Oil extractor balance weight method and high efficient energy saving beam oil extractor

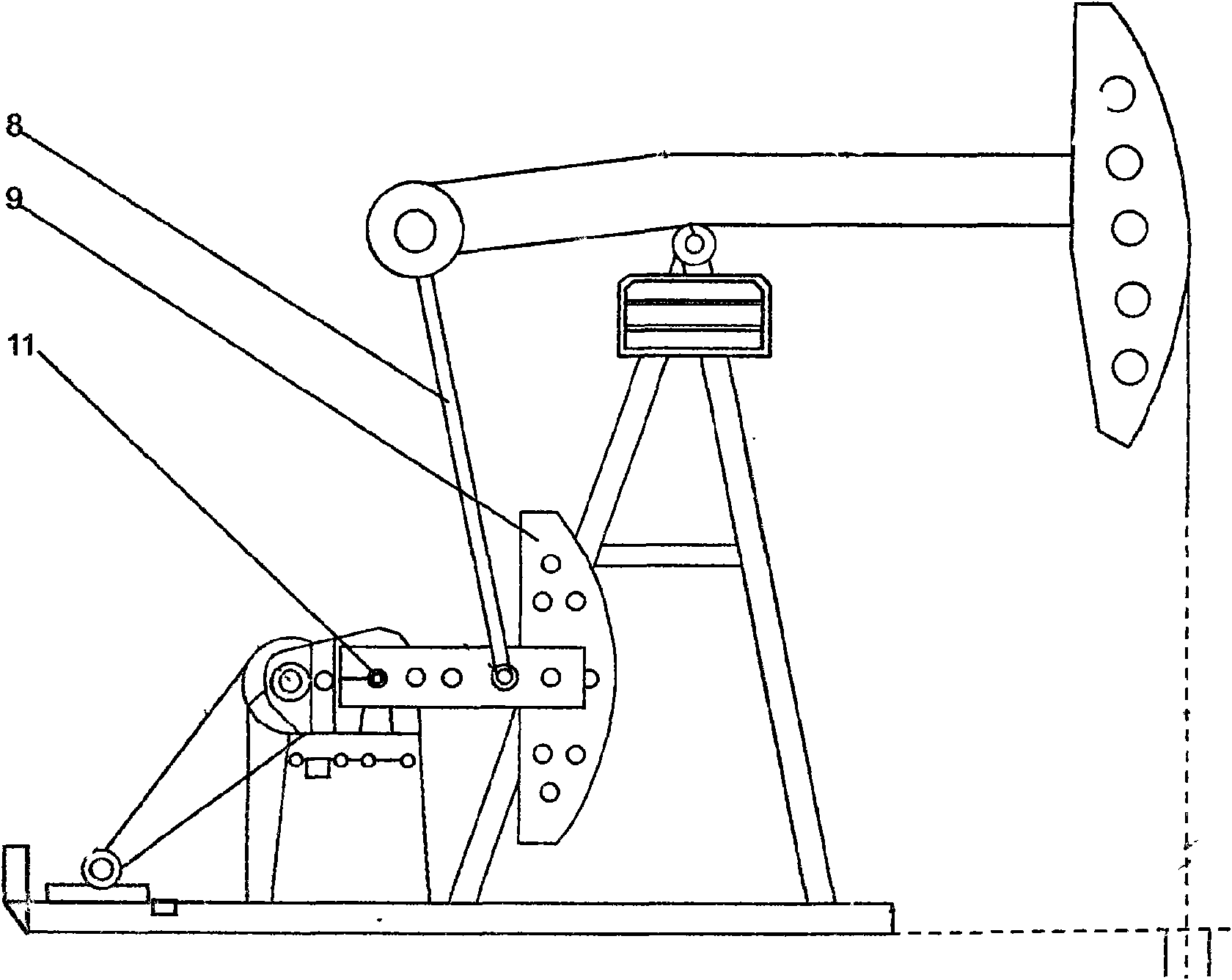

A technology of beam pumping unit and balance counterweight, which is applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., which can solve the problems of energy waste, power factor reduction, power grid impact, etc., and reduce electric energy waste, reduce output torque, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

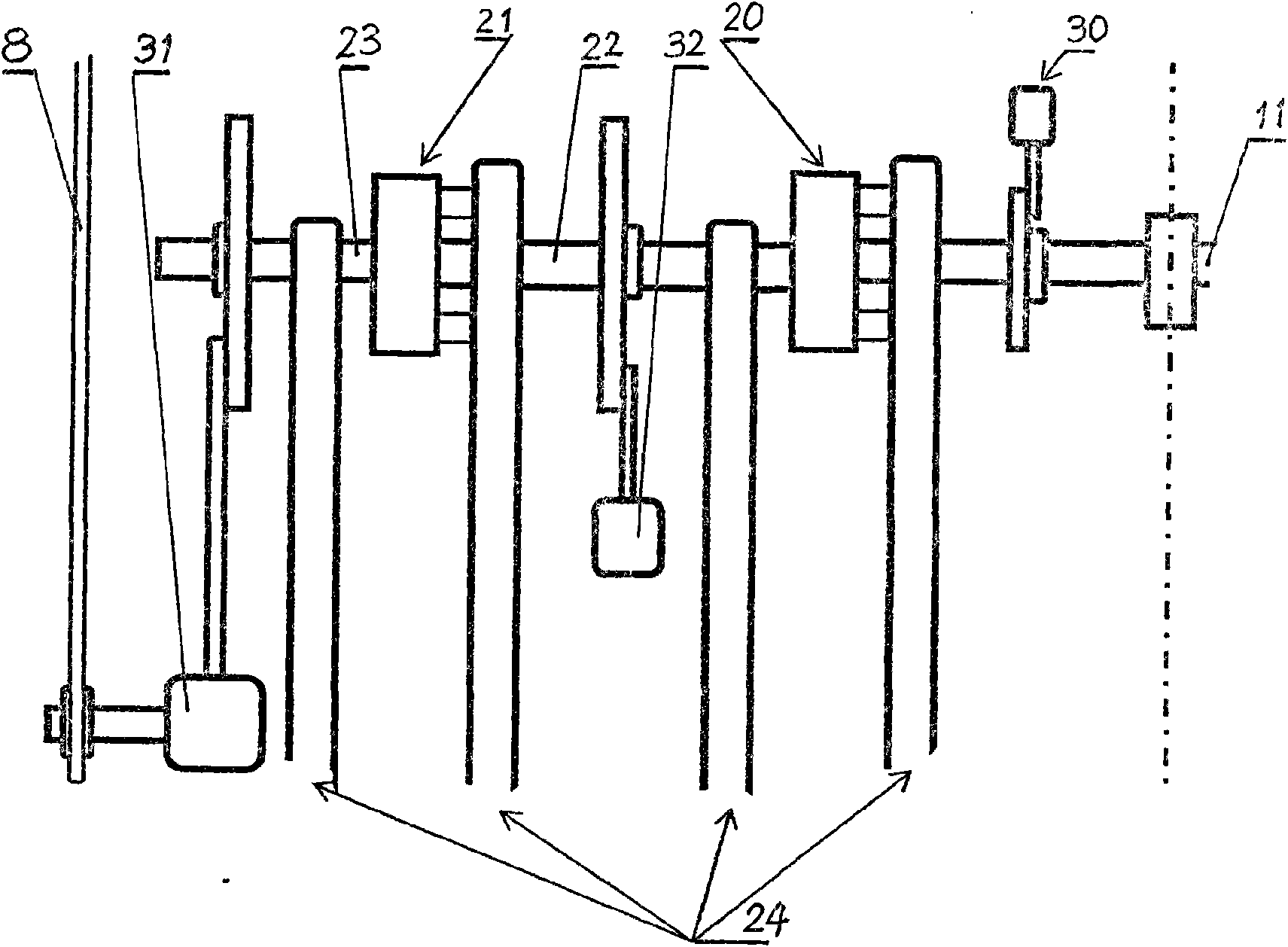

[0020] The method for balancing the counterweight of the pumping machine provided by the patent application of the present invention, its mathematical model is based on the following principles, as Figure 9 As shown, the curve ① is the load torque curve of the existing beam pumping unit. Through the setting of a series of balancing devices, the output torque of the motor can be stabilized, namely

[0021] Motor output torque = load torque of pumping unit - torque provided by series counterweight device = constant,

[0022] That is, T(input)=T(demand)-T(balance)=C

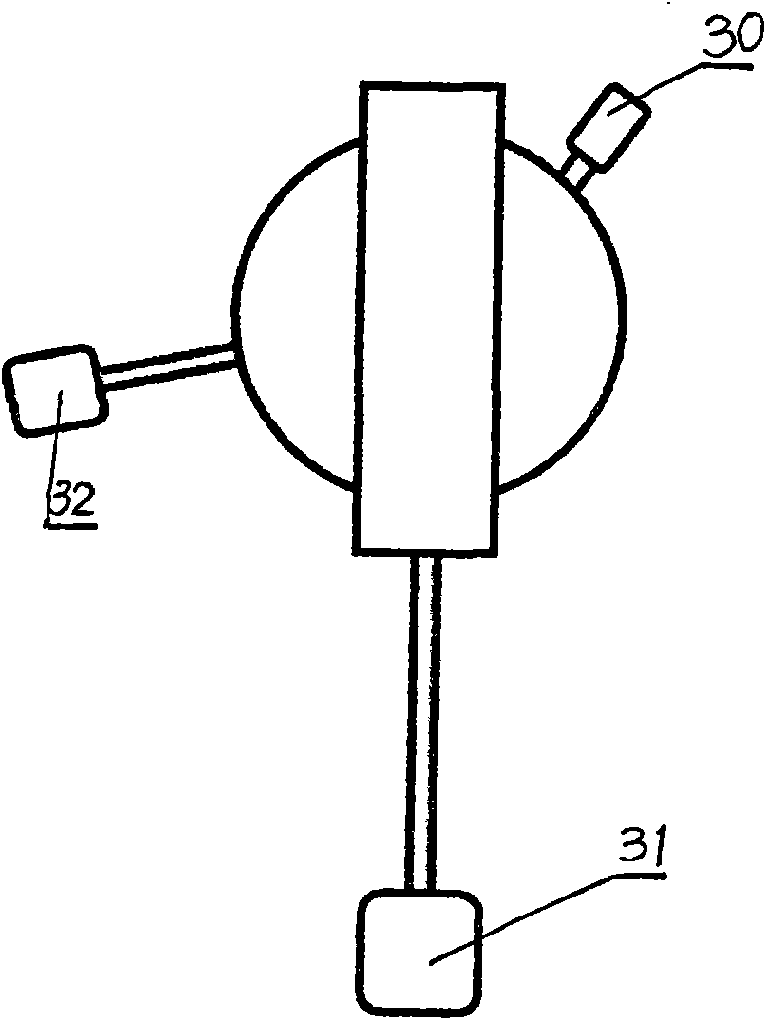

[0023] The series of balance weight devices are equipped with multi-stage counterweight rotating bodies with corresponding arm lengths and counterweight torques on the segmented deceleration axis. Since the above-mentioned counterweights that play a balancing role are made of fixed shafts and fixed arm lengths, Circular motion, then take a trigonometric series with a fixed number of items in the positive or co-xua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com