Insulating pull rod for breaker

A technology of insulating pull rods and circuit breakers, which is applied in the direction of high-voltage air circuit breakers, circuits, electrical components, etc., can solve the problems of inconvenient, fast, efficient, labor-intensive, time-consuming and labor-intensive assembly, and reduce work efficiency, so as to solve the problem of external partial discharge deviation High and corona, improve work efficiency, improve insulation performance and withstand voltage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

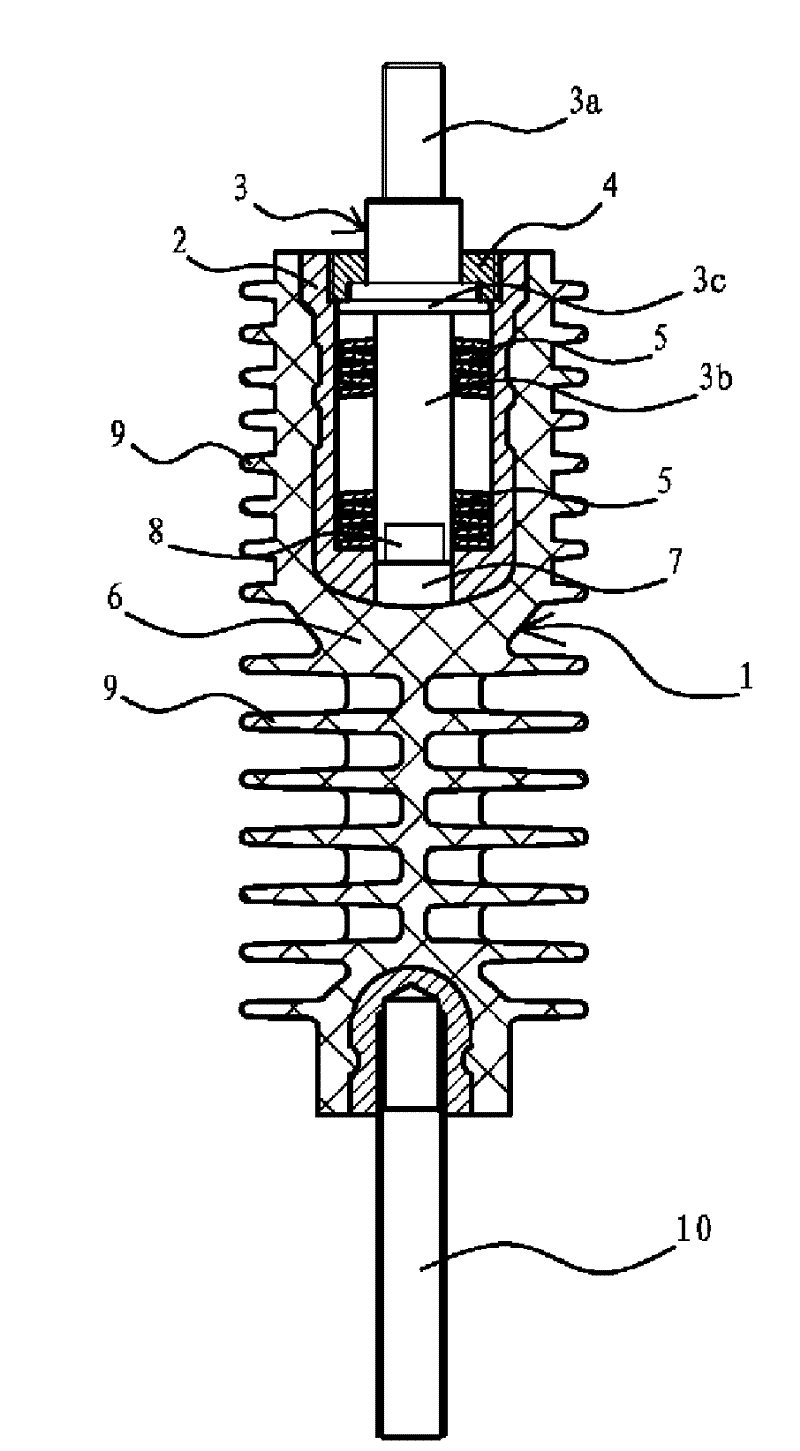

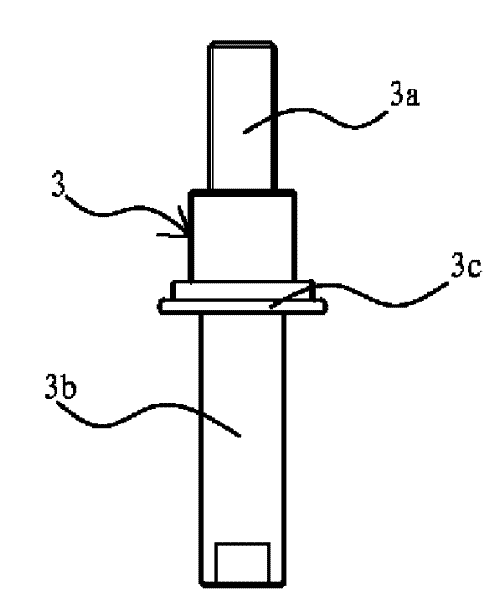

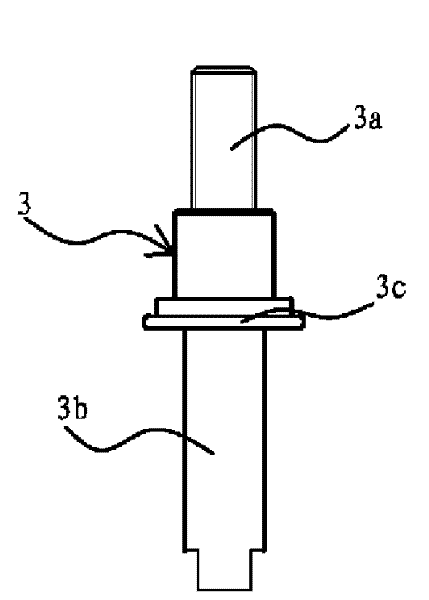

[0040] Such as figure 1 , 2 , 3, 4 and Figure 5 As shown, the insulating pull rod of this circuit breaker is an insulating pull rod 1250A-31.5KA / 3150A-31.5KA suitable for vacuum circuit breakers in 24KV high-voltage switchgear, including connecting rod 3, disc spring 5, spring base 2, rod body 1, and the lower end of rod body 1 A connecting screw 10 is fixedly connected, the spring base 2 is cylindrical and is fixedly connected with the upper end of the rod body 1 , and an outer nut 4 is threadedly connected to the opening at the upper end of the spring base 2 . The connecting rod 3 includes a screw rod 3a and a screw sleeve 3b. The screw sleeve 3b is provided with a retaining edge 3c, which divides the screw sleeve 3b into upper and lower parts. The outer nut 4 is set on the upper part of the screw sleeve 3b and leans against the On the retaining edge 3c, the disc spring 5 is set in the spring base 2 and is sleeved on the lower part of the screw sleeve 3b of the connecting...

Embodiment 2

[0047] Such as Figure 6 , 7 , 8, 9 and Figure 10 As shown, the insulating pull rod of this circuit breaker is a 2000A 31.5KA insulating pull rod suitable for a vacuum circuit breaker in a 40.5KV high-voltage switchgear, including a connecting rod 3, a disc spring 5, a spring base 2 and a rod body 1, and the lower end of the rod body 1 is fixedly connected with a connecting screw. 10. The spring base 2 is cylindrical and fixedly connected to the upper end of the rod body 1 , and the outer nut 4 is threadedly connected to the opening of the upper end of the spring base 2 . The connecting rod 3 includes a screw rod 3a and a screw sleeve 3b. The screw sleeve 3b is provided with a retaining edge 3c, which divides the screw sleeve 3b into upper and lower parts. The outer nut 4 is set on the upper part of the screw sleeve 3b and leans against the On the retaining edge 3c, the disc spring 5 is set in the spring base 2 and is sleeved on the lower part of the screw sleeve 3b of the ...

Embodiment 3

[0054] The difference between this embodiment and Embodiment 1 is that in this embodiment, the circumferential positioning structure between the connecting rod 3 and the spring base 2 is a non-circular stop edge 3c and a stop edge 3c arranged on the spring base 2 A non-circular hole 7 matching the non-circular retaining edge 3c. Other structures are the same as those in Embodiment 1 and will not be described again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com