Coal slime rotational flow reselecting column

A technology of coal slime and cylinder, which is applied in the direction of swirl devices and devices whose axial direction of swirl can be reversed, etc., which can solve the problems of easy loss, easy wear and low separation accuracy of coarse-grained and low-density materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

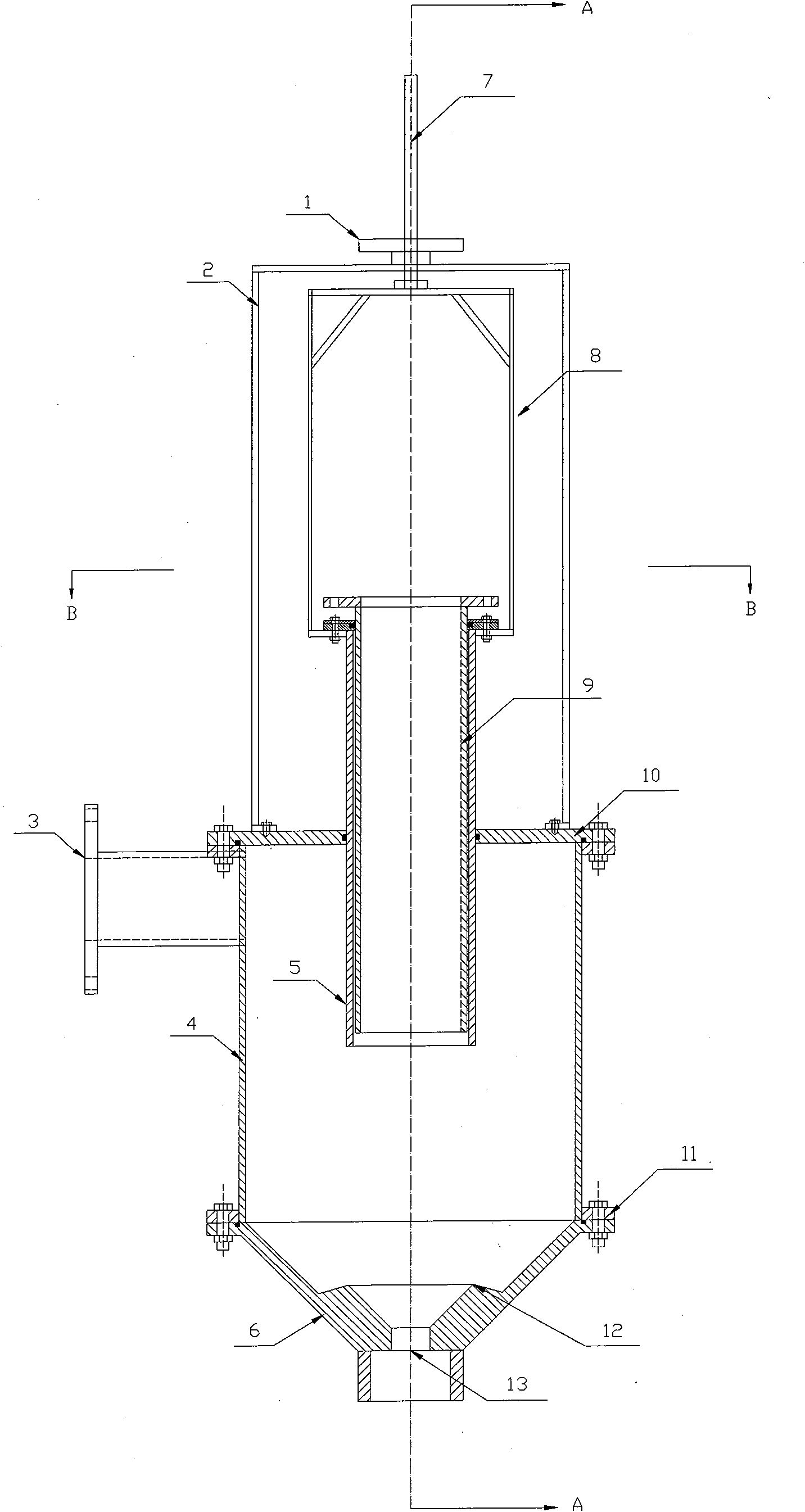

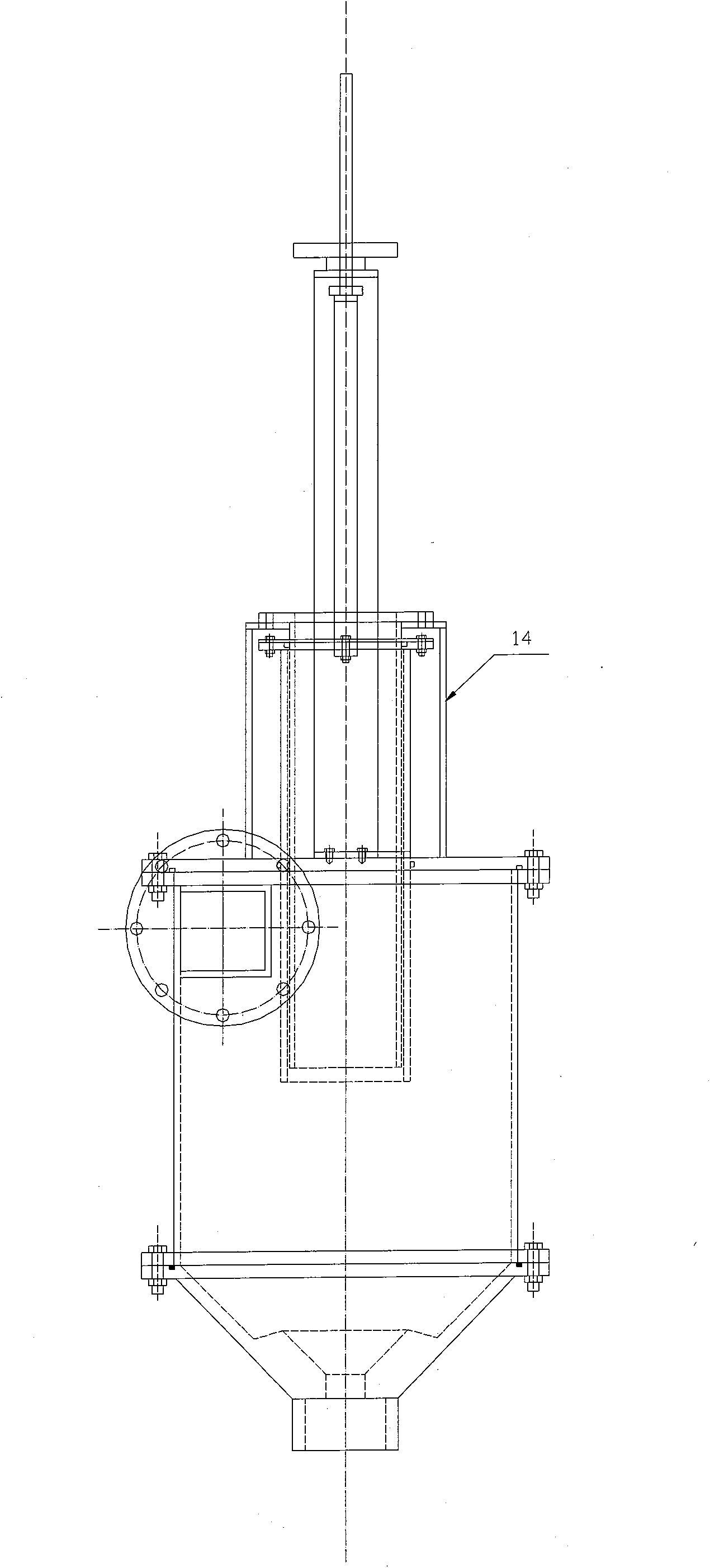

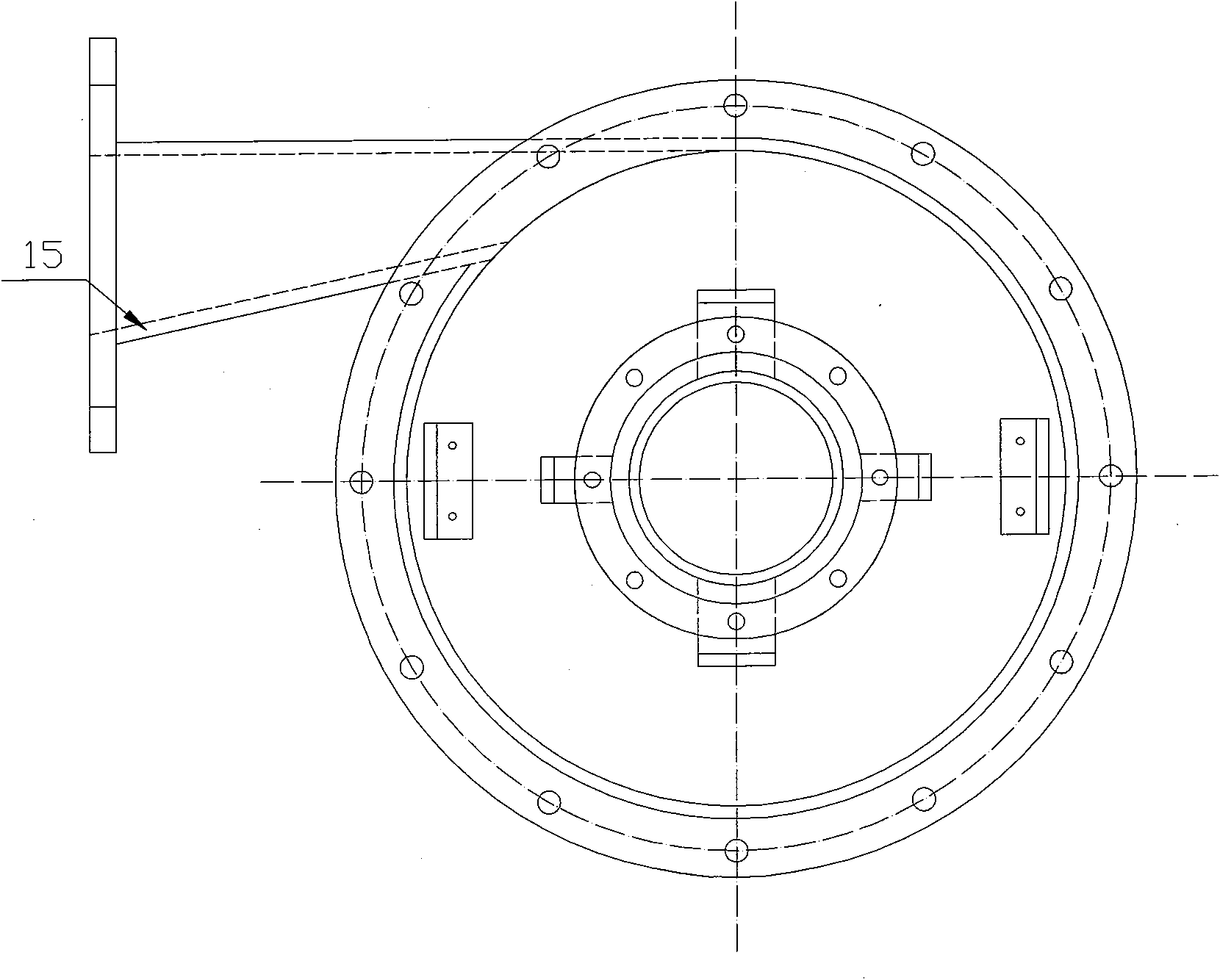

[0014] figure 1 The structure diagram of the coal slime cyclone gravity separation column of the present invention is given. The coal slime swirl gravity separation column of the present invention comprises a cylinder body 4, a feed pipe 3 arranged tangentially on the upper part of the cylinder body 4, an overflow pipe coaxially arranged inside the cylinder body 4 and the cylinder body 4, and the lower end of the cylinder body 4 passes through The connecting flange 11 is hermetically fixed to the cone 6 and other components, and a circular bottom flow opening 13 is opened at the center of the lower part of the cone 6 . The cone 6 at the lower end of the slime cyclone gravity separation column body 4 is set as a reverse double-cone hydraulic jump structure 12, and the cone 6 of the reverse double-cone hydraulic jump structure 12 is designed as a forward cone-reverse co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com