Absorbing article

一种吸收性、高吸收性的技术,应用在吸收垫、医药科学等方向,能够解决损害吸液性垫柔软性等问题,达到效果佳的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

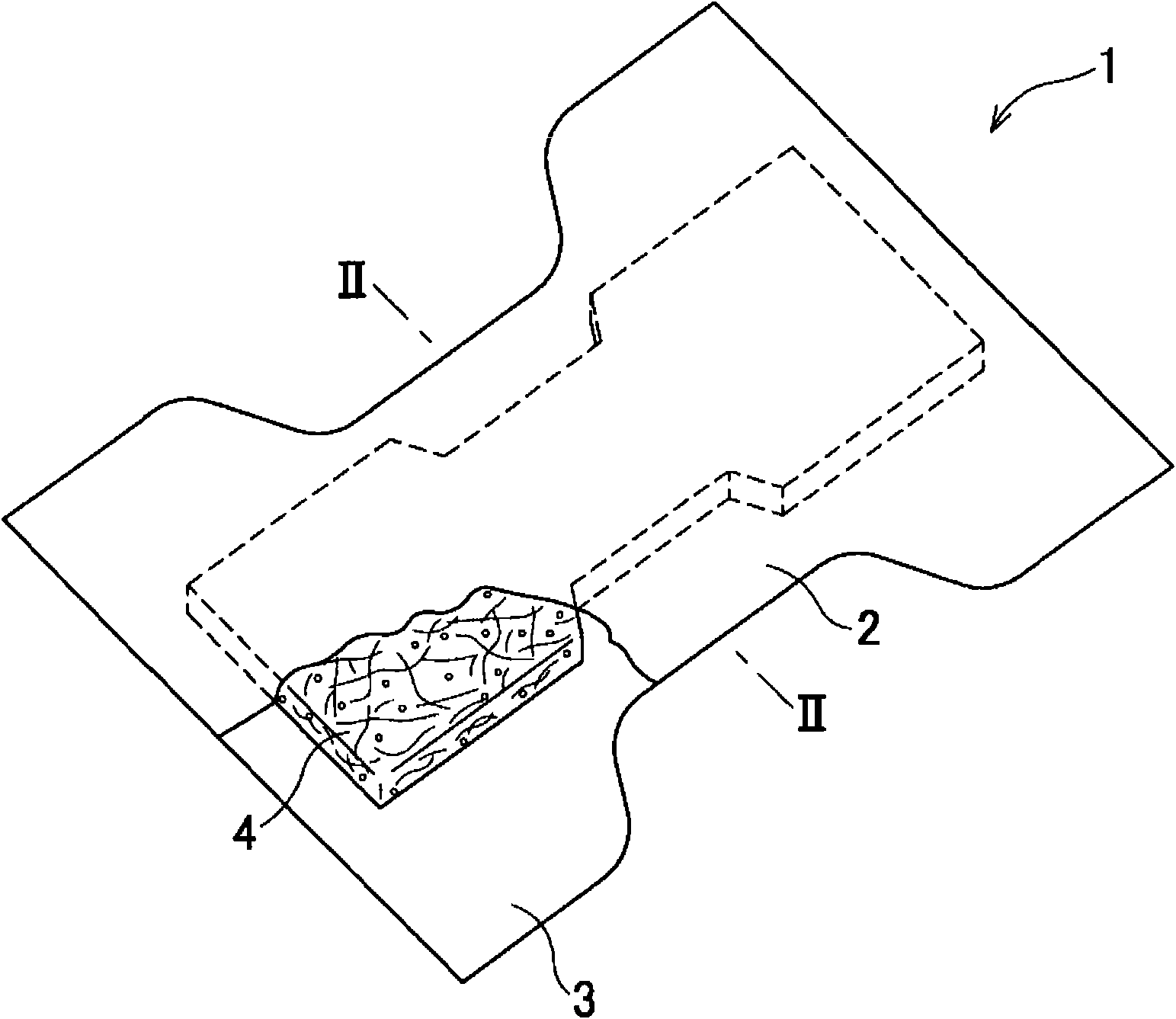

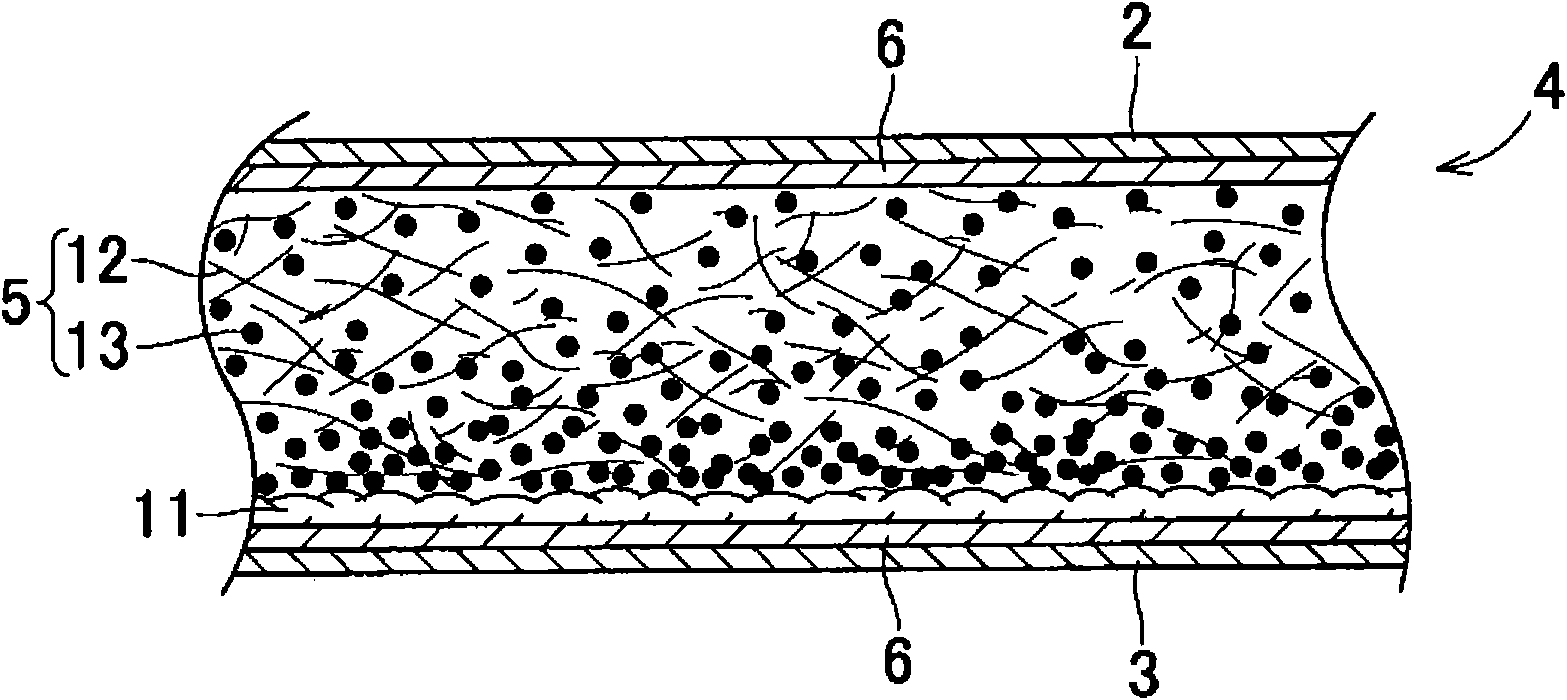

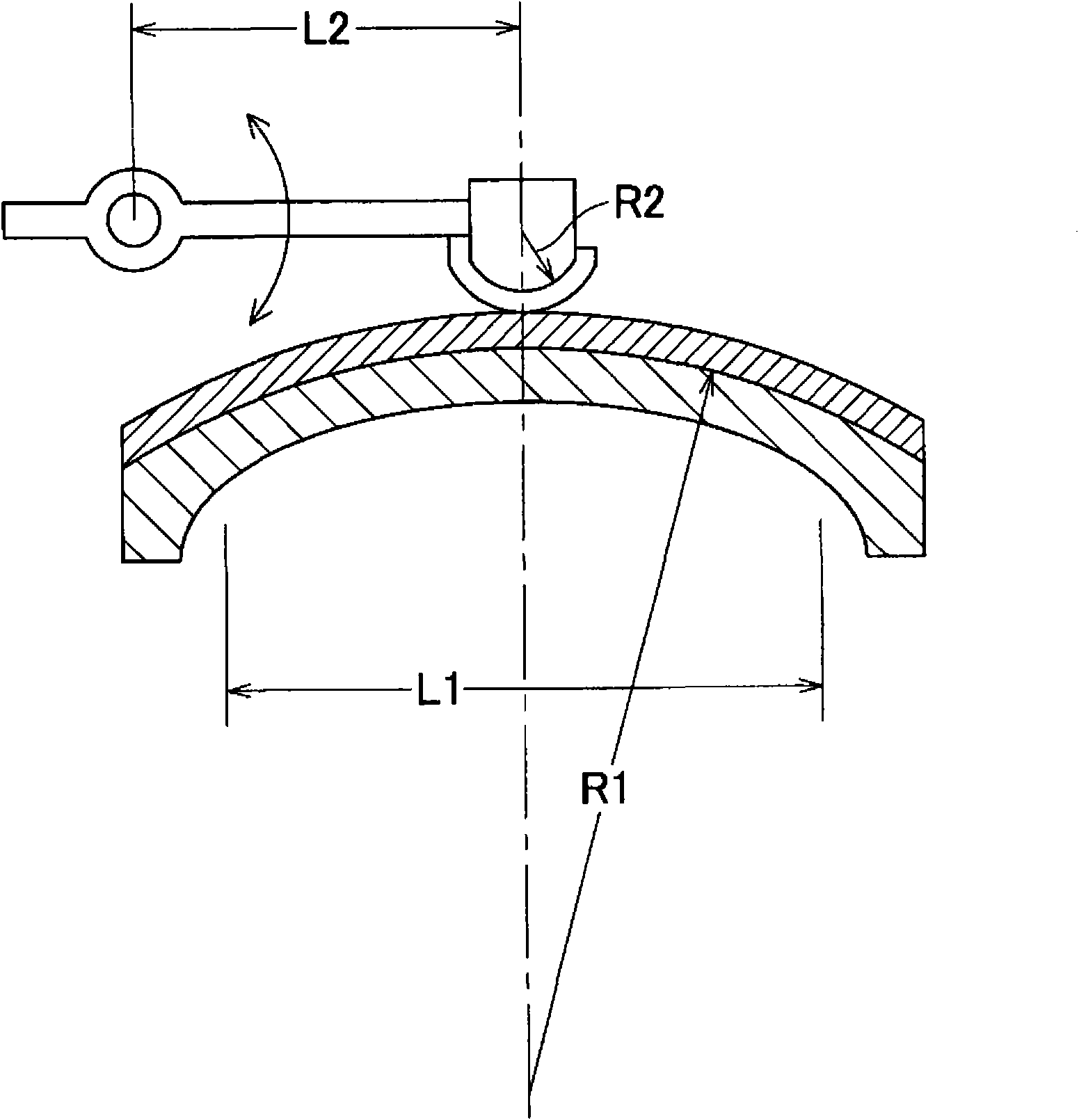

[0066] Nonwoven fabrics of Examples 1 to 3 and Comparative Examples 1 to 3 shown below were produced, and the fluff height measurement and tensile test thereof were performed. In addition, a diaper-type sample having an absorbent body 4 using these nonwoven fabrics was produced, and the effect of suppressing shape collapse of the liquid-absorbent mixture 5 was confirmed.

[0067] The non-woven fabrics produced are all made of long fibers with a core-sheath structure with polypropylene (PP) as the core by the spunbond method. Polyethylene (PE) with different melting points is used for the sheath of the fiber. By changing the temperature of the heat welding, the strength of the heat welding is different, thereby adjusting the height of the fluff. In addition, the fiber diameter of the long fibers is 20 to 25 μm.

[0068] More specifically, as shown in Table 1, in Example 1, PE with a melting point of 125°C was used as the material of the sheath to produce a sheath with a mass o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com