Die for extrusion molding of metal material

A metal material, extrusion molding technology, used in metal extrusion dies, metal extrusion molding tools, metal extrusion and other directions, can solve the problem of difficult to obtain a long enough mold life, cracking around the pressure part, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

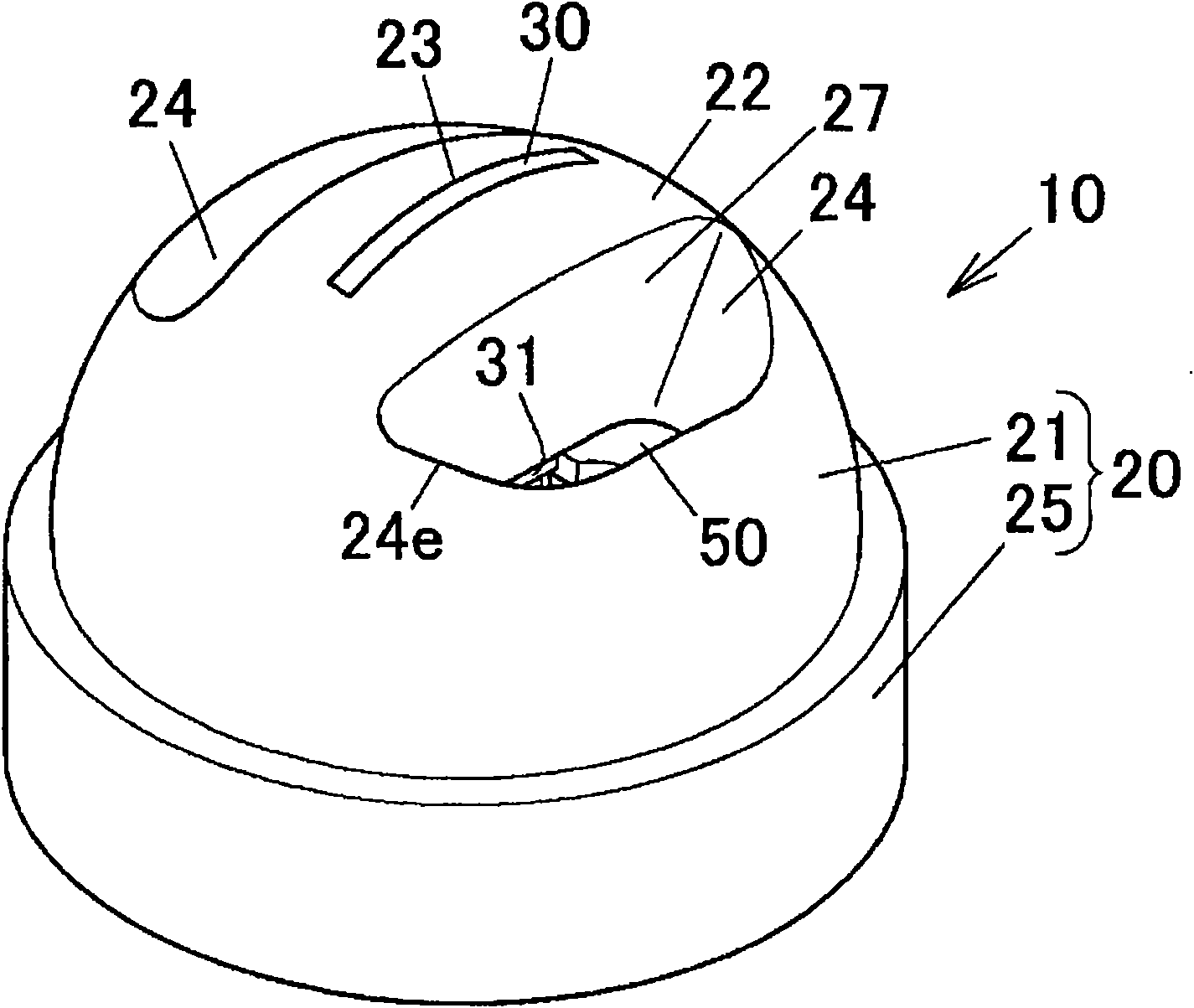

[0112] The metal material extrusion molding die 10 in the first embodiment of the invention is used for extrusion molding Figure 12 , 13 The mold for the porous hollow part 60 is shown.

[0113] The hollow member 60 is made of metal, and in this embodiment, specifically, constitutes a heat exchange tube made of aluminum or an aluminum alloy.

[0114] The hollow member 60 is used in a heat exchanger such as a condenser for an automobile air conditioner, and has a flat shape whose width is set larger than its thickness. The hollow portion 61 of the hollow body 60 is partitioned into a plurality of heat exchange passages 63 by a plurality of partition walls 62 extending in the tube length direction and arranged in parallel to each other. These passages 63 extend in the pipe length direction and are arranged in parallel to each other.

[0115] In addition, in this embodiment, the direction perpendicular to the length direction of the tube and parallel to the passage 63 is refe...

no. 2 Embodiment approach

[0159] Figures 14 to 17 It is a figure which shows the extrusion molding die in 2nd Embodiment of this invention. As shown in these figures, the extrusion molding die 10 of the second embodiment is a die for extrusion molding a pipe having an annular cross section, which is different from that of the first embodiment for extrusion molding a flat extruded pipe. The molding die 10 is different.

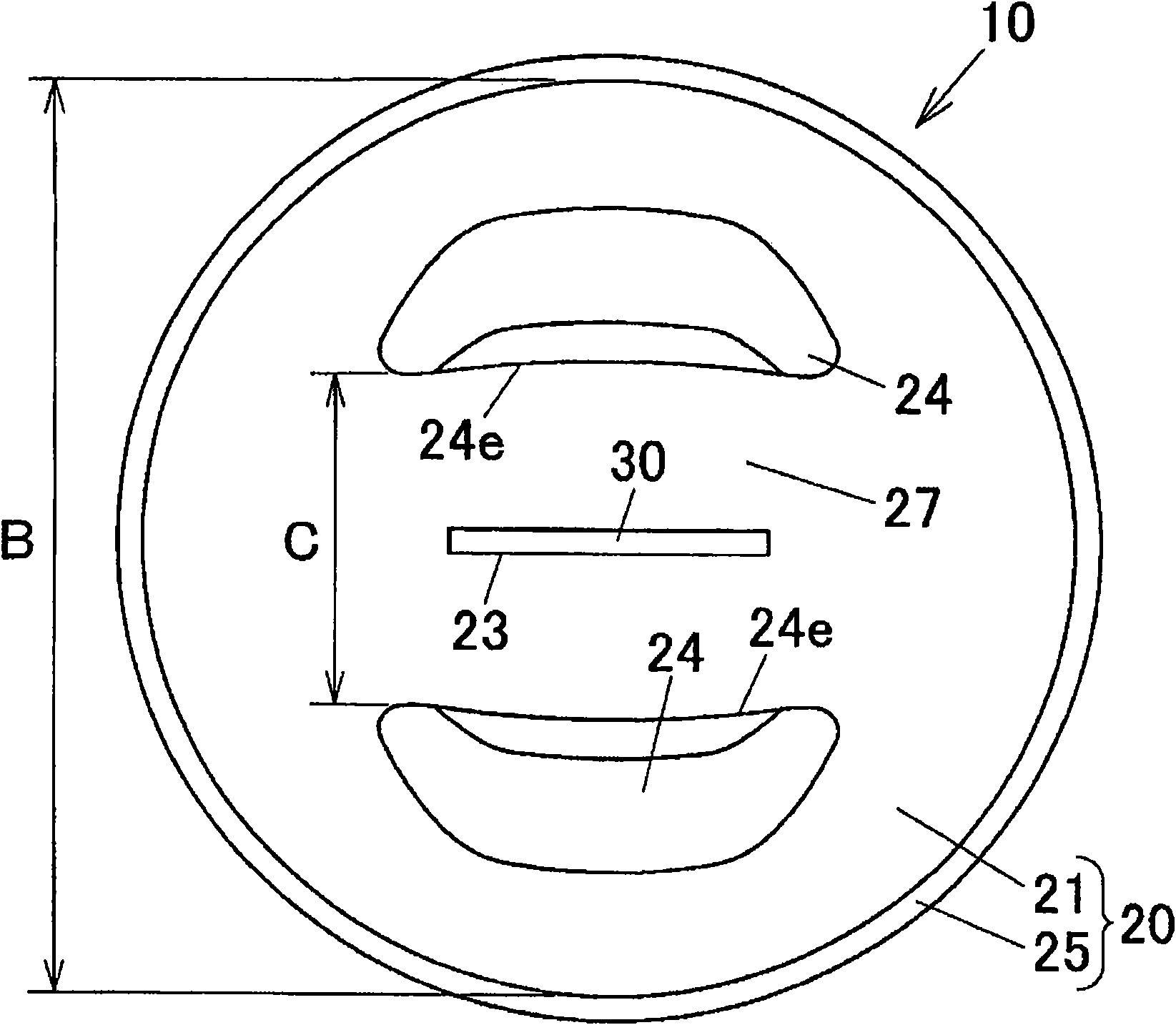

[0160] That is, three orifices 24 are respectively formed at equal intervals in the circumferential direction around the axis on the peripheral wall of the pressure receiving portion 21 of the die case 20 . Each orifice 24 is arranged so that the axis of the orifice 24 crosses the axis of the pressure receiving part 21 and is inclined so as to approach the axis of the pressure receiving part 20 toward the downstream side as described above. In addition, the optimum range of the inclination angle of the orifice axis with respect to the pressure receiving part axis is the same as above...

Embodiment 1-1

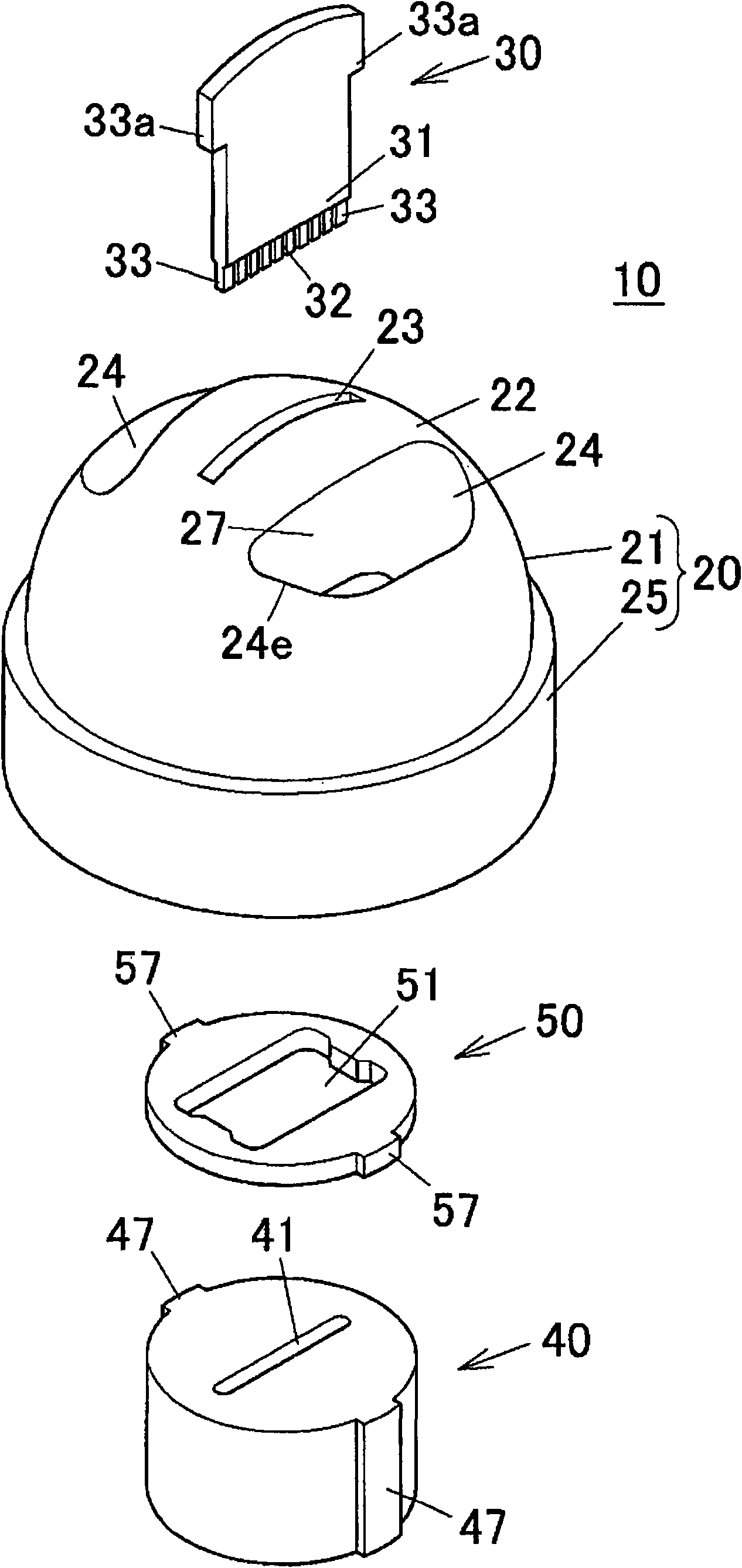

[0188] ready with Figure 1-8 The extrusion mold 10 corresponding to the first embodiment shown above is shown. The male die 30 of this mold 10 is adjusted so that the thickness of its mold core 31 is 2.0 mm, the width of the mold core 31 is 19.2 mm, the height of the passage forming convex part 33 is 1.2 mm, and the passage forming convex part 33 The width was 0.6 mm, and the width of the groove for forming the partition wall was 0.2 mm.

[0189] For the female mold 40, the height of the die hole 41 is adjusted to 1.7 mm, and the width of the die hole 41 is adjusted to 20.0 mm.

[0190] Two orifices 24 of the mold case 20 are correspondingly formed on both sides of the extrusion hole 11 in the thickness direction. The inclination angle θ of each orifice 24 is adjusted to 10°, that is, the inclination angle θ of the axis X2 of each orifice 24 with respect to the axis X1 of the mold cover 20 is adjusted to 10°, and, inside each orifice 24 The inner surface 24a and the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com