Thin film transistor (TFT) substrate, manufacturing method thereof and display device

A thin film transistor and substrate technology, applied in the field of electrowetting display devices, can solve the problems of poor optical quality and complex structure, and achieve the effects of simple structure, convenient use and good optical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

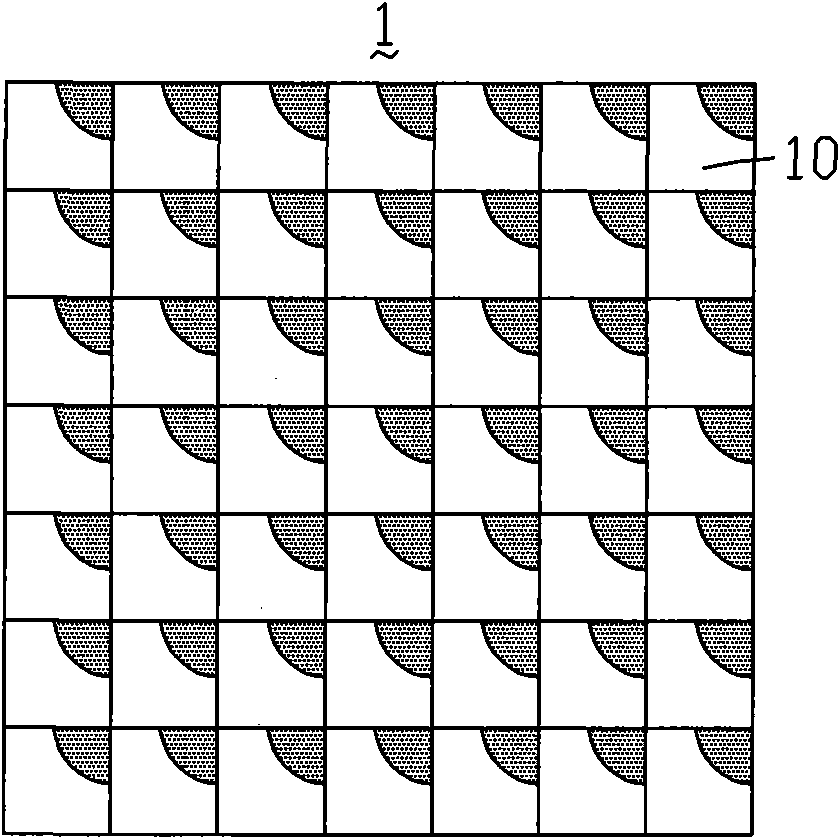

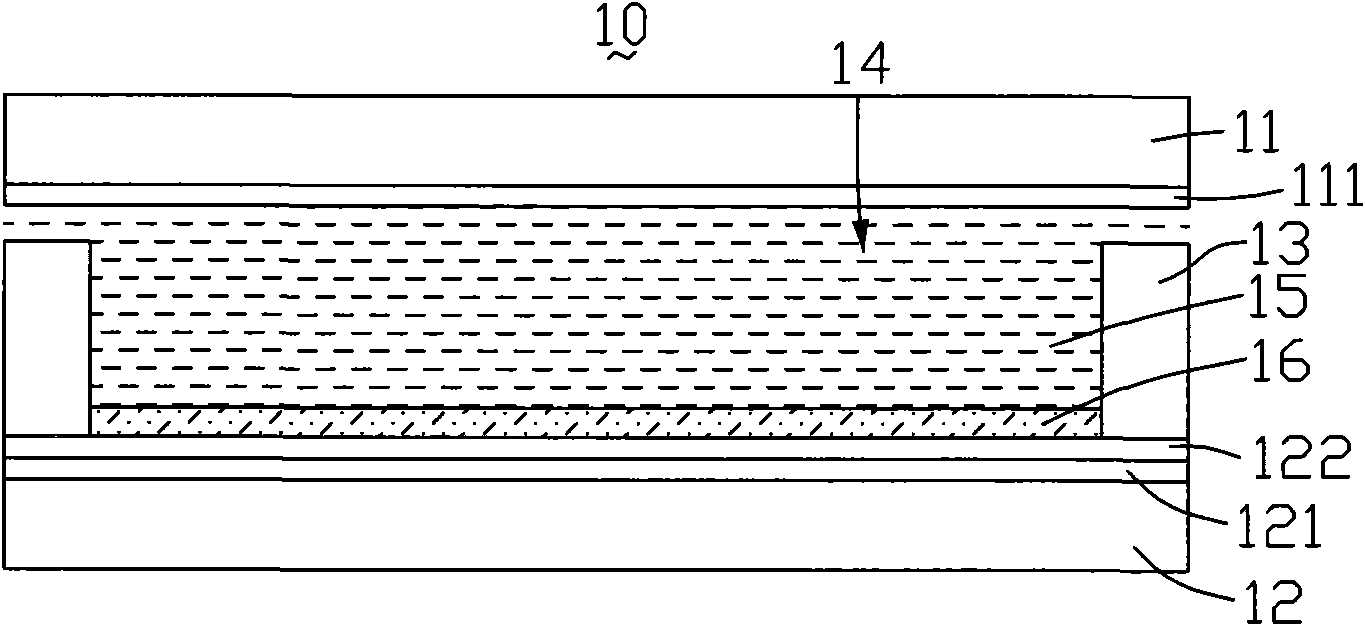

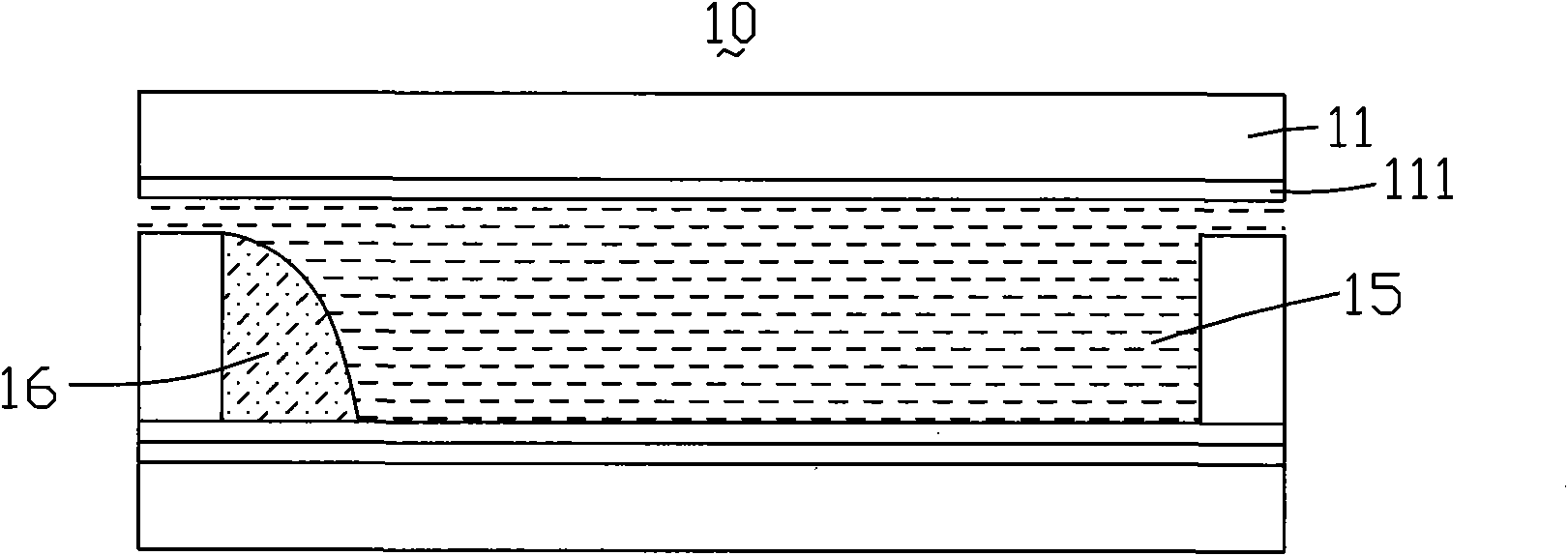

[0035] see Figure 4 , is a partial structural schematic diagram of the first embodiment of the electrowetting display device of the present invention. The electrowetting display device 4 is a transmissive display device, which includes a facing substrate 41, a thin film transistor substrate 42 opposite to the facing substrate 41, and a thin film transistor substrate 42 located between the facing substrate 41 and the thin film transistor substrate 42. The sealant 49 between them, a plurality of intersecting partitions 43 between the opposite substrate 41 and the thin film transistor substrate 42 arranged in rows and columns, and a backlight module (not shown) adjacent to the thin film transistor substrate 42 . The TFT substrate 42 includes a frame glue setting area (not shown). The frame glue 49 is arranged in the frame glue setting area and abuts the two substrates 41, 42 and cooperates with the two substrates 41, 42 to form a closed first receiving space 441, and the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com