Method for preparing printed pattern PU/PVC artificial leather with printed pattern by dry method and PU/PVC artificial leather

A technology for printing patterns and manufacturing methods, applied in chemical instruments and methods, textiles and papermaking, fabric kneading/softening, etc., can solve the problems of increased production processes, pattern shedding, unnatural appearance of leather, etc., to simplify the production process. , the effect of reducing energy consumption and reducing staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

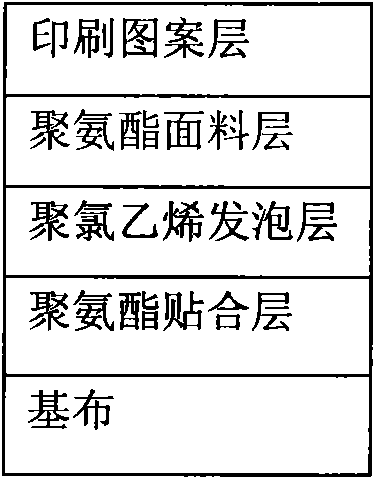

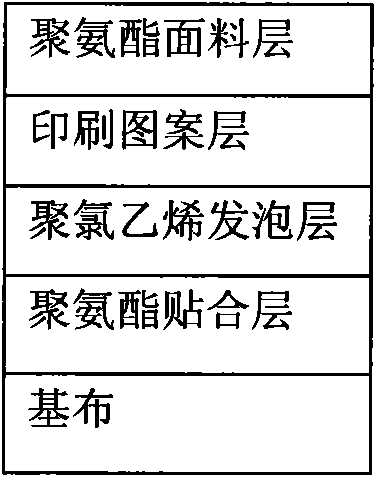

[0027] A kind of printing pattern PU / PVC dry-process artificial leather manufacturing method, 1, buy the release paper of market best-selling grain, select solvent-based polyurethane fabric resin, polyurethane bonding material, polyurethane printing material, polyvinyl chloride foam paste resin for use, and Suitable base cloth. The viscosity of the polyurethane fabric resin is 100000-200000cps, the content of non-volatile matter is 25%-35%, the viscosity of polyurethane printing resin is 500-3000cps, the content of non-volatile matter is 20%-50%, the polyurethane adhesive resin The viscosity is 60000-120000cps, and the content of non-volatile matter is 35%-50%. Polyvinyl chloride resin is an emulsion polymer resin with a K value of 65-75.

[0028] 2. Polyurethane coloring coating. The polyurethane PU is diluted to a dilution material with a viscosity value of 1300-1500 cps by using the dilution solvent dimethylformamide DMF, toluene TOL and butanone MEK, and the weight ratio...

Embodiment 2

[0034] The remaining steps of the printed pattern PU / PVC dry-process artificial leather manufacturing method of this embodiment are the same as in Example 1, which is to add a kneading process after the release: the obtained semi-finished product is placed in a kneading machine with a temperature of 50 ° C, kneaded After 40 hours of tattooing, the kneading process is completed.

[0035] The parts not described in this embodiment are the same as those in Embodiment 1.

Embodiment 3

[0037] This embodiment is basically the same as Example 2, except that the obtained semi-finished product is placed in a kneading machine with a temperature of 70° C., kneaded for 30 hours, and the kneading procedure is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com