Novel flexible thin-film battery and manufacturing method thereof

A flexible thin film and thin film battery technology, applied in primary batteries, electrodes of primary batteries, battery electrodes, etc., can solve the problems of thick thickness of flexible thin film batteries, low conductivity of current collectors, poor current collecting effect, etc., and achieve good conductivity. , high capacity, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

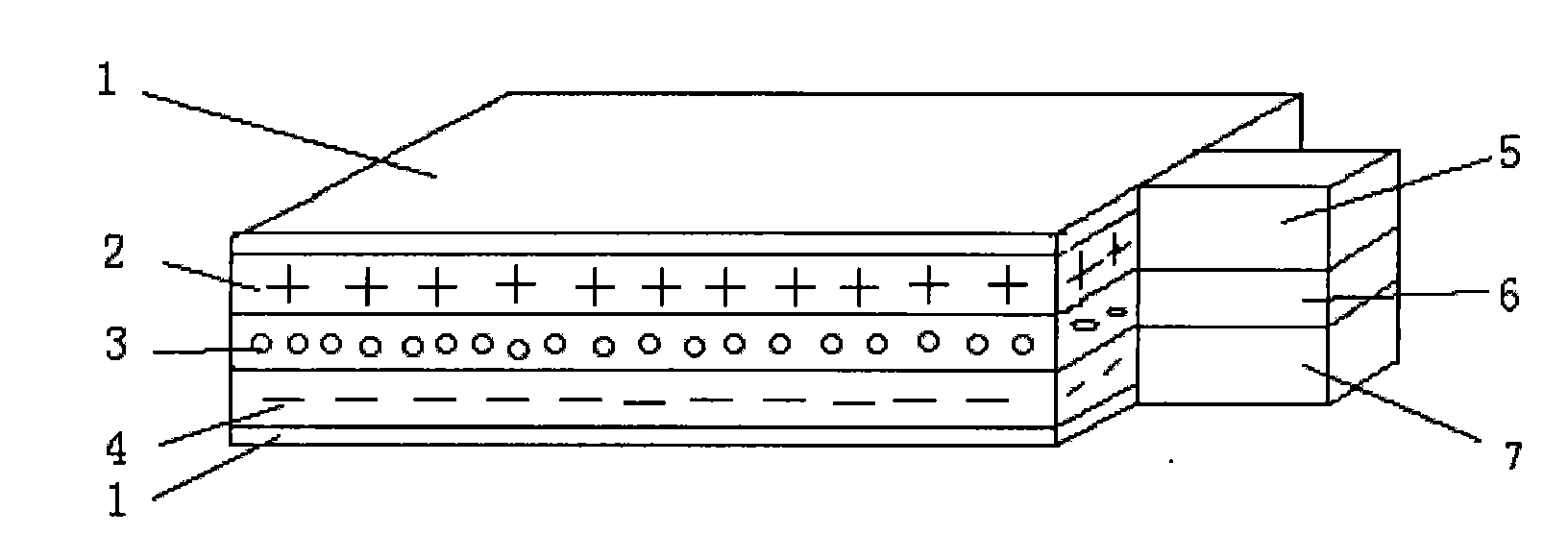

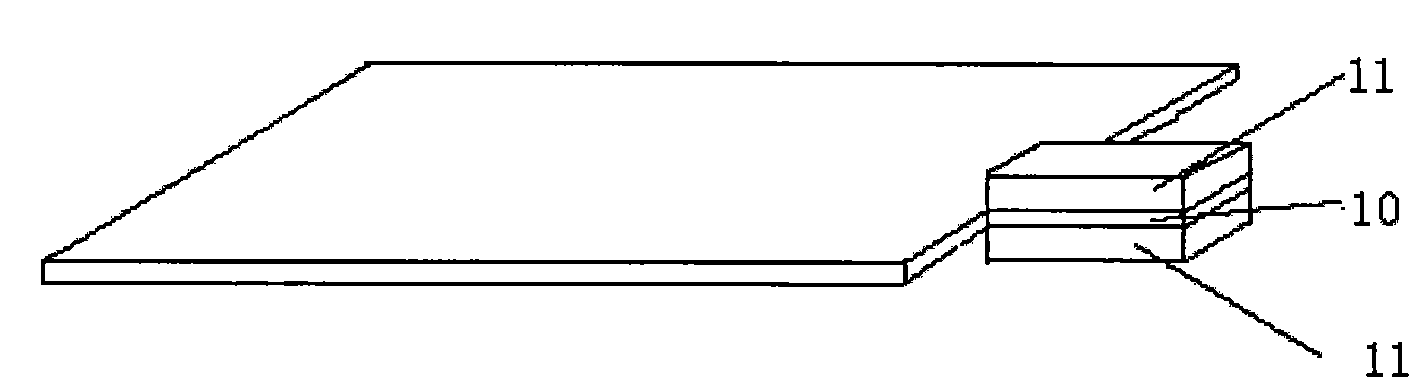

[0032] The lead wire given in this embodiment is a protruding flexible thin film battery structure. The longitudinal section is as follows: figure 1 shown. figure 2 , image 3 , Figure 4 Schematic diagrams of the structures of each part of this embodiment are given respectively.

[0033] exist figure 1 , figure 2The first example, first, with 40% NH 4 Cl solution added ZnCl 2 Prepare an electrolyte solution, and then immerse the special multifunctional polymer film in the electrolyte solution for 30 minutes to make a wet electrolyte isolation layer.

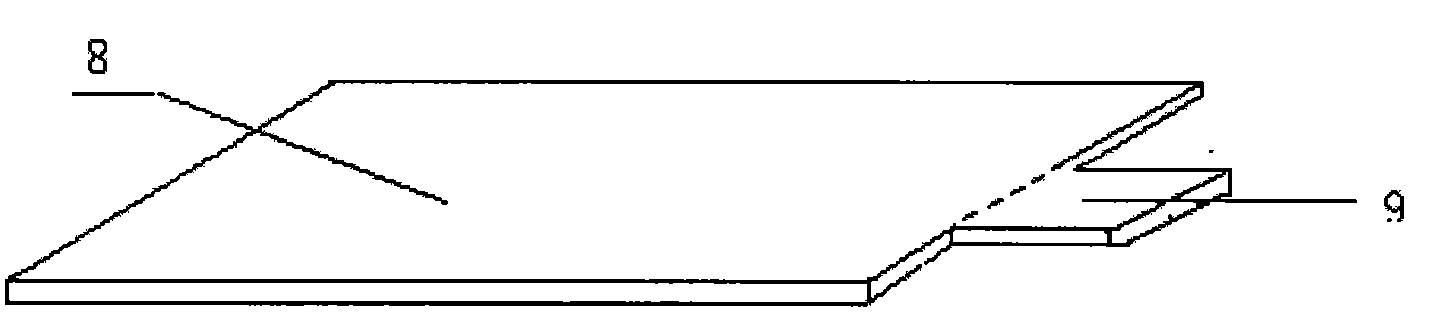

[0034] then press figure 2 Shape Cut the composite rubber conductive film with a thickness of about 0.08mm to obtain the current collector electrode film part 8 with a size of 40×50mm and the current collector lead part 9 protruding from one end of the current collector conductive film.

[0035] Plating a layer of zinc 12 on both sides of the current collector electrode film part 8 makes the thin film battery negative...

Embodiment 2

[0040] This embodiment provides a combined flexible thin film battery, the longitudinal section structure of the combined flexible thin film battery is as follows Figure 5 shown.

[0041] According to the manufacturing method of the above-mentioned embodiment 1, two groups of flexible thin-film batteries are obtained. The two batteries are directly stacked, and the lead part is made of conductive materials, so that the batteries can be connected in series or in parallel to obtain a combined flexible thin-film battery.

[0042] The combined flexible thin-film battery is externally connected to a load to test the voltage value. The test result: it drops from 3.15V to 2.3V at room temperature, and can maintain a current of 18μA / cm for 7 consecutive days. This method can form the series connection of the required multi-layer batteries, and can also realize the parallel connection of the batteries through the connection of the conductors.

[0043] It is found by the performance t...

Embodiment 3

[0046] This embodiment provides a flexible film battery with leads on the edge, and its structural longitudinal section is as follows Image 6 shown.

[0047] The materials and processing methods used in the insulating layer 13, the positive electrode layer 14, the electrolyte separation layer 15, and the negative electrode layer 16 in this embodiment are the same as in the first embodiment, the main difference is that the lead part of the battery is not protruding, but is located at the edge of the battery, and the lead part It includes a positive electrode lead layer 17 , an insulating layer 18 and a negative electrode lead layer 19 . The fabrication methods of the positive electrode lead layer 17 , the insulating layer 18 and the negative electrode lead layer 19 in this embodiment are the same as those in the first embodiment. The positive electrode layer 14, the electrolyte separator layer 15, the insulating layer 18 and the negative electrode layer 16 are laminated, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com