Anti-icing and deicing method for civil aircraft adopting loop heat pipes

A loop heat pipe and anti-icing technology, which is applied in the direction of deicing devices, aircraft parts, indirect heat exchangers, etc., can solve the problems of reducing aircraft flight performance, low heat utilization rate, and reduced available engine thrust, so as to increase heat Utilization rate, effect of improving flight performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] Embodiment: When the anti-icing and de-icing component of civil aircraft is the leading edge of the engine inlet:

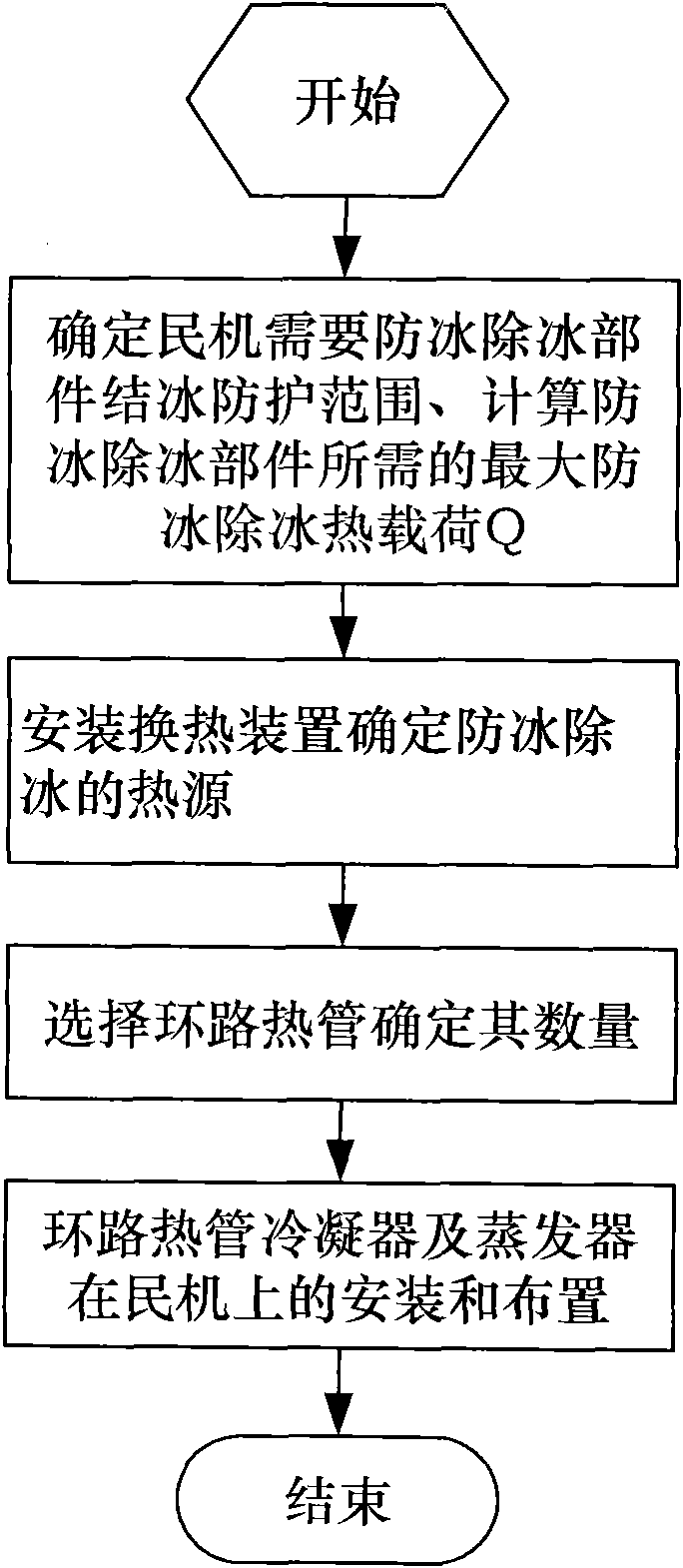

[0055] The present invention specifically comprises the following steps:

[0056] Step 1: Determine the icing protection range and the required thermal load Q of the leading edge of the civil aircraft engine intake under the most severe icing conditions;

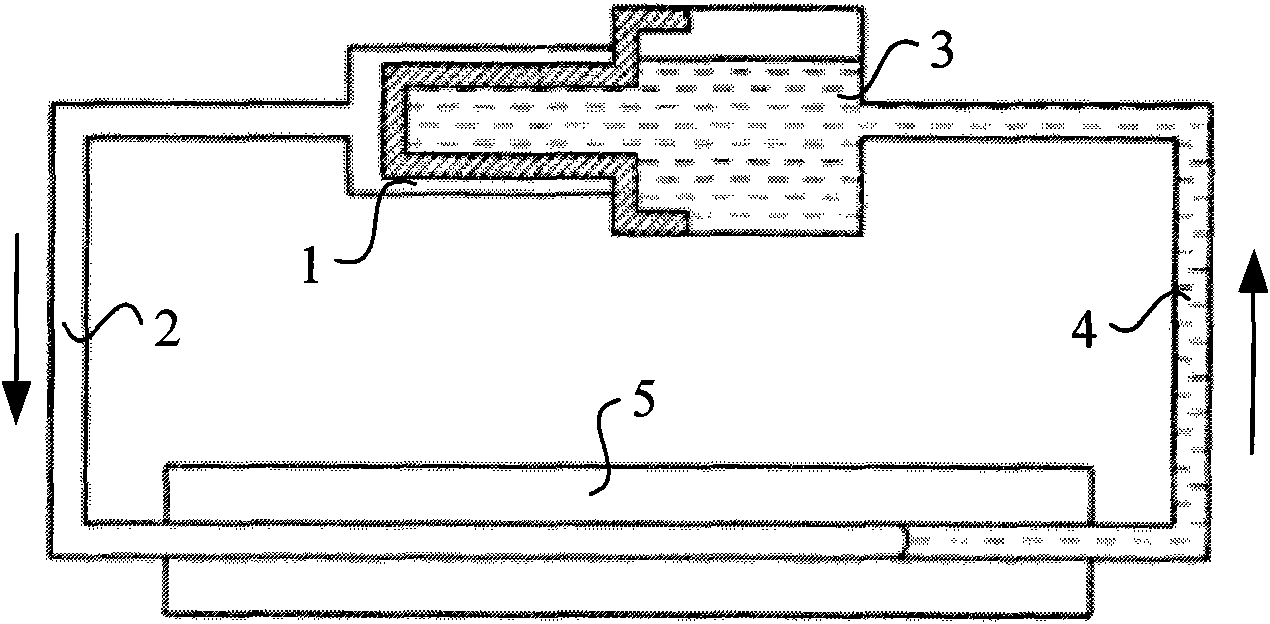

[0057] Step 2: Install the heat exchange device to determine the heat source for anti-icing and deicing;

[0058] The heat source for anti-icing at the leading edge of the engine intake is the high-temperature engine bleed air sent to the air-conditioning system, so the heat exchange device should be installed before the bleed air reaches the air-conditioning system. It can be considered to install the heat exchange device in the engine nacelle, or it can be It is installed in the fuselage. The specific installation location is mainly affected by the development and manufacturing level of the loop heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com