Vacuum line

A technology of vacuum pipelines and pipelines, applied in the direction of pipes/pipe joints/pipes, shock absorbers, adjustable connections, etc., which can solve the problems of weakening the transmission of vibration and affecting functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

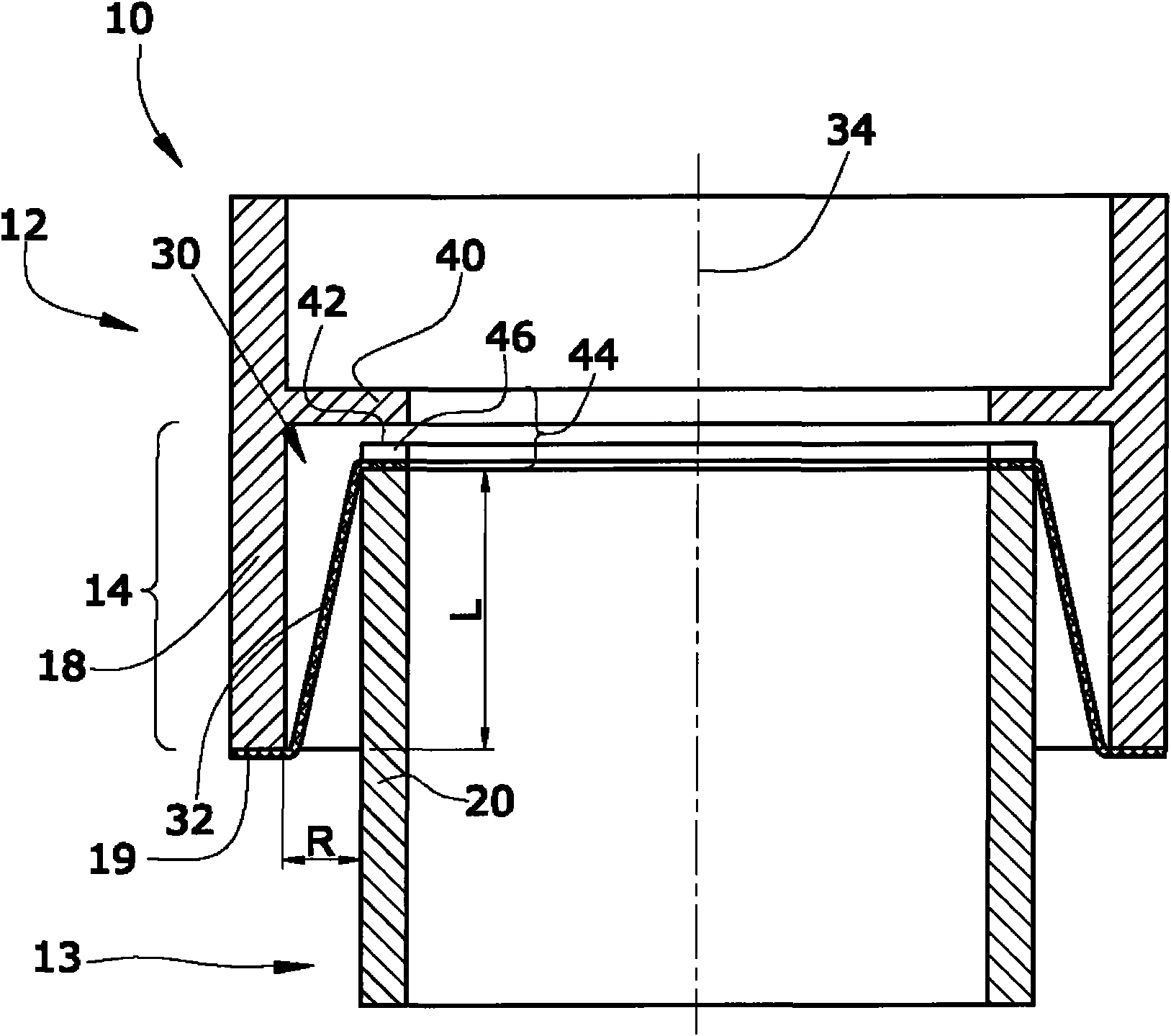

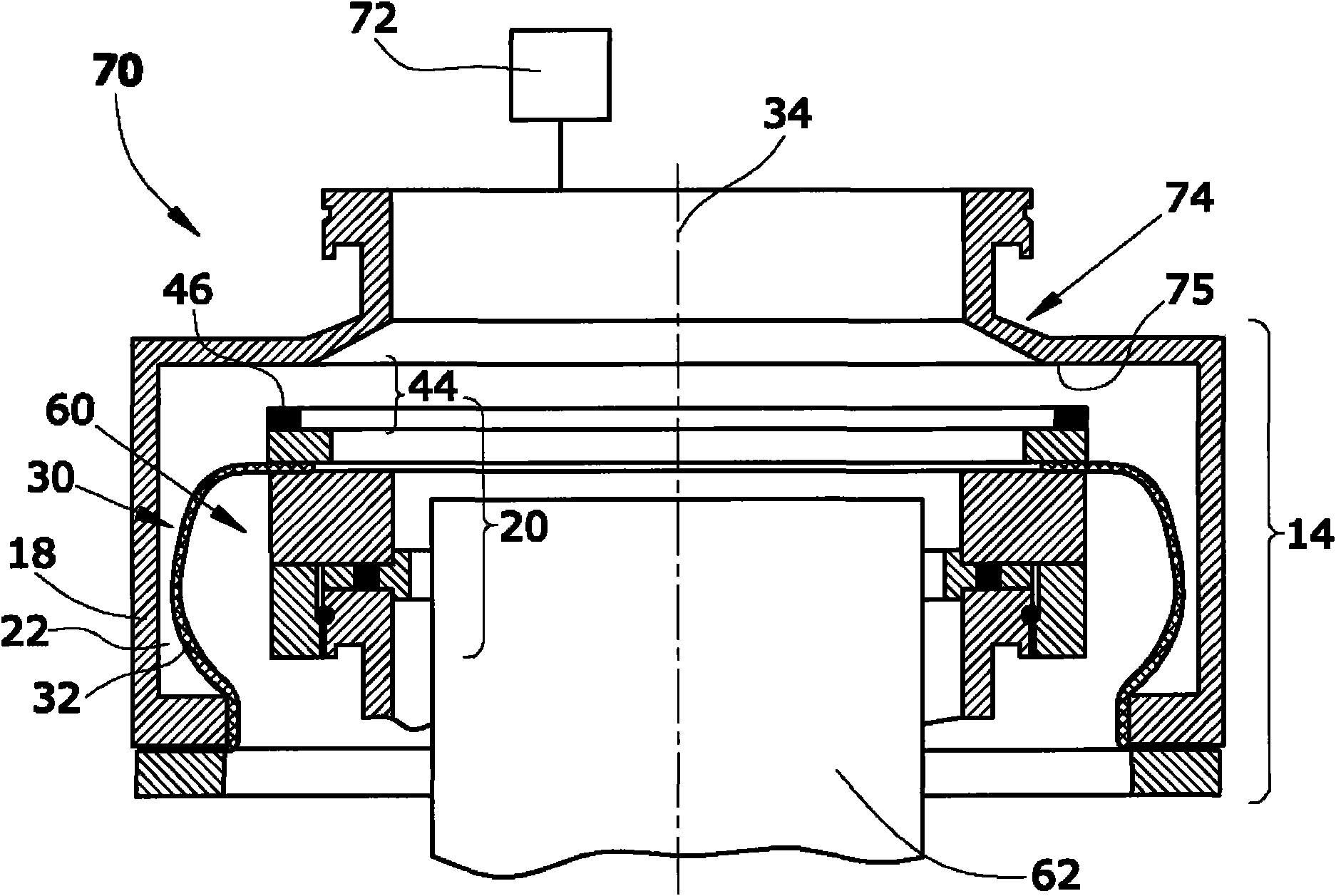

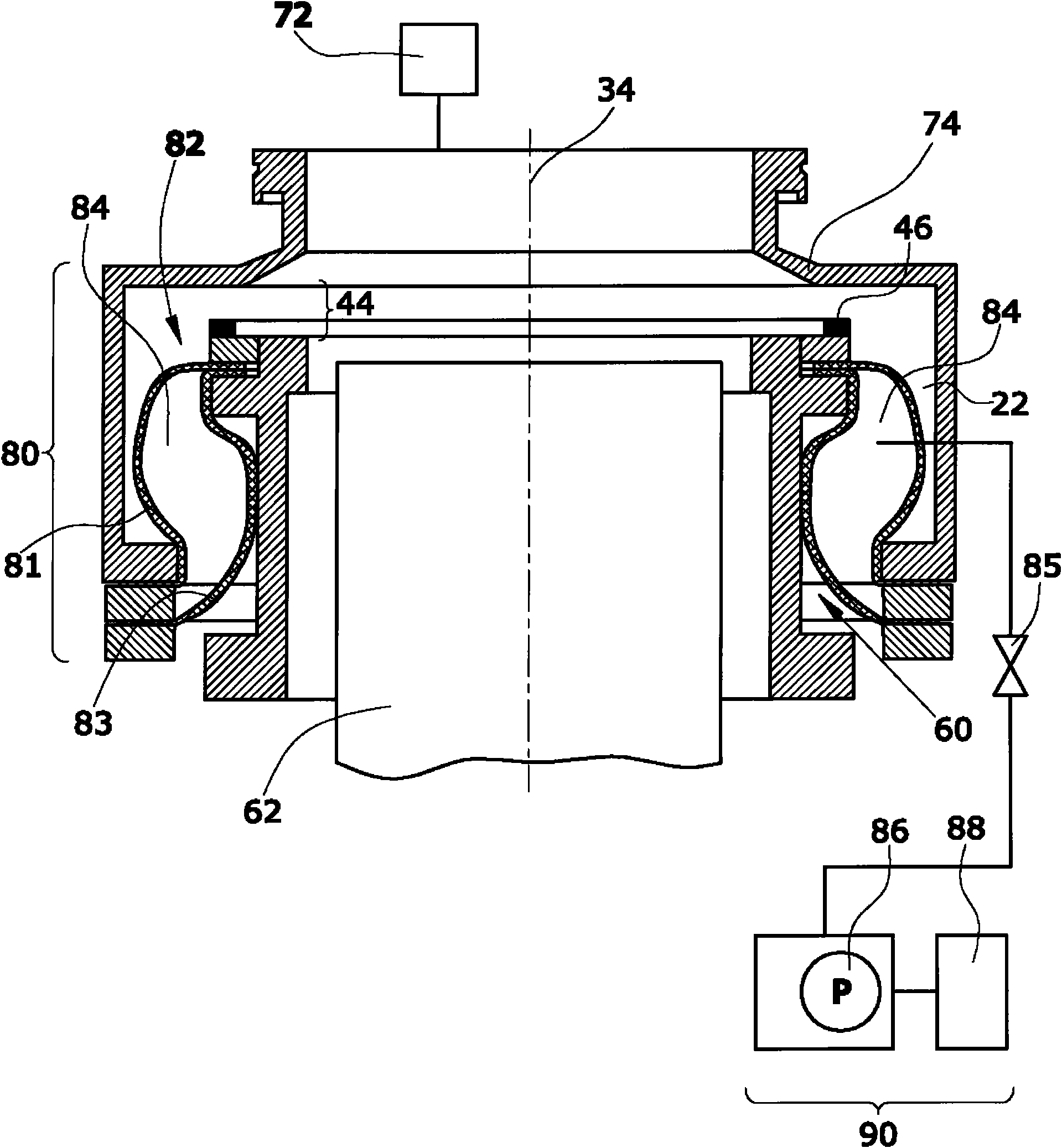

[0023] figure 1 A vacuum line 10 is schematically shown formed from two line parts 12 , 13 which are connected to one another via a vibration damper 14 . In the operating state, negative pressure is distributed in the vacuum line 10 and atmospheric pressure is distributed outside the vacuum line 10 .

[0024] The upper piping part 12 includes a vertical outer tube 18 into which a vertical inner tube 20 fits. The diameter of the outer tube 18 and inner tube 20 may be circular, but need not be. The cross-sectional profile of the outer tube 18 and the inner tube 20 may be cylindrical, but need not be.

[0025] The opening edge 42 of the inner tube 20 is connected with the opening edge 19 of the outer tube 18 through a flexible stretch sleeve 30, which is formed by a flexible but inelastic or little elastic sleeve hose 32. form. The opening edges of the sleeve hose 32 are connected in a vacuum-tight manner to the corresponding opening edges 19 , 42 of the outer tube 18 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com