Notch impact resistant polyaryletherketone molding composition

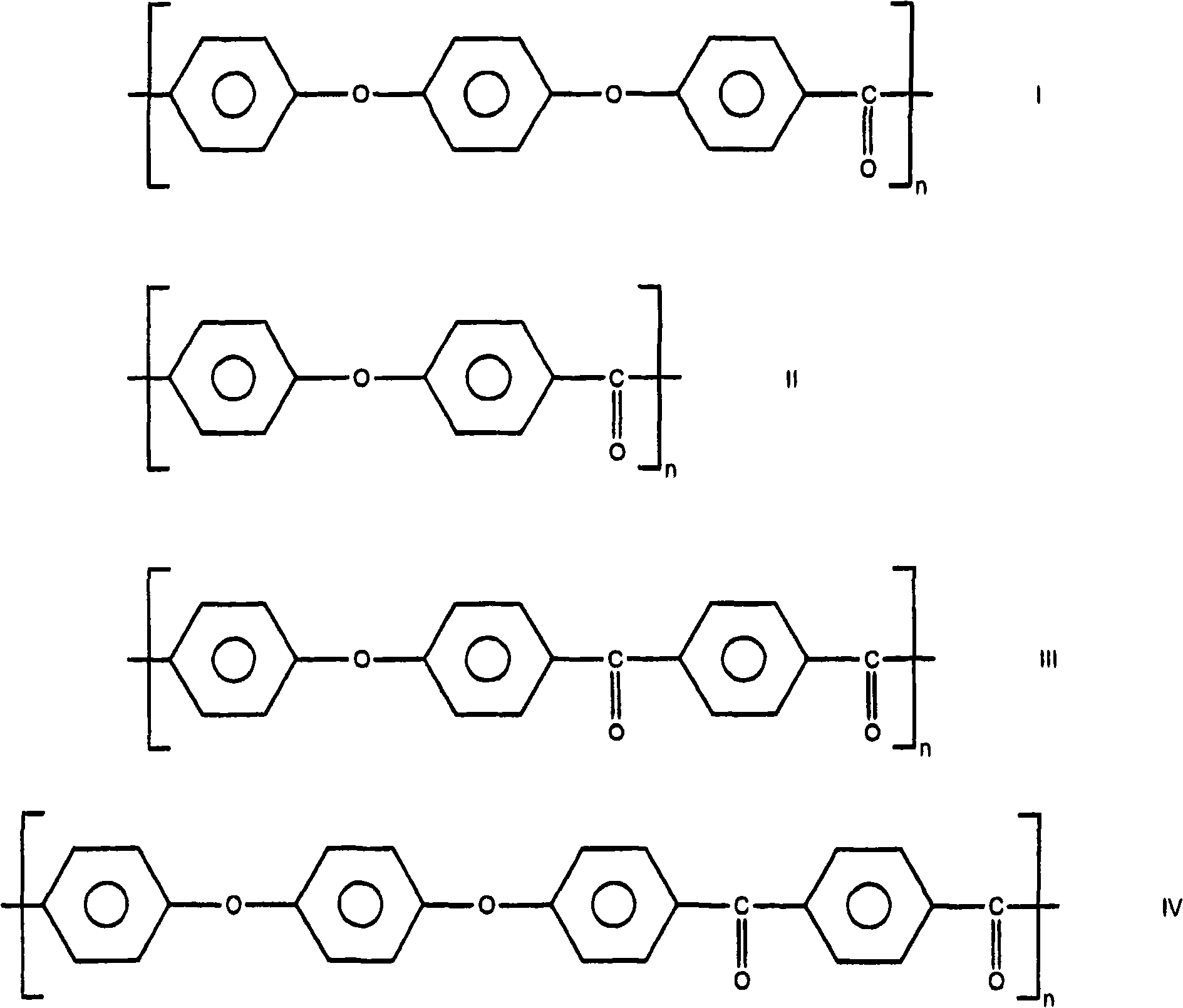

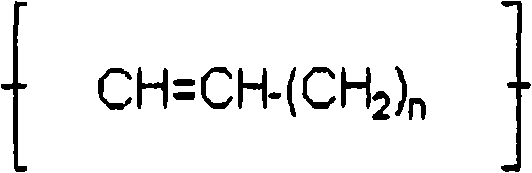

一种聚亚芳基醚酮、聚亚烯基的技术,应用在成型物料领域,能够解决不利、聚亚芳基醚酮低冲击韧性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: 95% by weight PEEK; 5% by weight polyoctenylene

Embodiment 2

[0028] Example 2: 90% by weight PEEK; 10% by weight polyoctenylene

Embodiment 3

[0029] Example 3: 85% by weight PEEK; 15% by weight polyoctenylene

[0030] pure 4000G was used as reference.

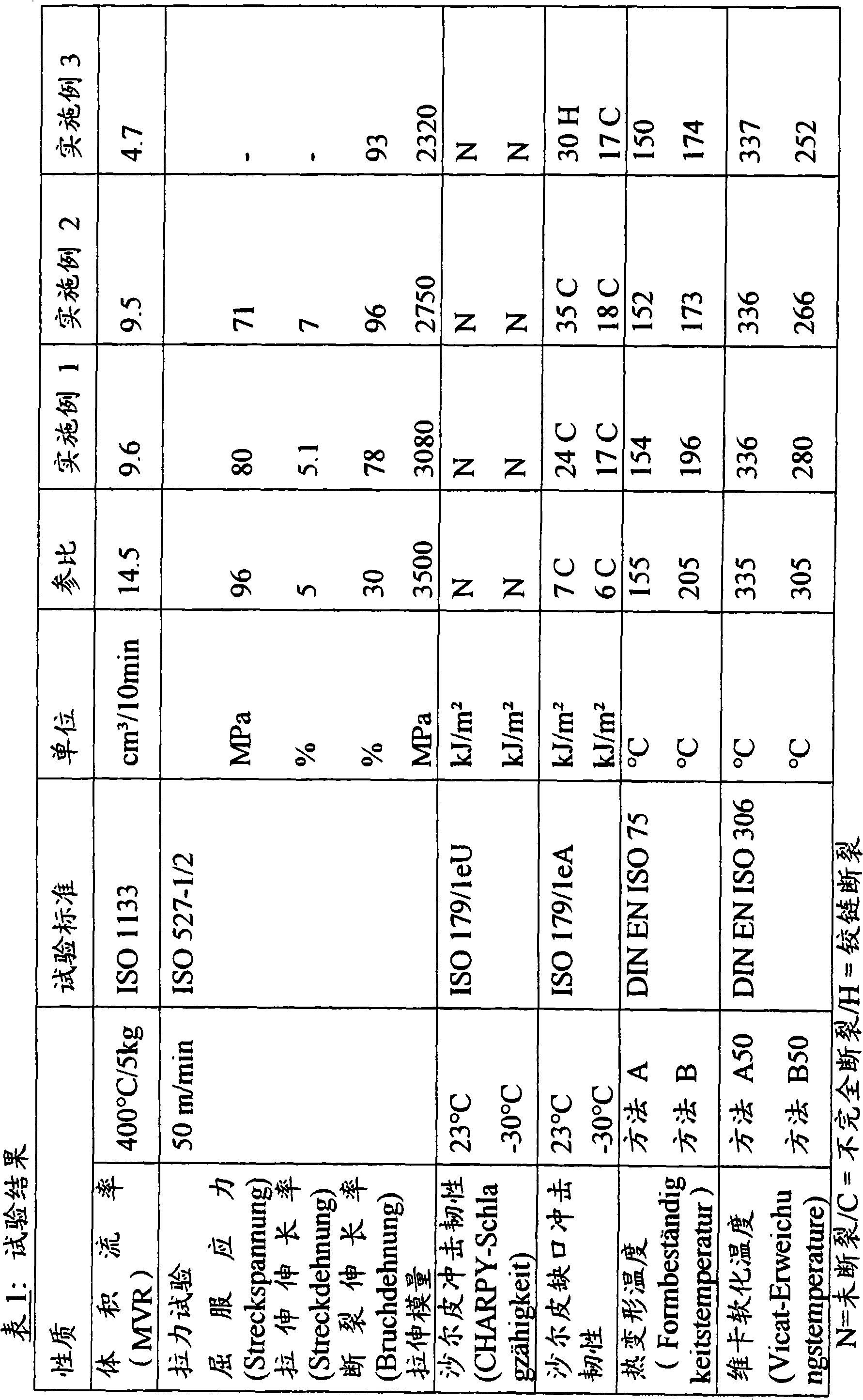

[0031] The granule composite and the reference material were processed in an Arburg injection molding machine at a material temperature of 380°C and a molding temperature of 180°C to prepare test specimens. The results of the mechanical and thermal tests are summarized in Table 1.

[0032]

[0033] The data show that, according to the invention, it is possible to significantly improve the notched impact toughness even at low octylene contents. Changes in the values of the other parameters were consistent with those expected when using rubber modifications. Surprisingly, despite the The limits stated in the product brochure for thermal stability (275°C in the case of the TGA test) are still understandable for this type of aliphatic compound, but even at the significantly higher At temperature (here 370° C.), the effect of the impact-modified rubber is also...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com