Automatic air releasing device of vehicle inner tube

An automatic deflation, motor vehicle technology, applied in the direction of tire installation, vehicle parts, tire parts, etc., can solve the problem of high production cost of inner tube, and achieve the effect of reducing scrap rate and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

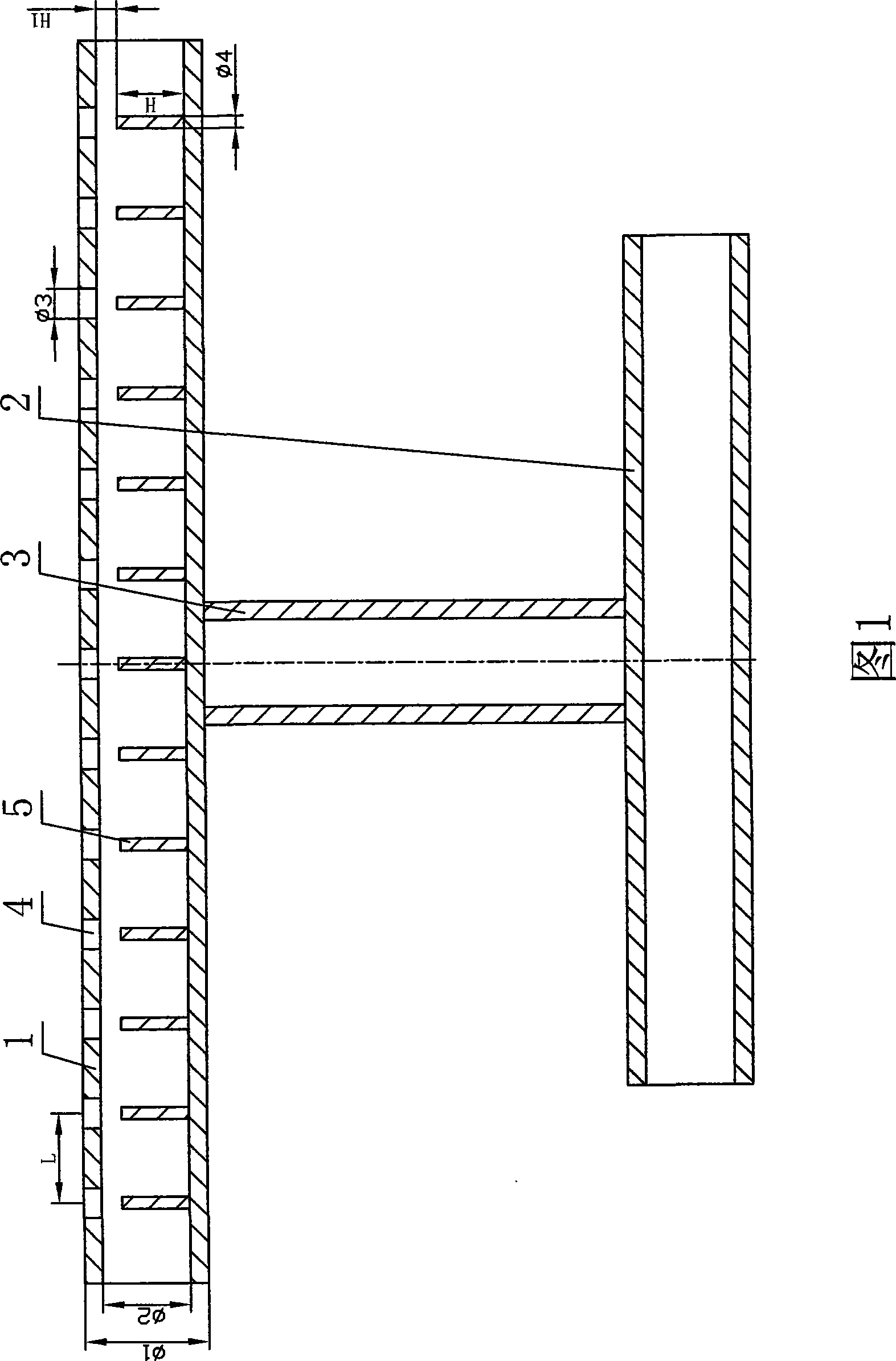

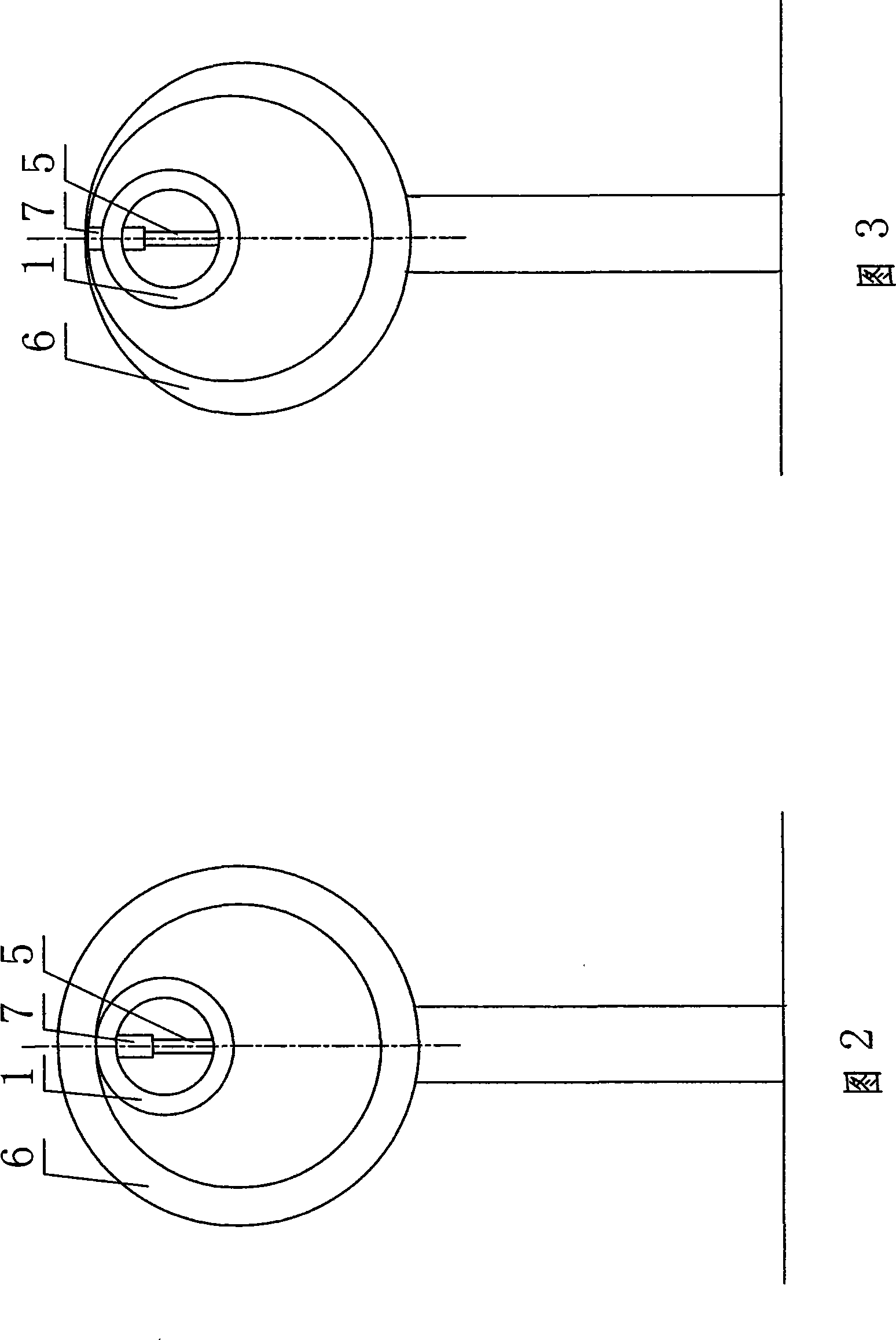

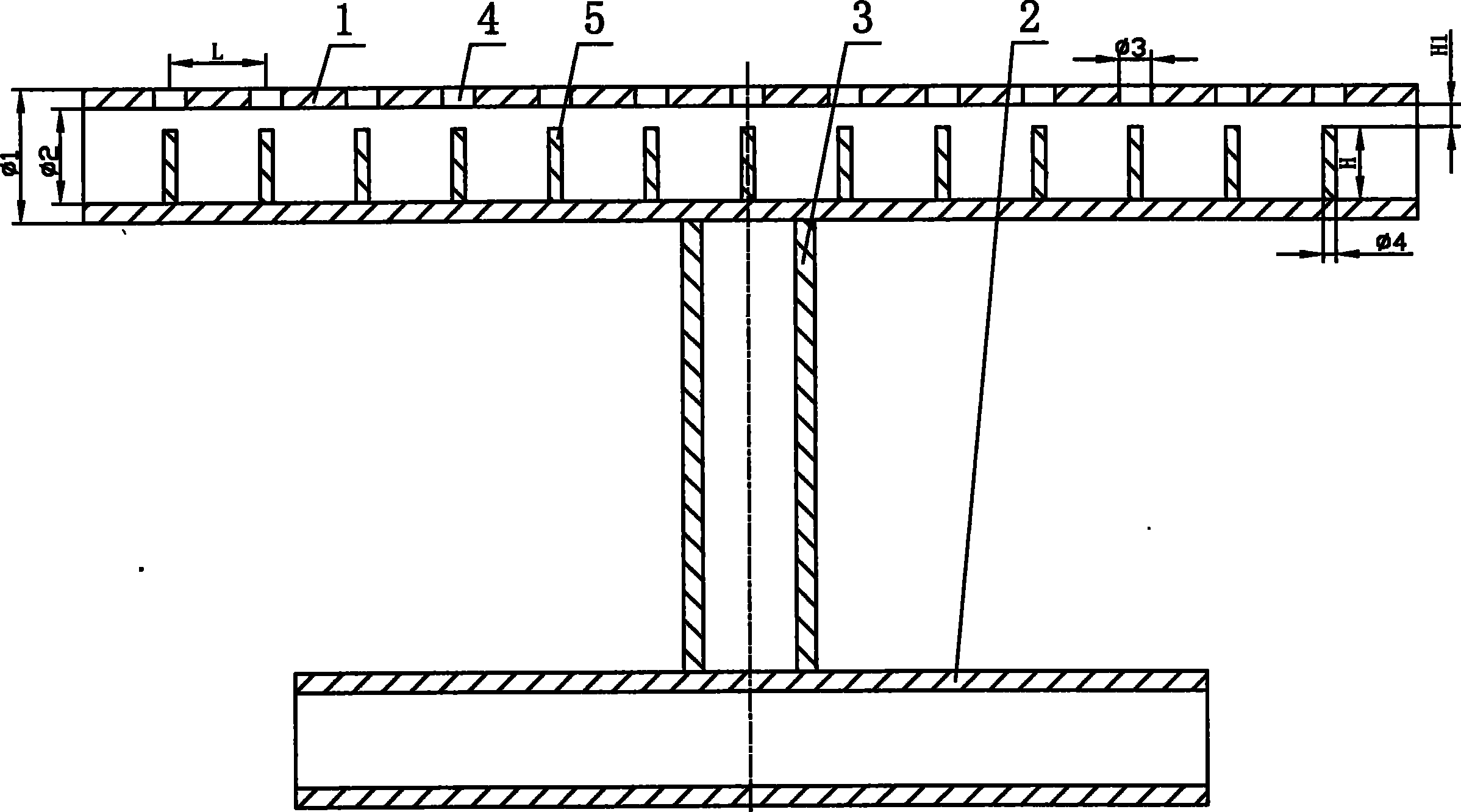

[0016] 1, the automatic deflation device of the inner tube of the present invention includes a bracket and a horizontal tube 1 fixed to the upper end of the bracket. The bracket includes a base 2 and a support rod 3 perpendicular to the base. The lower end of the support rod is welded and fixed to the base. The base in this embodiment adopts a cross-shaped base welded by steel pipes. Of course, the bracket can also be a triangular bracket or the like. The top of the stent is welded and fixed to the middle of the wall of the horizontal tube 1. The axial direction of the horizontal tube 1 is parallel to the horizontal plane. The outer tube diameter is 48mm, the inner tube diameter is 42mm, and the tube wall thickness is 3mm. The wall of the horizontal tube 1 is evenly spaced with a number of through holes 4 arranged along the axis of the horizontal tube for the valve of the inner tube to pass through. The number of through holes on the horizontal tube is 10-20. In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com