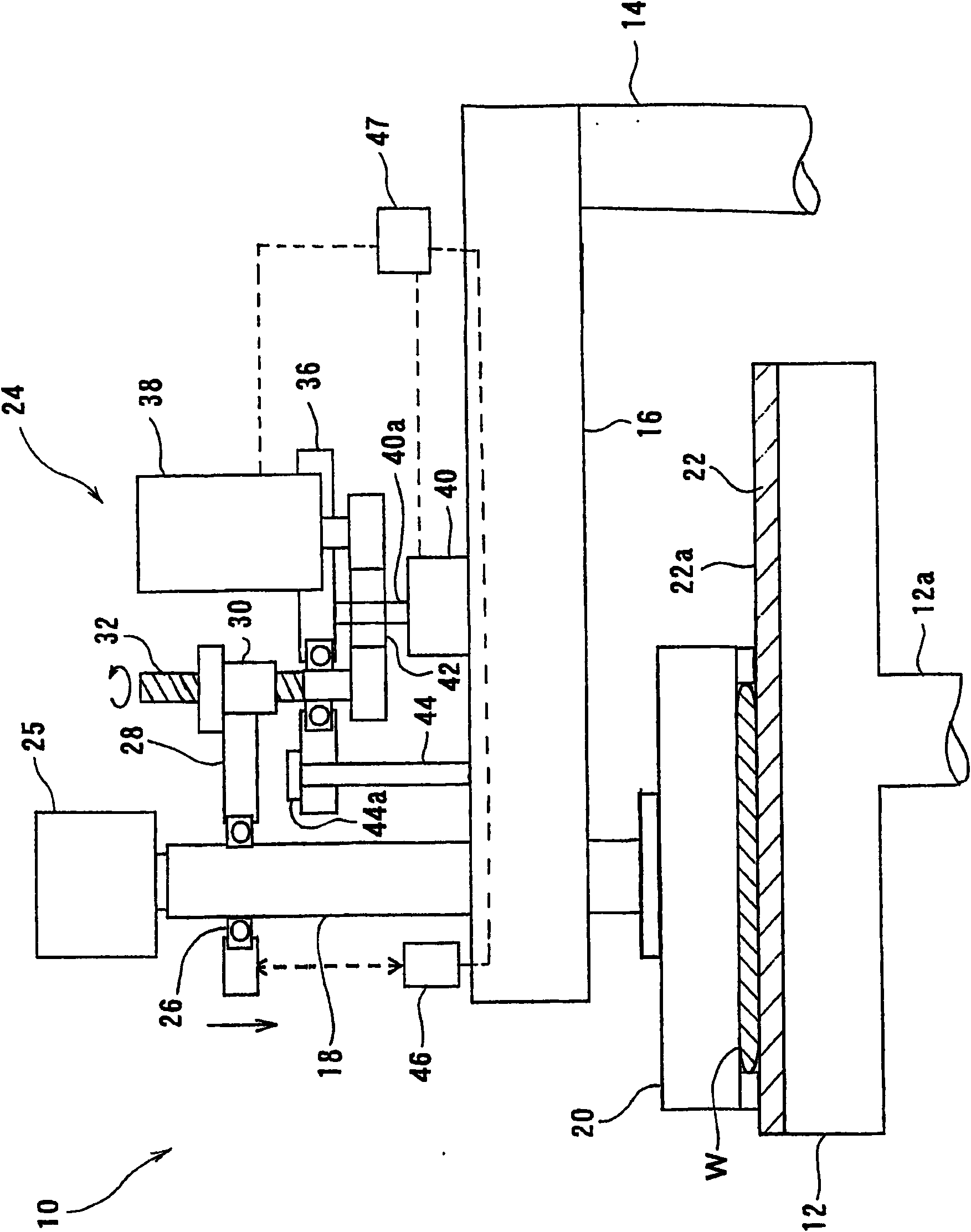

[0074] The following will refer to Figure 1 to Figure 32 An embodiment of the polishing apparatus according to the present invention is described. Like or corresponding parts are indicated with like or corresponding reference numerals throughout the drawings and will not be repeated below.

[0075] figure 1 is a schematic diagram showing a polishing apparatus 10 according to a first embodiment of the present invention. like figure 1 As shown, polishing apparatus 10 has polishing table 12 , top ring head 16 connected to the upper end of support shaft 14 , top ring shaft 18 mounted on the free end of top ring head 16 , and top ring 20 connected to the lower end of top ring shaft 18 . In the example shown, the top ring 20 is substantially in the form of a circular plate.

[0076] The polishing table 12 is connected to a motor (not shown) placed below the polishing table 12 via a table shaft 12a. Therefore, the polishing table 12 can rotate around the table axis 12a. like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com