Soft-touch initial height floating adjustment system of bevel welding-cutting mechanical hand

A technology of initial height and robot hand, which is applied in the mechanical field, can solve problems such as current interference, easily damaged gun tip or sensor, and measurement deviation, so as to avoid correction and compensation, and prevent easy damage to the contact unit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

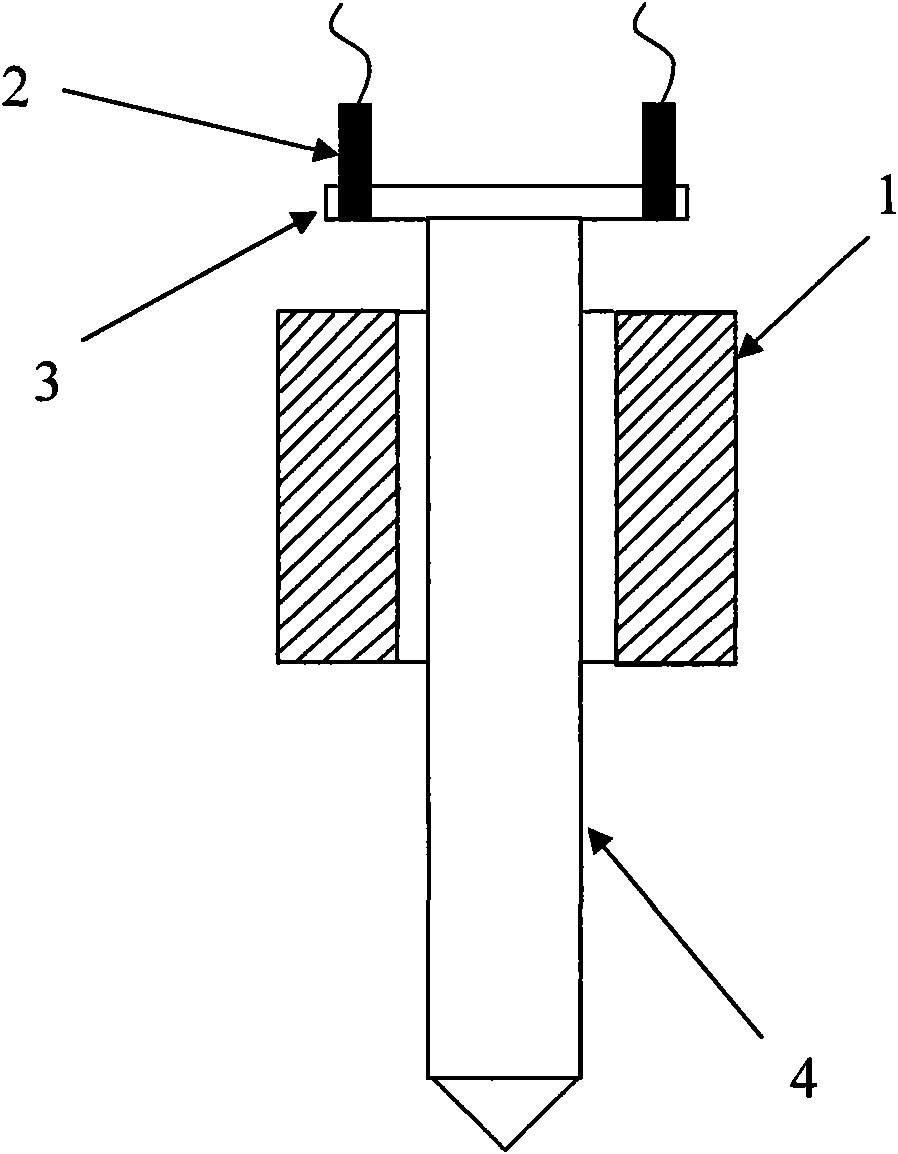

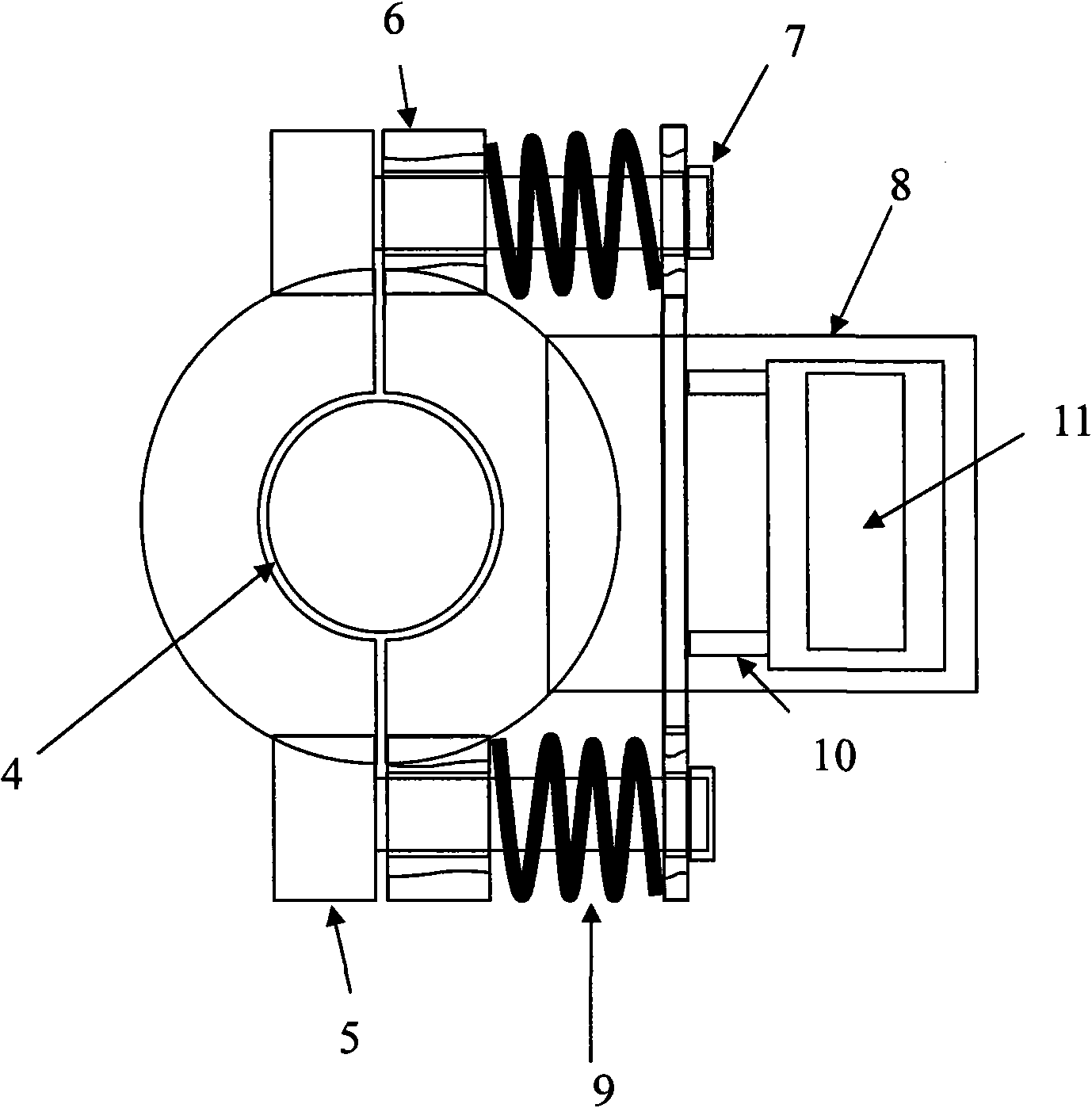

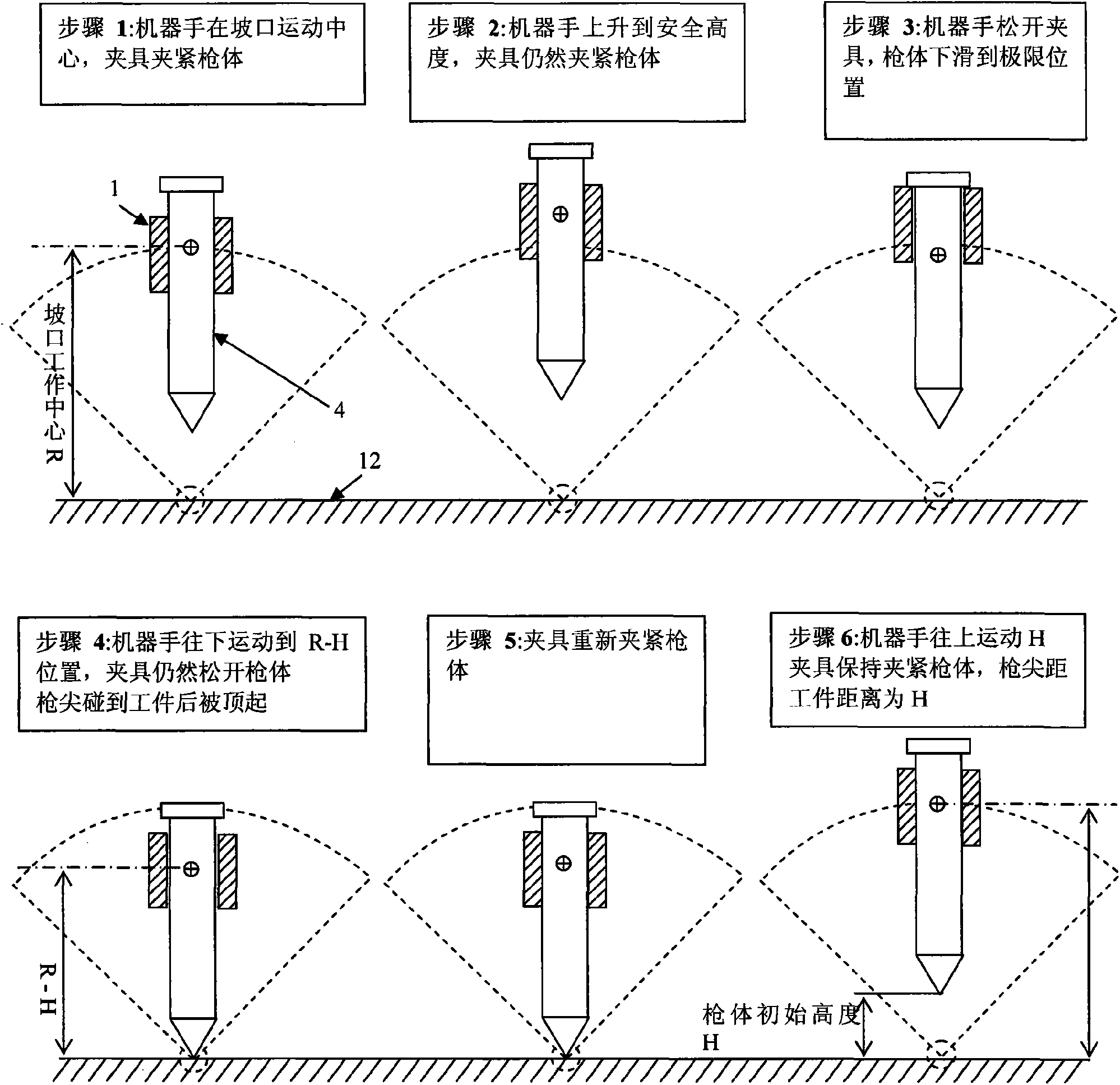

[0019] Such as figure 1 , figure 2 and image 3 As shown, the non-contact initial height floating adjustment system of the groove welding and cutting manipulator of the present invention consists of a gun body clamp 1, a group of sensors 2, a hard limiter 3 for the gun body sliding down and a controller (not shown in the figure) , the controller adopts the prior art, wherein the gun body fixture is composed of a first semicircle fixture piece 5 and a second semicircle fixture piece 6, and the first semicircle fixture piece 5 and the second semicircle fixture piece An opening and closing driving mechanism is arranged between the clamping pieces 6, and the opening and closing driving mechanism is composed of an electromagnetic micro-motion thruster 11 and a connecting rod connecting the first semicircular clamping piece or the second semicircular clamping piece. The micro thruster 11 is connected with the controller through a control line.

[0020] Further, when the gun body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com