Method for preparing printed pattern PU/PVC artificial leather with printed pattern by dry method and PU/PVC artificial leather

A technology for printing patterns and manufacturing methods, applied in chemical instruments and methods, textiles and papermaking, fabric kneading/softening treatment, etc., can solve the problem of affecting the texture of PU/PVC artificial leather, affecting the production rate of products, and the unnatural look and feel of leather and other problems, to achieve natural look and feel, unique printing effect, and reduce the effect of staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

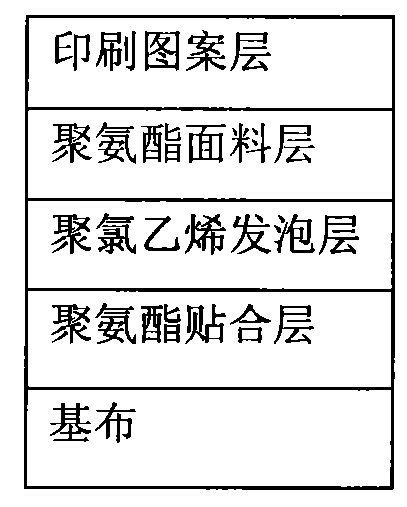

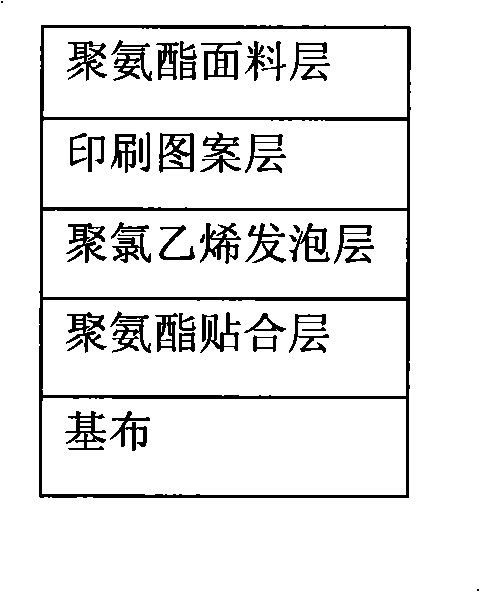

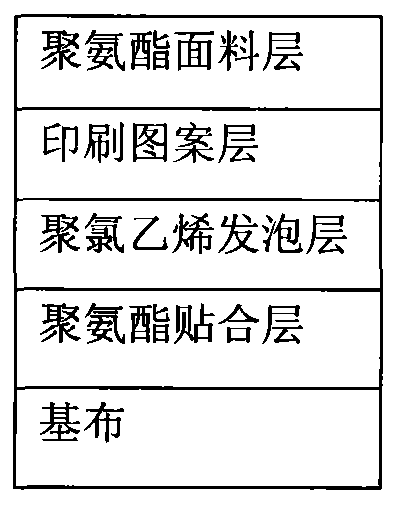

Image

Examples

Embodiment 1

[0027] A printing pattern PU / PVC dry-process artificial leather manufacturing method: 1. Buy the release paper with the best-selling texture in the market, using solvent-based polyurethane fabric resin, polyurethane laminating material, polyurethane printing material, polyvinyl chloride foam paste resin, and Suitable base cloth. The resin viscosity of the polyurethane fabric is 100000~200,000 cps, the content of non-volatile matter is 25%-35%, the viscosity of polyurethane printing resin is 500-3000 cps, and the content of non-volatile matter is 20%-50%. Polyurethane adhesive resin The viscosity is 60,000 to 120,000 cps, and the non-volatile content is 35% to 50%. The polyvinyl chloride resin is an emulsion polymerization resin with a K value of 65 to 75.

[0028] 2. Polyurethane color coating. Using the diluent solvents dimethylformamide DMF, toluene TOL and methyl ethyl ketone MEK, the polyurethane PU is diluted to a diluent with a viscosity of 1300-1500 cps, and the weight r...

Embodiment 2

[0034] The rest of the steps in the manufacturing method of the printed pattern PU / PVC dry artificial leather of this embodiment are the same as in embodiment 1, which is to add the kneading process after release: the obtained semi-finished product is placed in a kneading machine at a temperature of 50°C and kneaded After 40 hours of tattooing, the rubbing procedure is completed.

[0035] The parts not described in this embodiment are the same as the first embodiment.

Embodiment 3

[0037] This embodiment is basically the same as Embodiment 2, except that the obtained semi-finished product is placed in a kneading machine at a temperature of 70° C., and kneading the kneading process for 30 hours is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com