Internal magnetic core connecting line

A technology of connecting wire and magnetic core, applied in the field of data transmission, can solve the problems of poor anti-electromagnetic wave interference effect, affecting product quality, complex processing technology, etc., achieving the effect of less processing technology, saving raw materials, and reducing injection molding of magnetic cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

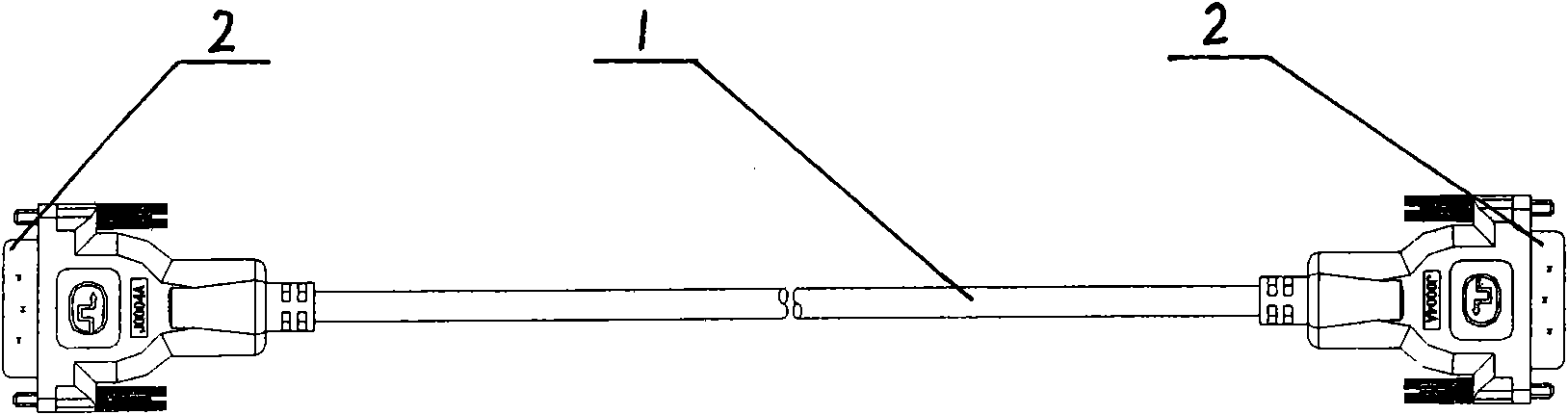

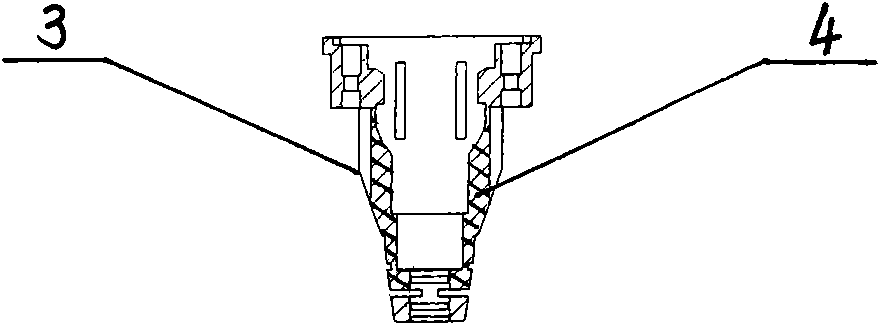

[0010] As shown in the drawings, a connecting wire with a built-in magnetic core is provided with a connecting wire 1, and the two ends of the connecting wire are respectively connected with connectors 2. The structures of the connecting wire 1 and the connector 2 and the interconnection relationship between them are similar to those of the prior art. The same, this will not go into details, the feature of the present invention is that the housing 3 of the joint 1 is provided with a magnetic core 4, and the housing 3 is injection molded with PVC plastic. When injection molding, the magnetic core 4 is directly placed in the injection mold cavity and injected with PVC. The joint housing is made, so that the magnetic core 4 is buried in the housing 3, so that the magnetic core 3 is in the joint 2, the distance is zero, and the shielding effect is good. The present invention has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com