Improved structure of light board in light steel plant

A technology for lighting panels and workshops, which is applied to roofs, building structures, and roofs using flat/curved panels. It can solve the problems of easy water leakage at lap joints and condensation on lighting panels, so as to solve the hidden danger of water leakage and prevent condensation. , the effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

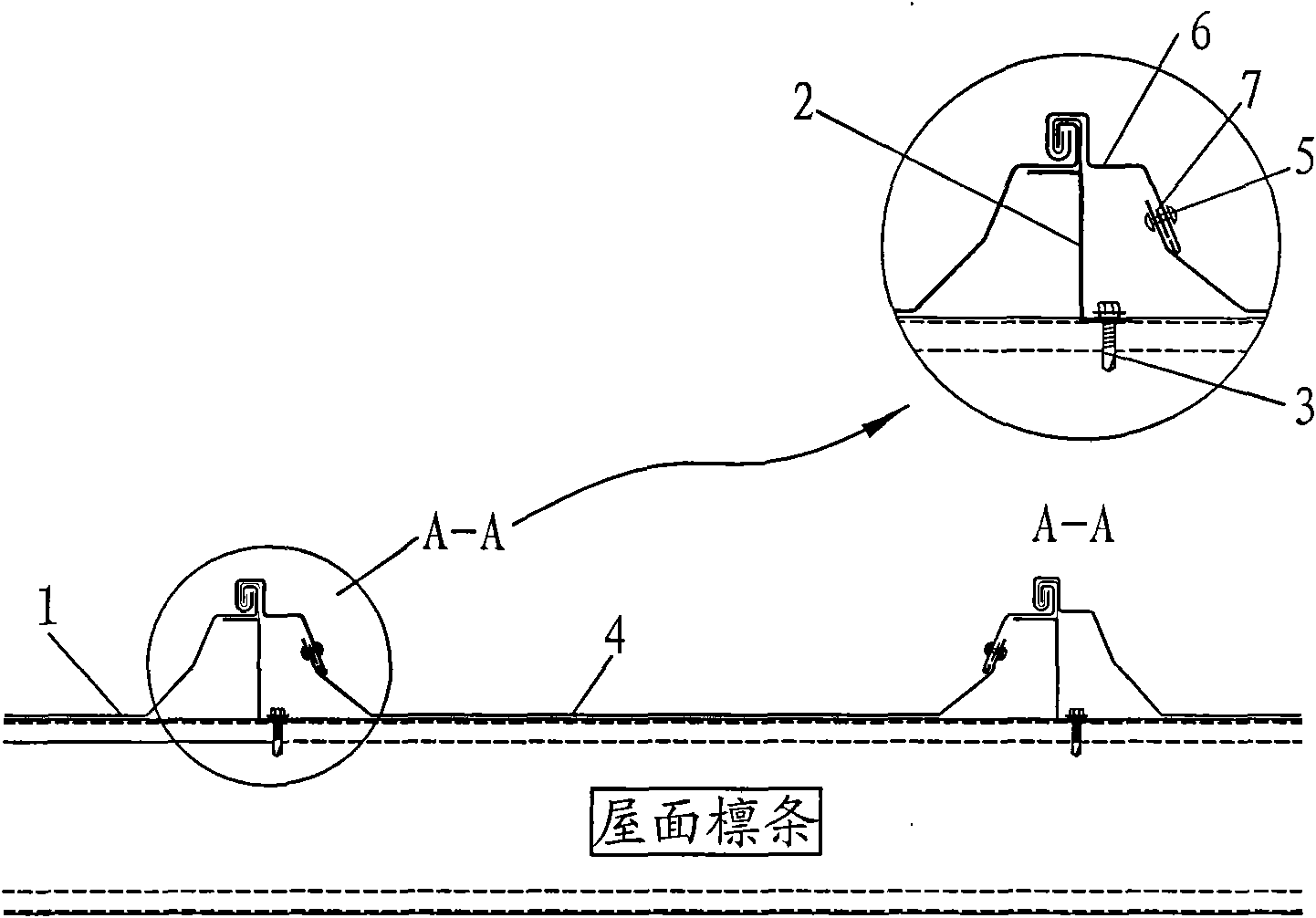

[0021] Embodiment 1: structure such as figure 2 As shown, the present invention includes a roof panel 1, a fixing seat 2 and a daylighting panel 4, the roof panel 1 is installed on the roof purlin through the fixing seat 2, the fixing seat 2 is fixed by self-tapping screws 3, and the roof panel is made of several boards. The seams of adjacent roof panels are located at the crests of the roof panels; the daylighting panels are one layer, located between the two seams of the roof panels, and the two ends of the lighting panels are connected to one side of the roof panel crests through connectors , Butyl tape is also added in the middle of the connection.

[0022] Connectors can be waterproof pull studs 5 or rivets or bolts.

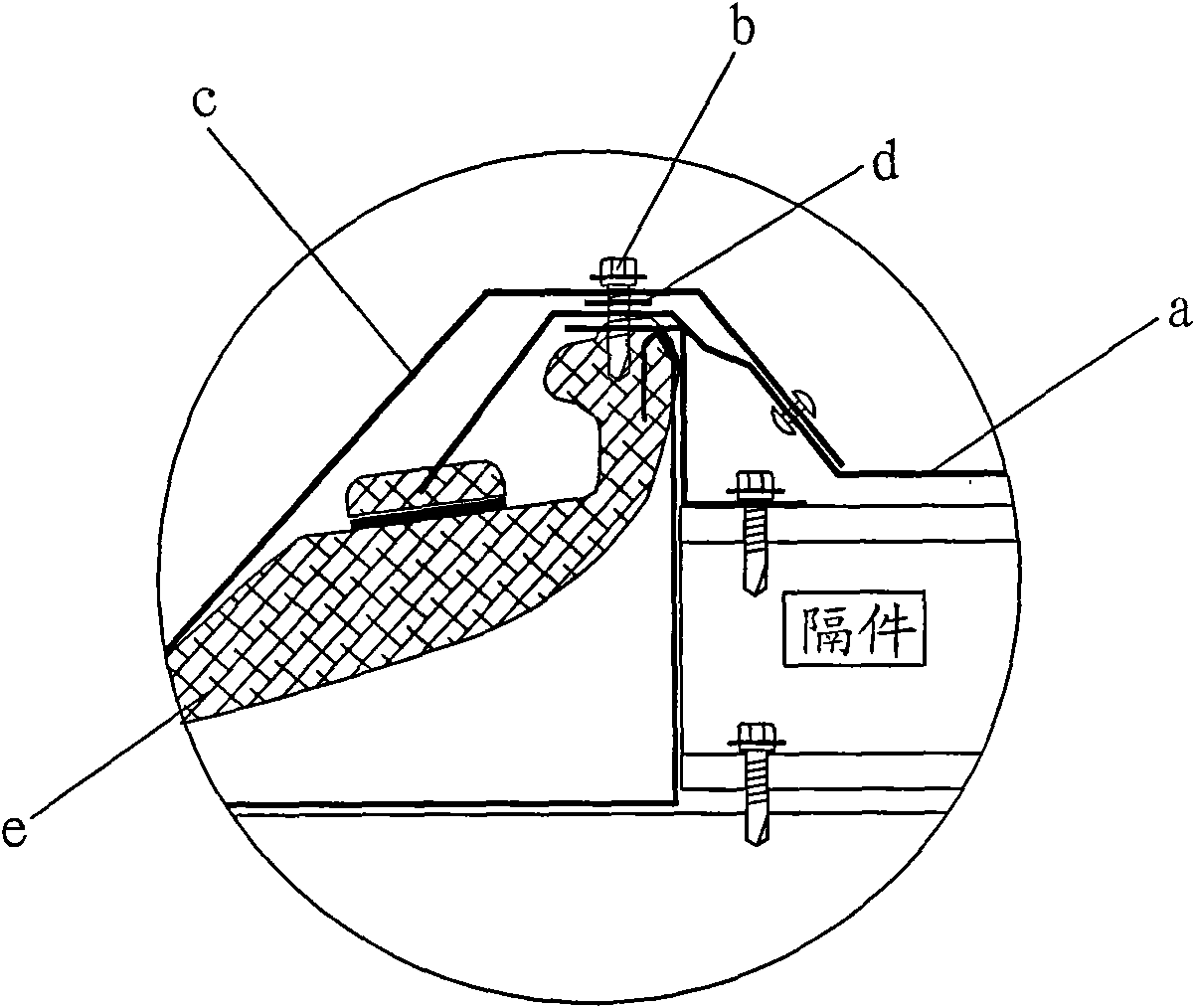

[0023] The 360-degree standing seam method is adopted at the overlapping joints of the roof panels, so that one of the roof panels is overlapped with the other steel plate edge 5, and the steel plate edge is connected with the daylighting panel. The edge...

Embodiment 2

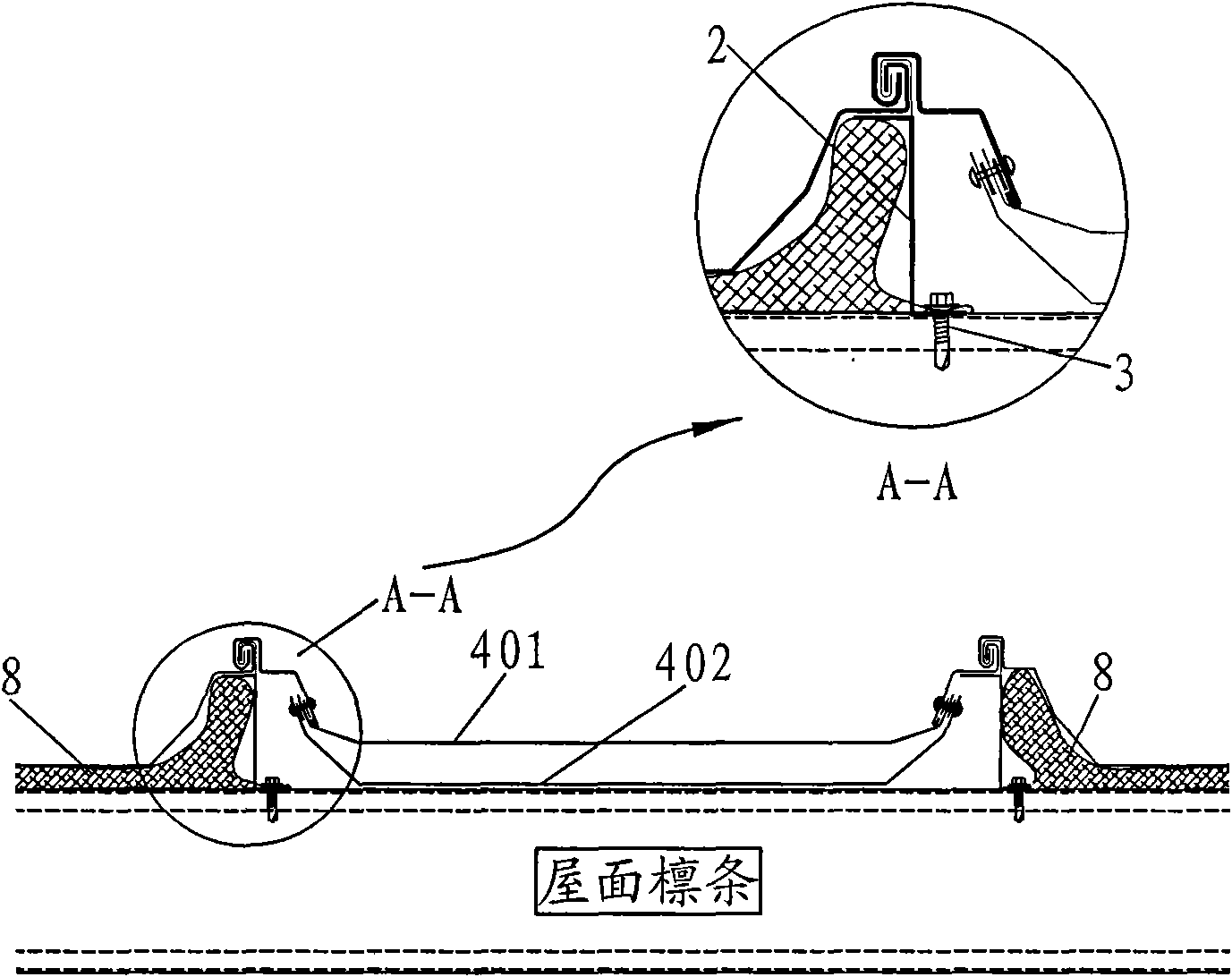

[0025] Embodiment 2: as image 3 , the daylighting board has two layers, namely the upper daylighting board and the lower daylighting board, the gap between the air layer in the middle is 20-30mm, and the surroundings of the two daylighting boards are sealed by PE foam plugs and butyl tape 7, so that the middle air layer is airtight and achieves heat preservation. Purpose. The bottom of some layer panels is provided with thermal insulation cotton 8, and others are the same as embodiment 1.

[0026] The anti-condensation design of the daylighting board of the present invention is to use a two-in-one double-layer daylighting board, that is, to connect and fix the two-layer daylighting boards into a whole in the factory, and leave an air layer with a gap of 20-30mm between the two layers of daylighting boards and set The butyl tape is sealed to ensure that the hollow is airtight. Due to the use of double-layer lighting panels and the existence of an intermediate air layer, the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap