Polyurethane cushion and production technique thereof

A production process and polyurethane technology, applied in other household appliances, household components, applications, etc., can solve the problems of dirty production environment, high operation requirements, and many process flows, and achieve less manual operation requirements, safe and convenient operation, and production technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

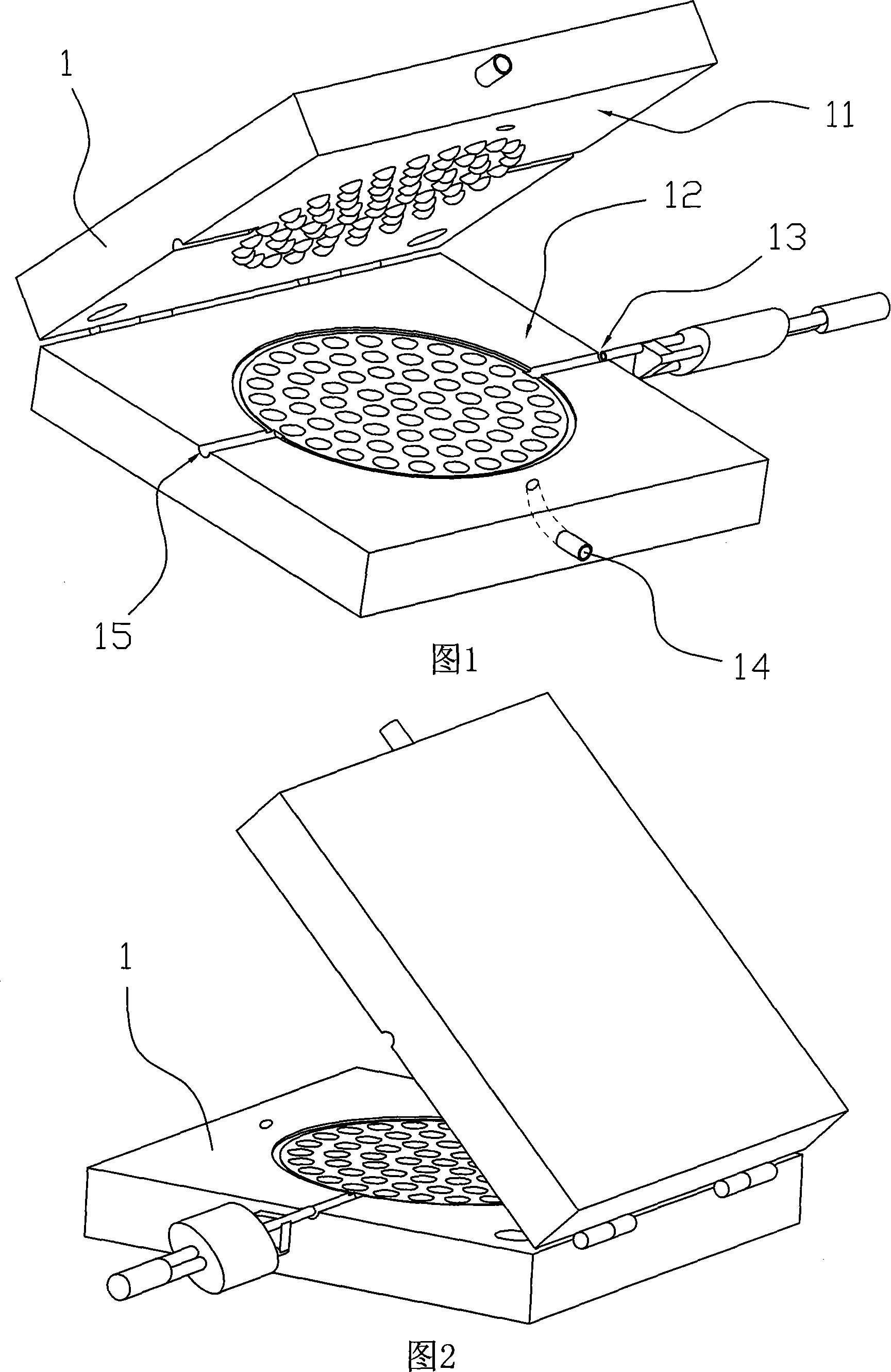

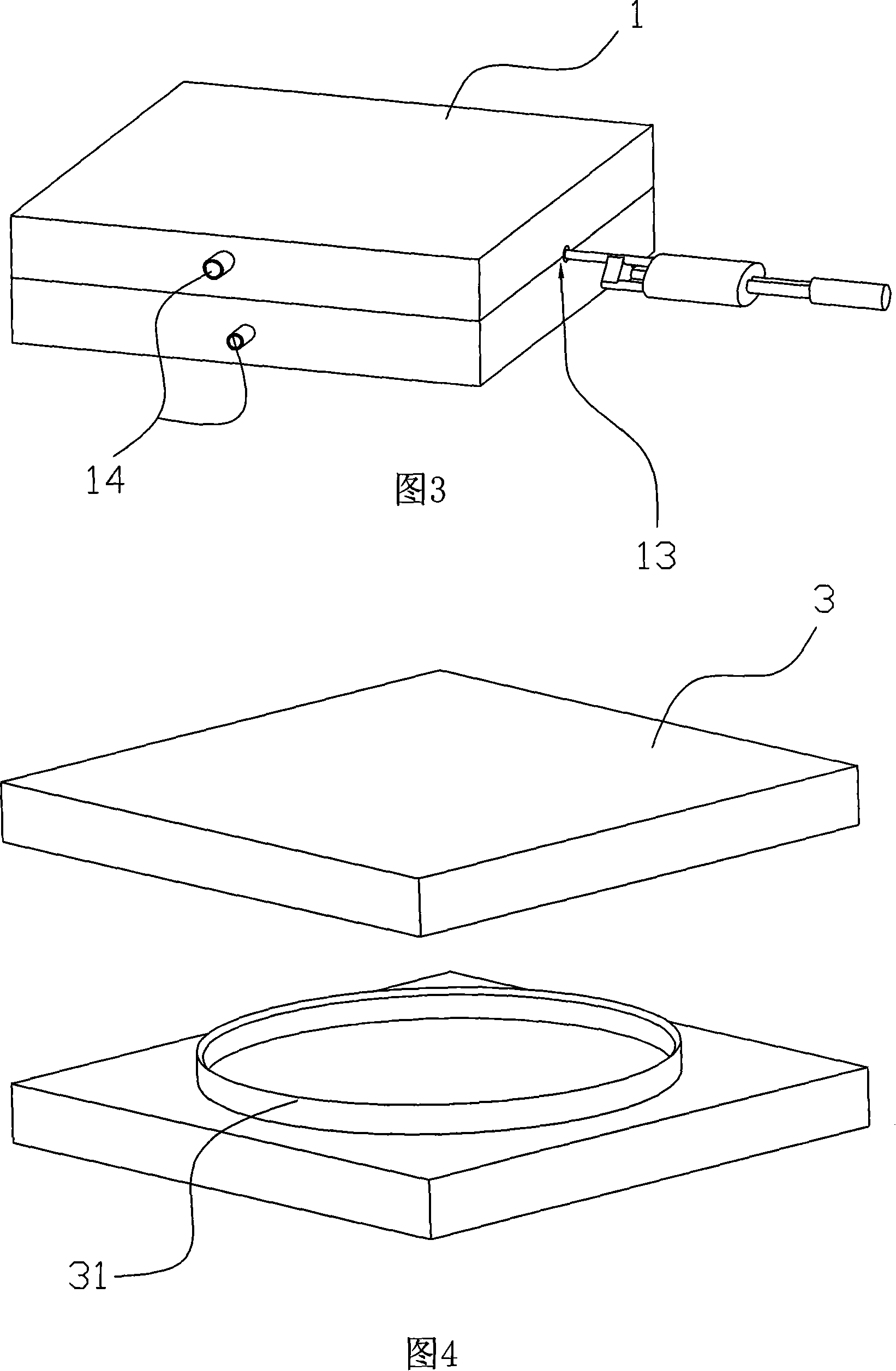

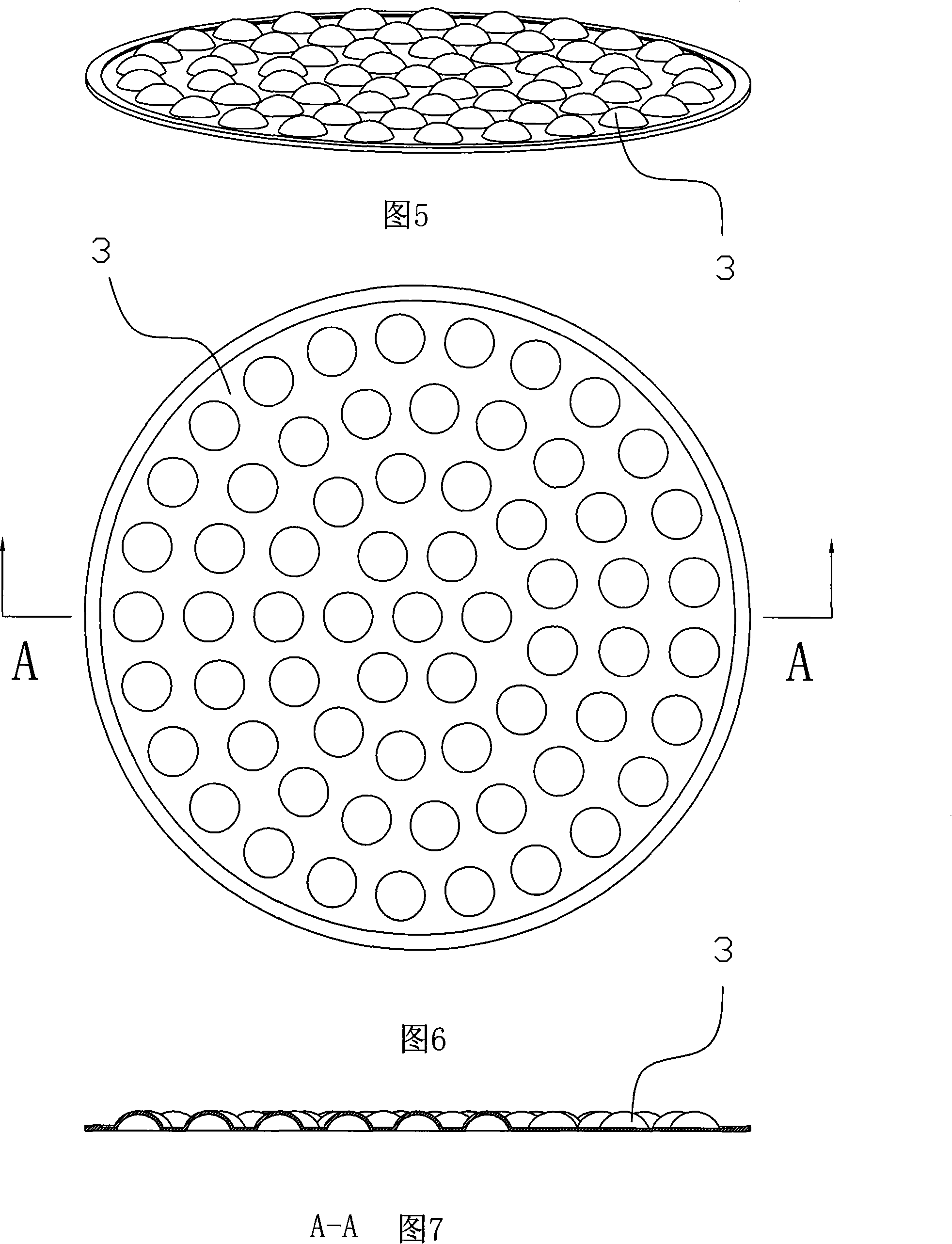

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0031] Implementation one, the polyurethane cushion of the present embodiment is mixed by following two parts formulas:

[0032] a, polyether polyol 40%, polyester polyol 55%, butylene glycol or / and ethylene glycol or / and propylene glycol neopentyl glycol or / and hexylene glycol or / and diethylene glycol or / and diethylene glycol Propylene glycol 4.5%, stannous octolate or / and dibutyltin dilaurate or / and bismuth isooctanoate 0.5%;

[0033] b. Polyether polyol 30%, polyester polyol or / and polycarbonate diol 19.6%, isocyanate 50%, adipoyl chloride or / and phosphoric acid or oleic acid 0.1%, butanediol or / and neopentyl diol Alcohol or / and hexylene glycol 0.3%, and the mixing ratio of a:b components is 3:2, and the above are percentages by weight. The above are percentages by weight.

[0034] The manufacturing process of the polyurethane cushion co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com