Charging nozzle of inflation pump

A pump and inflator technology, applied in vehicle maintenance, functional valve types, control valves, etc., can solve the problems of large air intake, impracticality, inability to provide air nozzles, etc., to achieve smooth air intake and small structure and volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

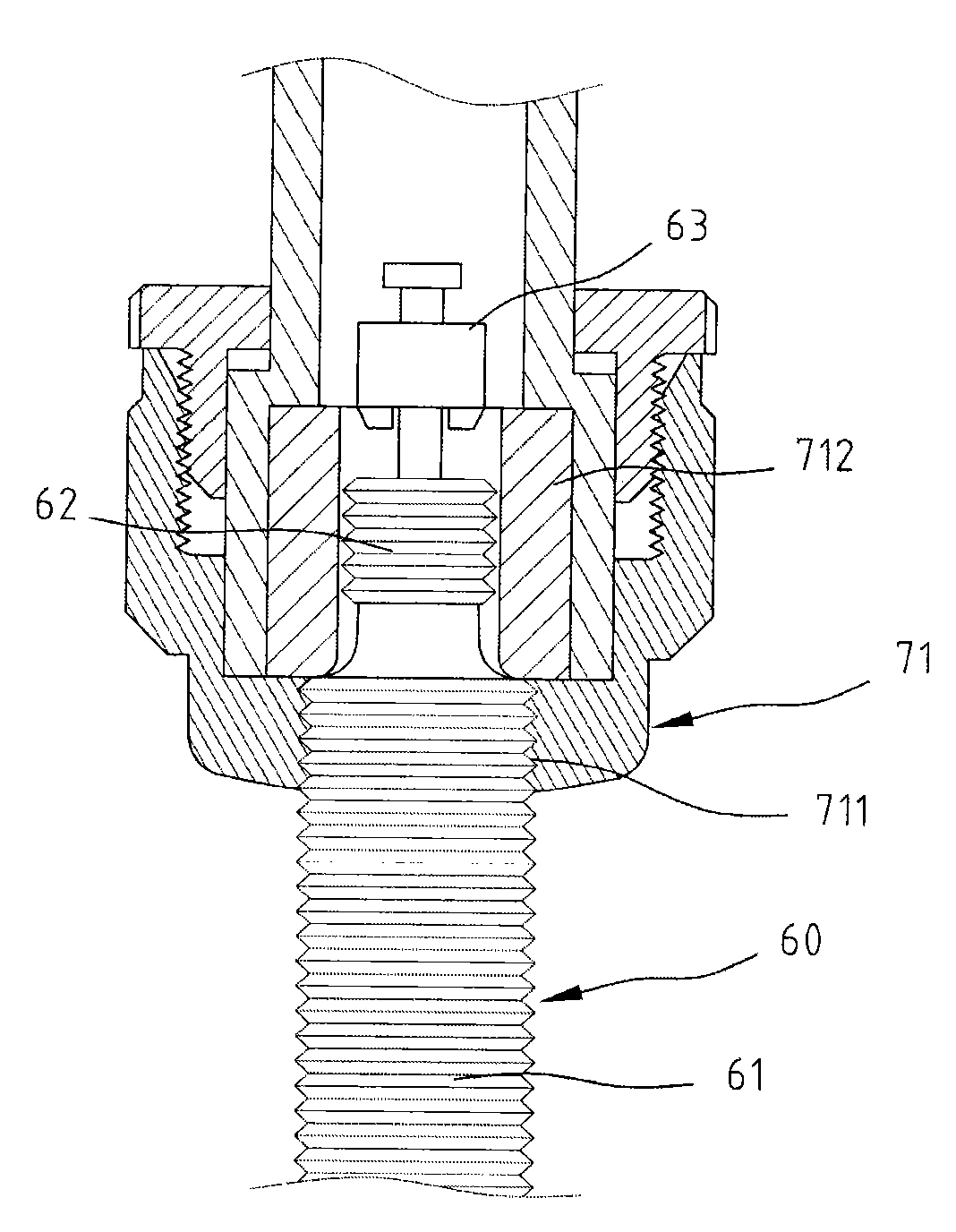

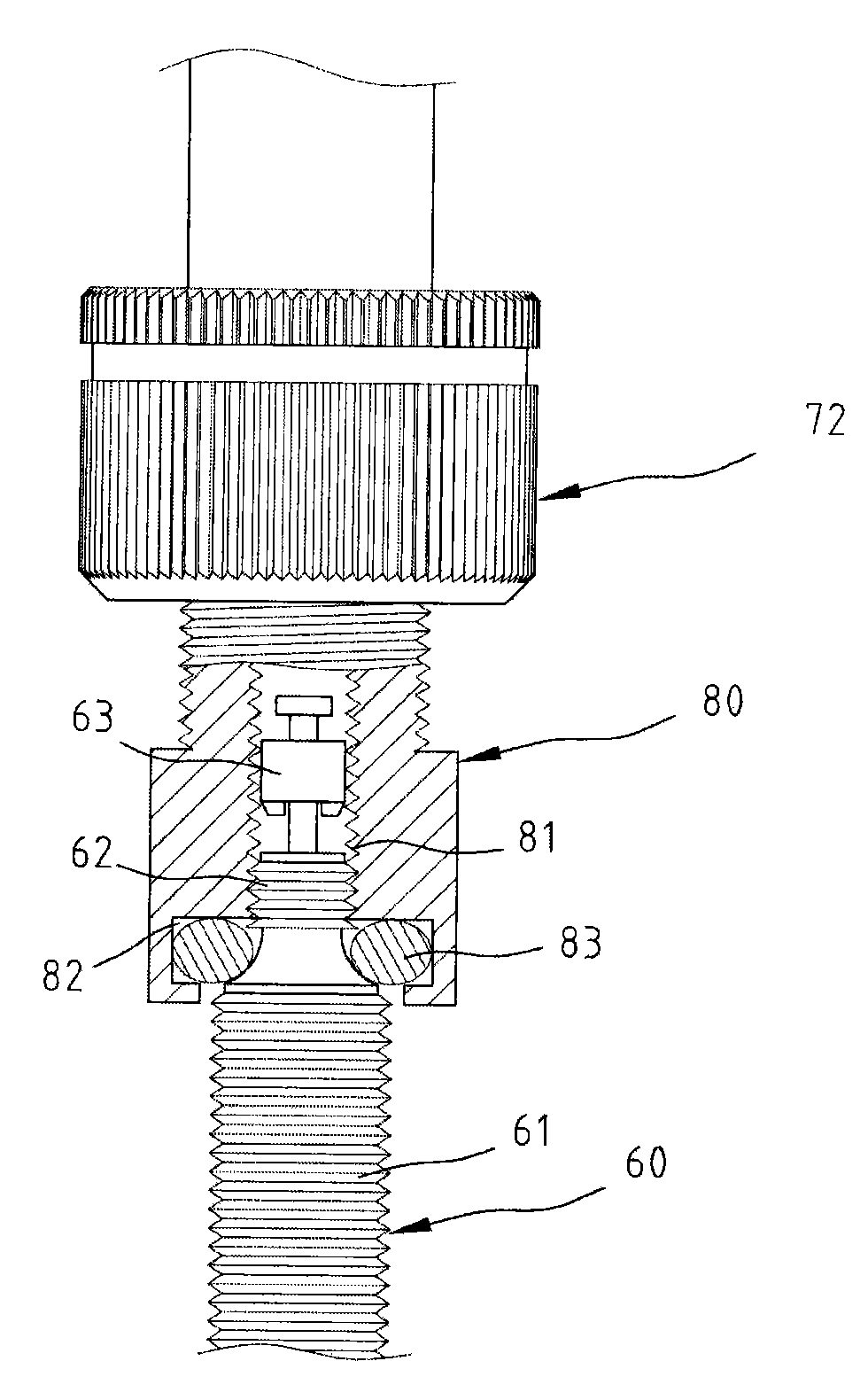

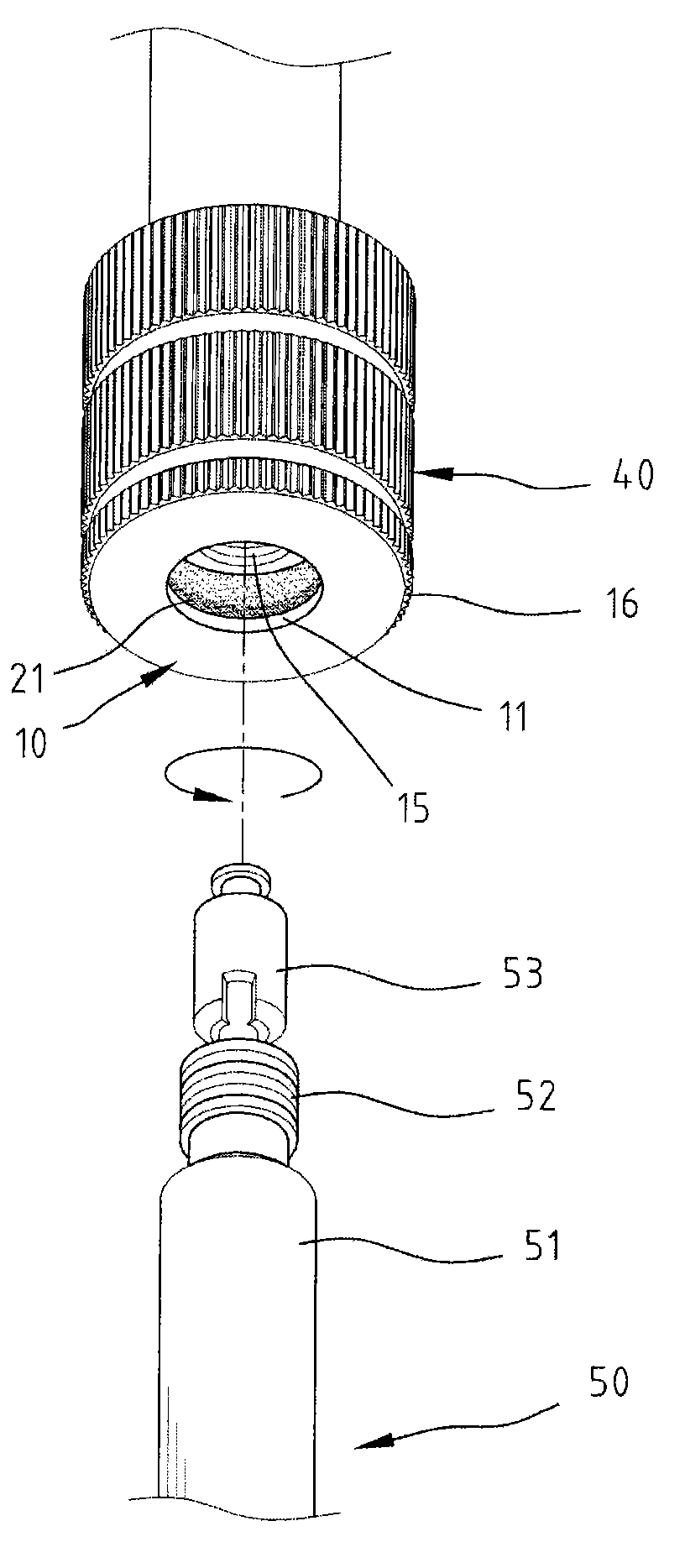

[0030] Figure 4 shows a schematic diagram of structural decomposition of the present invention and Figure 5 The disassembled sectional view, under the background of the invention of the so-called French air nozzle 50 of the present invention screwed with the inflation nozzle, the present invention is the design of the air intake end with a central pipe seat 30 connected to the inflation tube of the pump, in the central pipe seat 30 A central hole 312 is formed at the center of one end connecting the aforementioned inflatable tube, and a chamber 31 with a larger diameter than the other end of the central hole 312 is formed. 311; and the periphery of the central tube base 30 is provided with a shell 40, the shell 40 is a U-shaped body, one end of the larger opening is inserted from the central hole 312 of the central tube base 30, and the other end of the larger opening is provided with a circular diameter Smaller through hole 42, the outer edge surface of the through hole 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com