Ultrahigh speed real-time three-dimensional measuring device and method

A real-time three-dimensional, visual measurement technology, applied in the field of visual measurement, can solve problems such as inability to realize three-dimensional measurement, and achieve the effect of high update rate and high image data volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

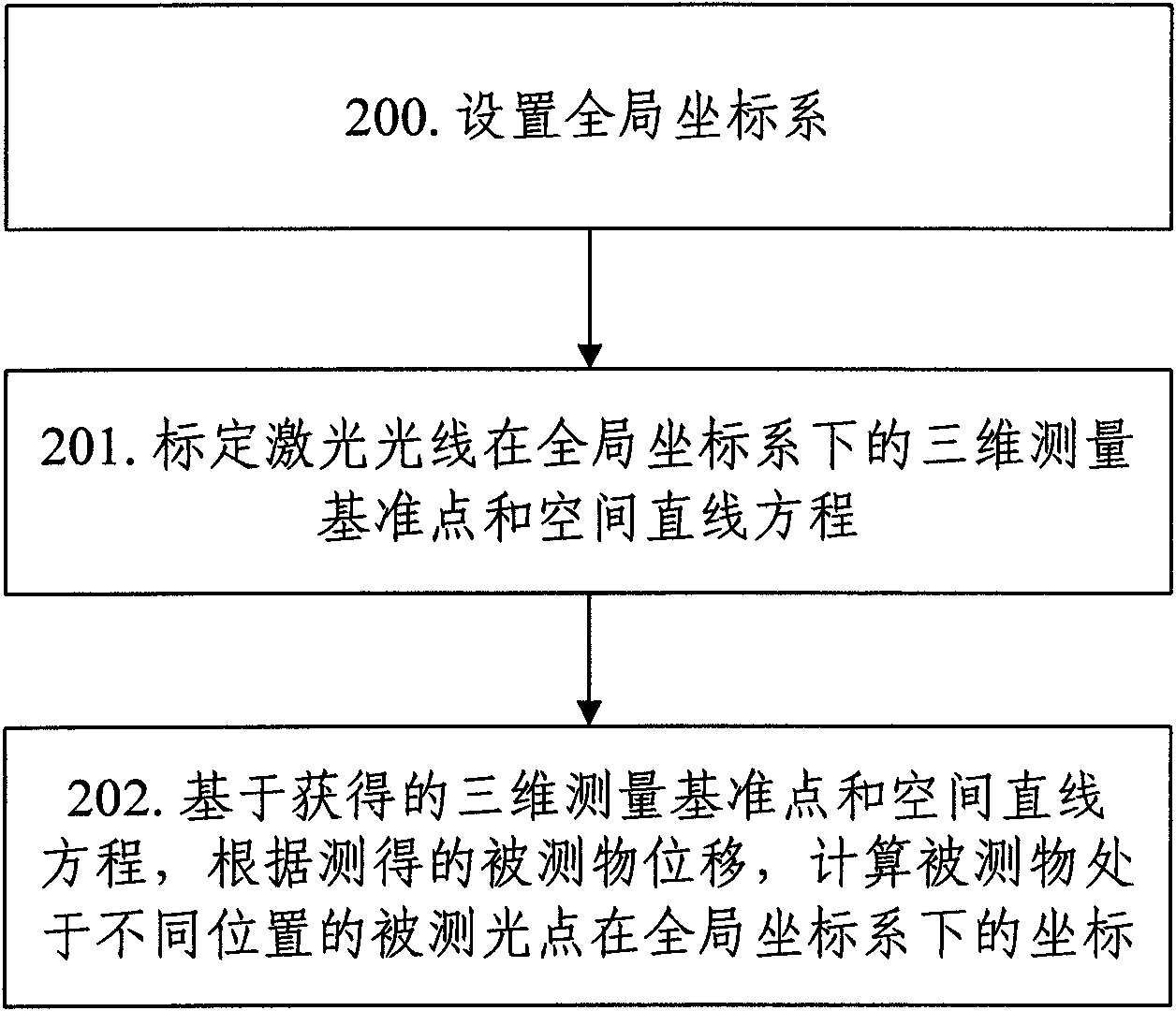

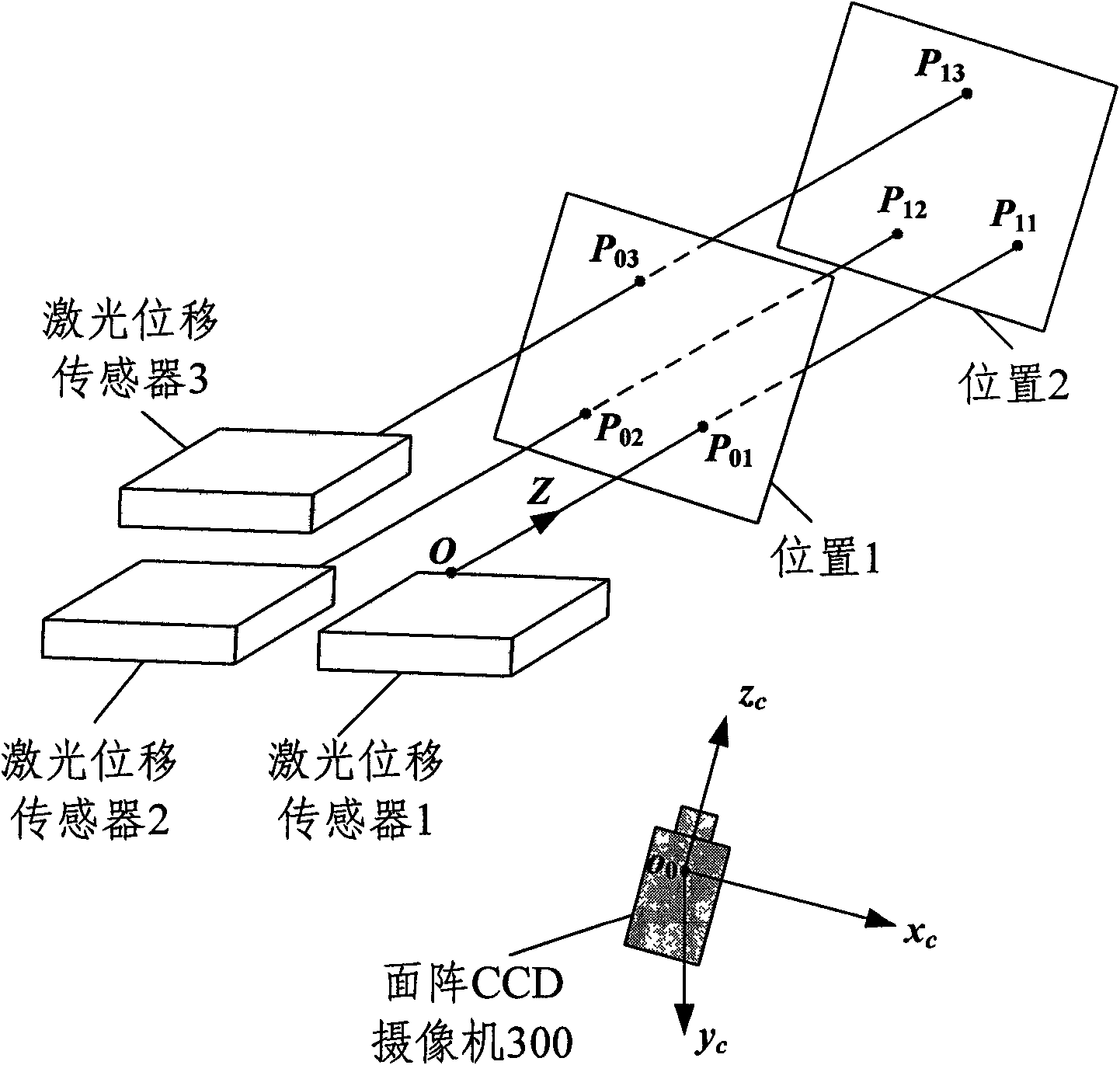

[0028] The basic idea of the present invention is: use the laser displacement sensor, the area array camera and the planar target to obtain the three-dimensional measurement reference point and the space linear equation, based on the obtained measurement reference point and the space linear equation, according to the measured displacement of the measured object, calculate The coordinates of the measured light points in different positions of the measured object in the global coordinate system, so as to complete the ultra-high-speed real-time three-dimensional visual measurement of the measured object.

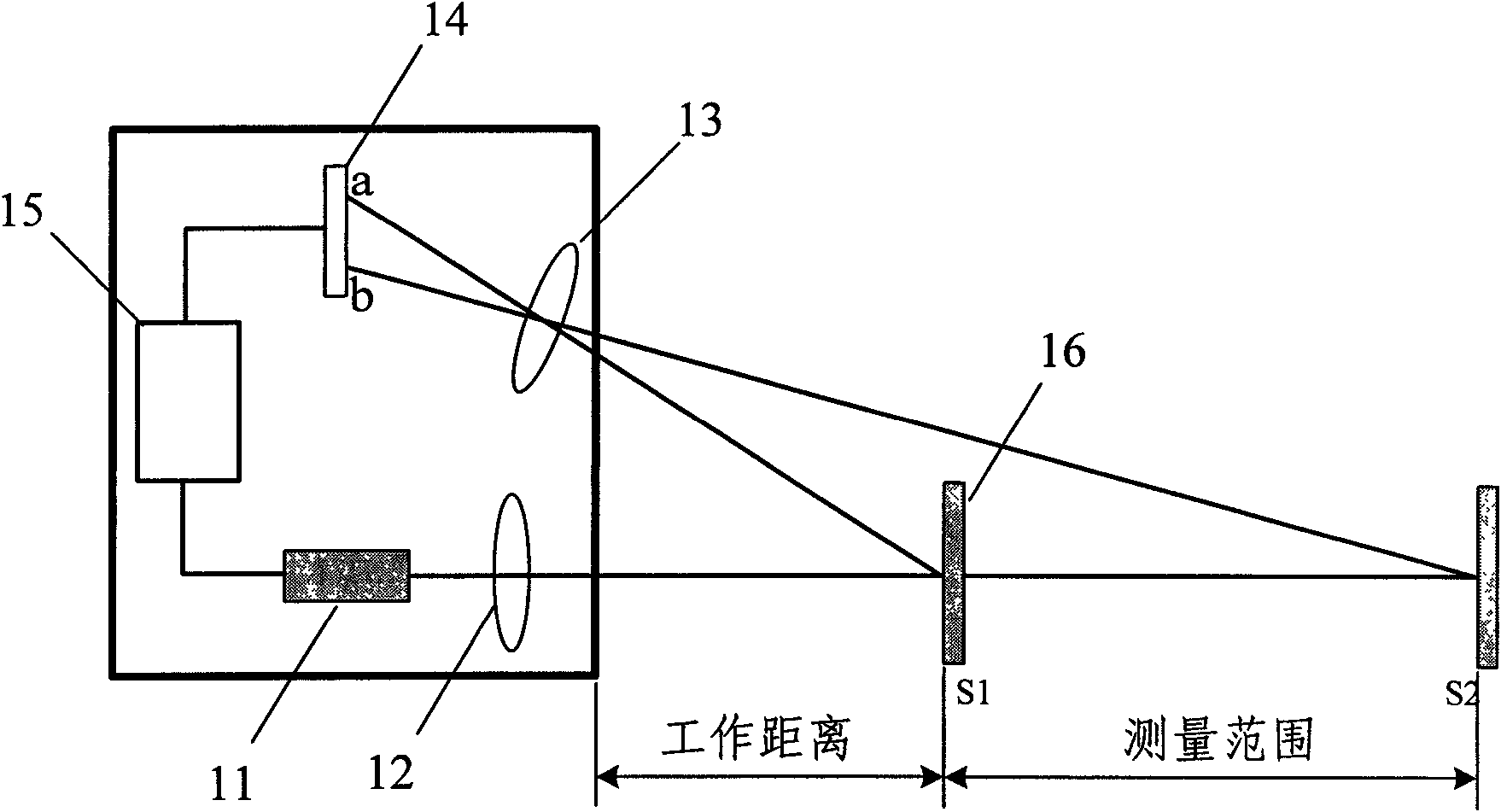

[0029] The ultra-high-speed real-time three-dimensional visual measurement device of the present invention includes: an area array camera, one or more laser displacement sensors; wherein,

[0030] An area array camera is used to take target images and obtain the transformation relationship between the target coordinate system and the camera coordinate system;

[0031] The las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com