Wingtip eddy diffusion device

A diffusion device and wingtip technology, applied in the direction of wing adjustment, heat reduction structure, etc., to achieve the effect of small size, excellent comprehensive performance, and small increase in structural weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the drawings and embodiments.

[0019] In order to solve the above shortcomings, the present invention proposes a wingtip vortex diffusion device that can reduce the induced drag of the aircraft and improve the lift-drag ratio.

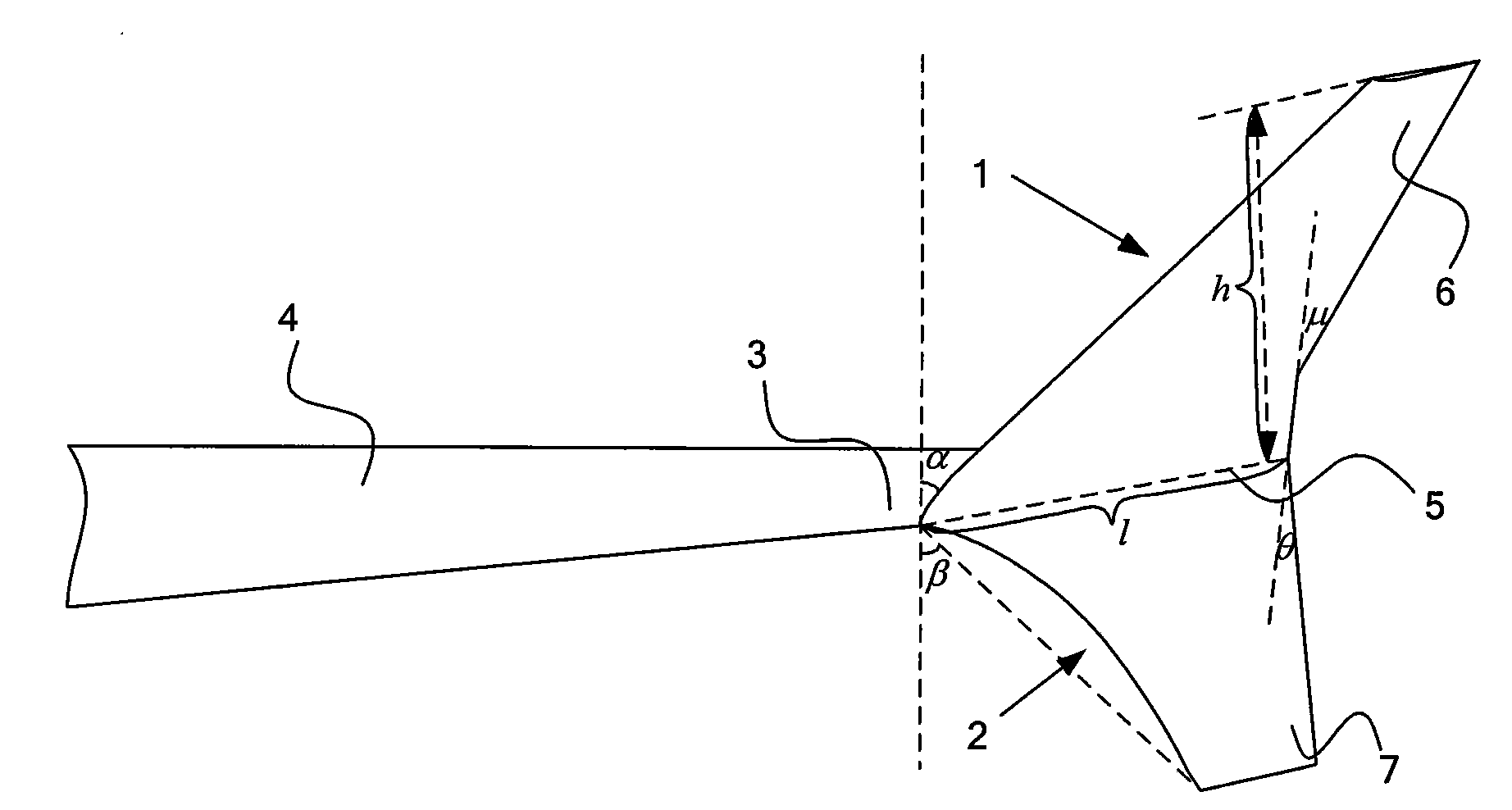

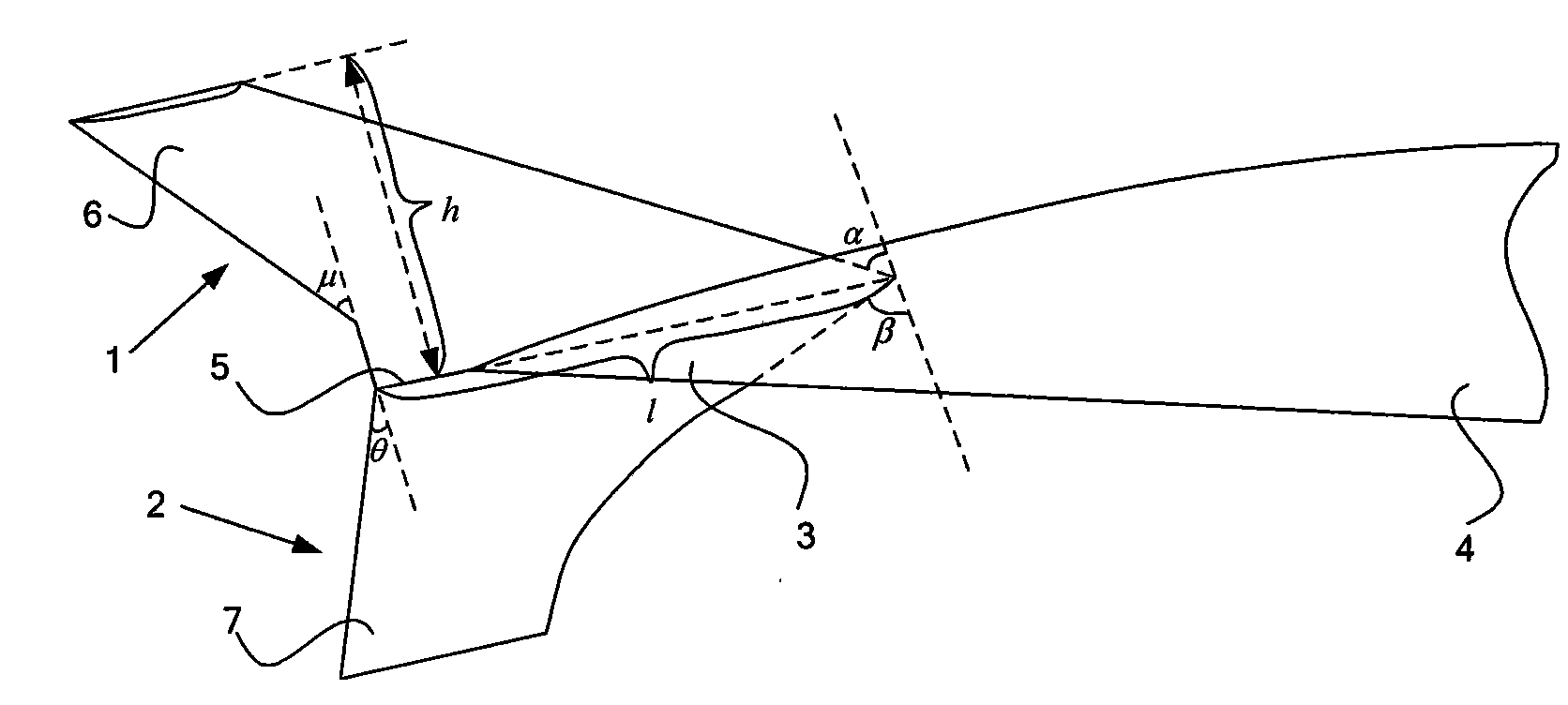

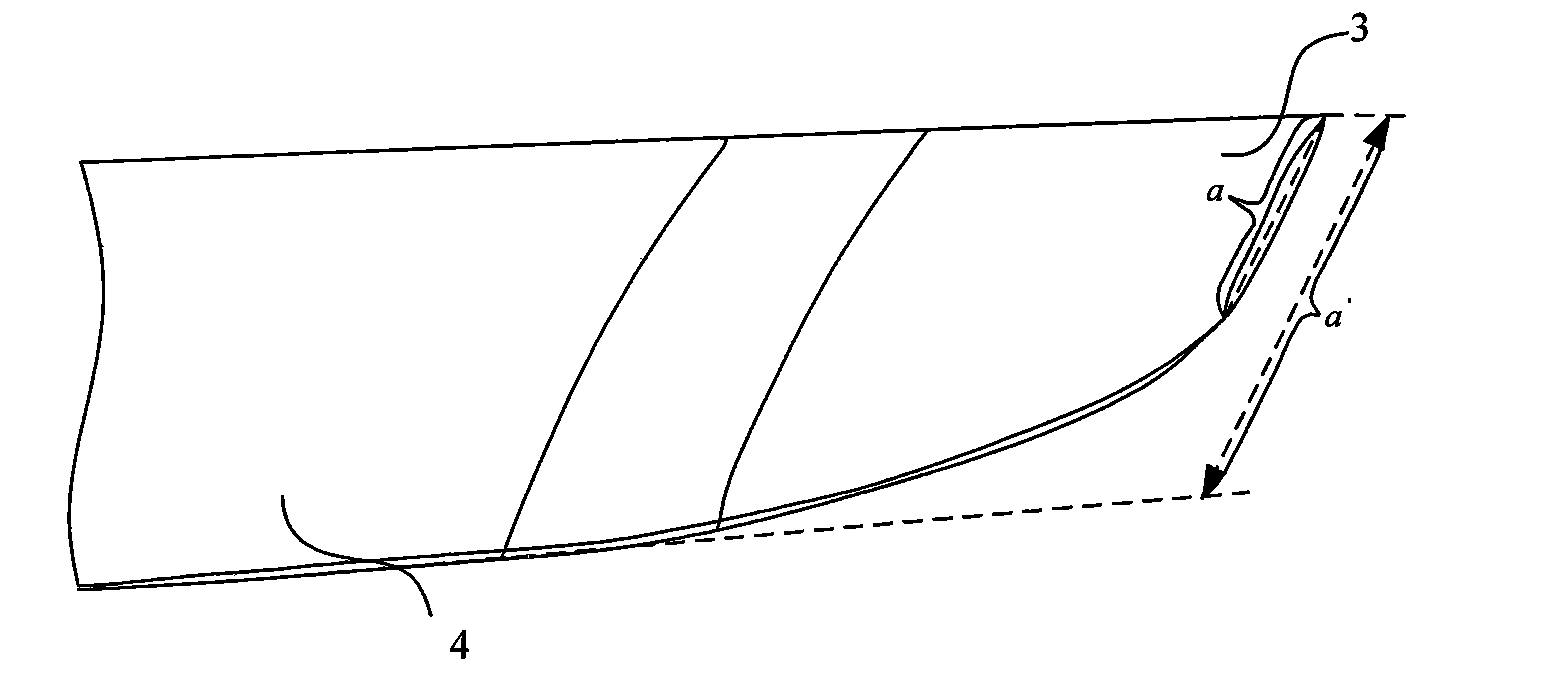

[0020] The invention is a wingtip vortex diffusion device, such as figure 1 , figure 2 , image 3 As shown, it is composed of an upper winglet 1 and a lower winglet 2. The span of the upper winglet h is between 400 and 500mm, and the leading edge sweep angles α and β of the upper winglet 1 and the lower winglet 2 are between 60 and 70 degrees, and both are larger than the rear of the wing 4. Sweep angle, the trailing edge sweep angle μ and θ of the upper winglet 1 and the lower winglet 2 are between 10 and 50 degrees, so that the airflow velocity on the two winglets is greater than the incoming flow velocity, and the upper winglet 1 and the lower winglet 2 The airfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com