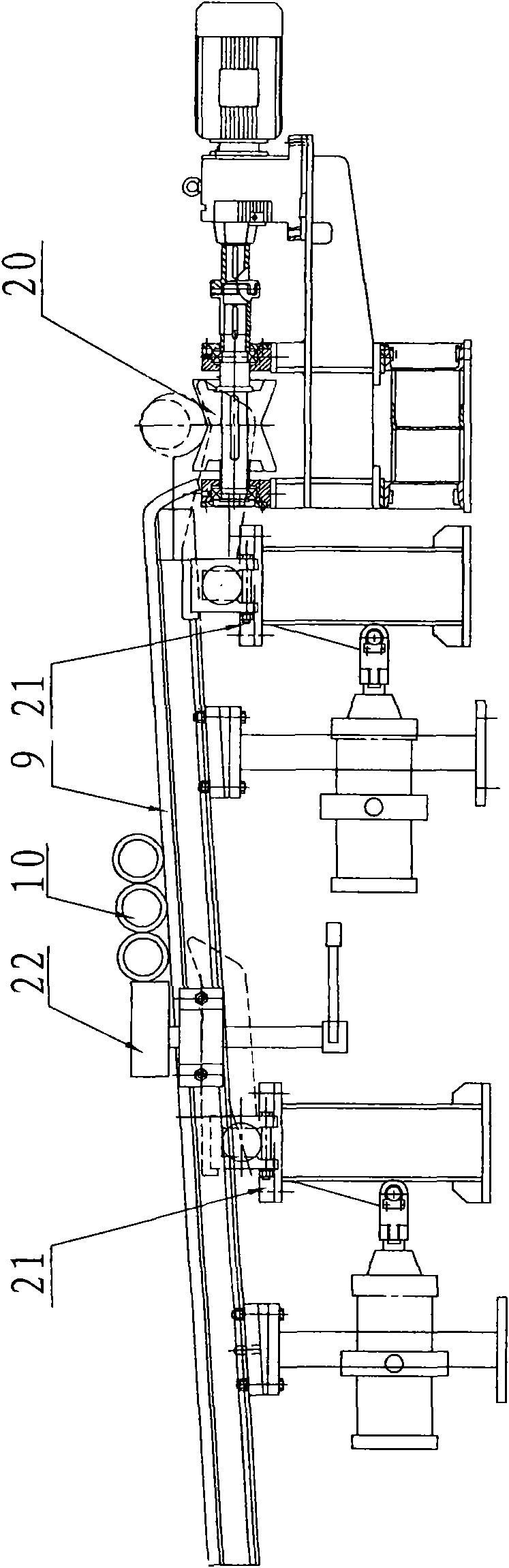

Steel pipe stop and feed device

A technology of feeding device and retaining material, which is applied in metal processing and other directions, can solve the problems that the work efficiency of the wide band saw cannot be fully exerted, the daily output of the steel pipe production line is affected, and the energy consumption of steel pipe transfer and transportation is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

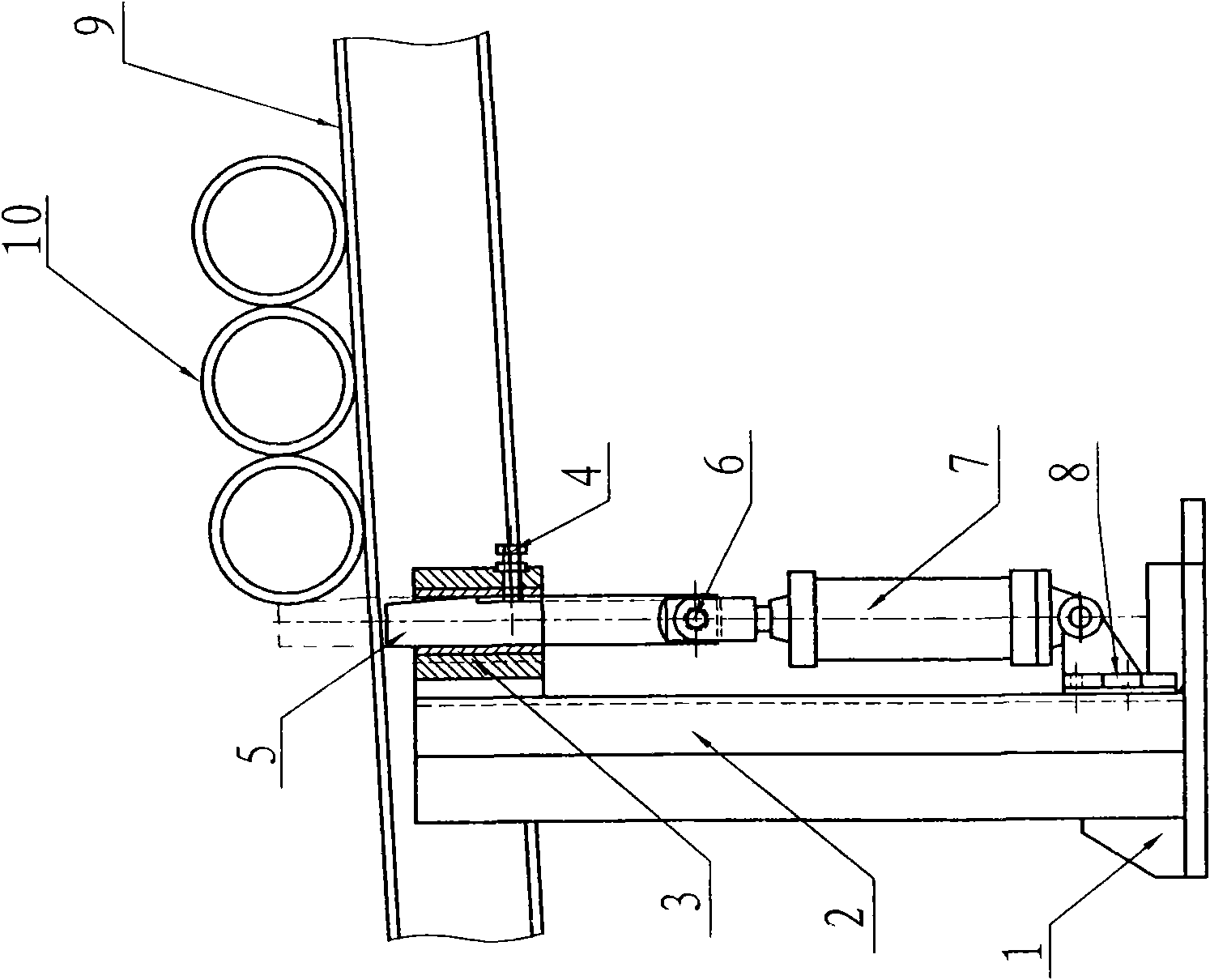

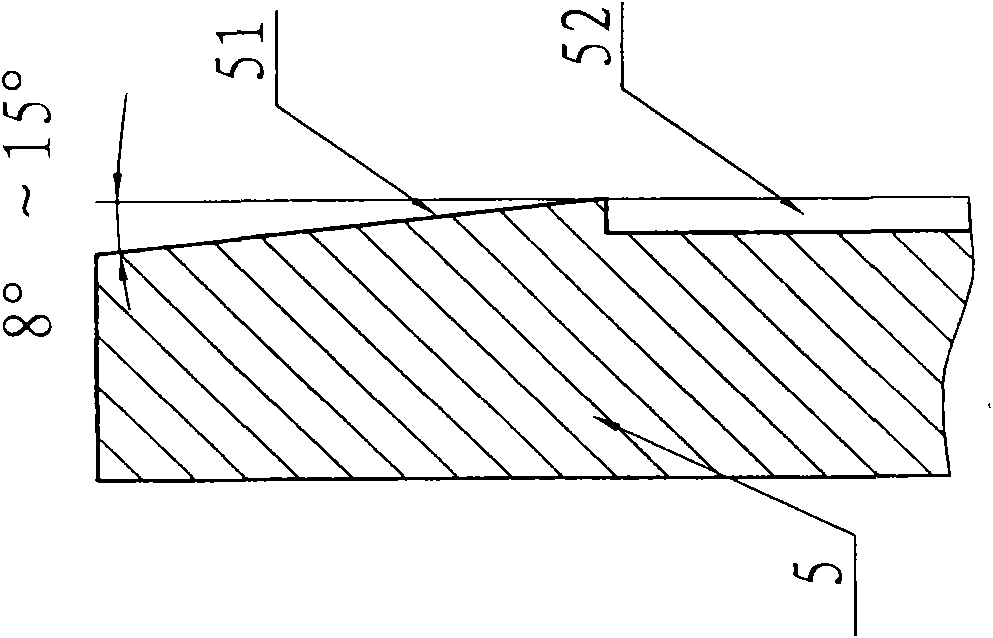

[0014] Embodiment 1: The steel pipe blocking and feeding device, such as figure 2 As shown, it includes an inclined beam 10 and a lifting stop mechanism, and the lifting stop mechanism includes a base 1, a column 2, a guide seat 3, an orientation screw 4, a stop rod 5, an active connection sleeve 6, a cylinder 7 and ear Seat 8, column 2 is fixed on the base 1, guide seat 3 is installed on the upper section of column 2, stop rod 5 is set in guide seat 3, positioning groove 52 on the stop rod 5, guide seat 3 is equipped with The directional screw 4, the inner end of the directional screw 4 is placed in the positioning groove 52 on the material retaining rod 5, and the upper section of the material retaining rod 5 is provided with a slowing slope 51, and the slowing slope 51 and the central axis of the material retaining rod 5 The included angle between them is 8°~15°, the ear seat 8 is fixed on the column 2, the lifting and shrinking rod of the cylinder 7 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com