Automotive anti-lock braking and braking energy feedback integration control hardware-in-the-loop test bed

A braking energy feedback, integrated control technology, applied in vehicle testing, machine/structural component testing, measuring devices, etc., to achieve the effect of improving execution efficiency, high repeatability, and shortening development time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the embodiments.

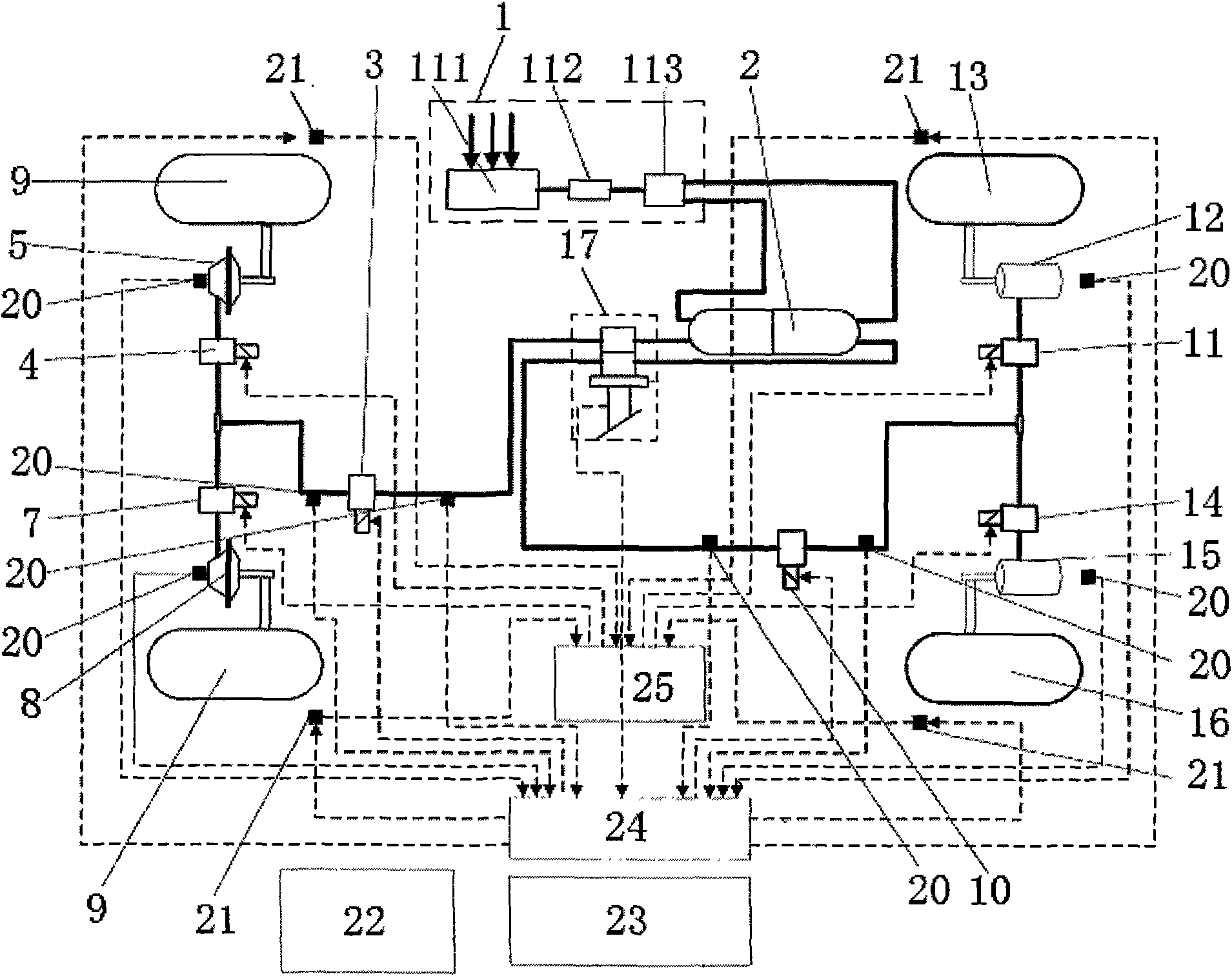

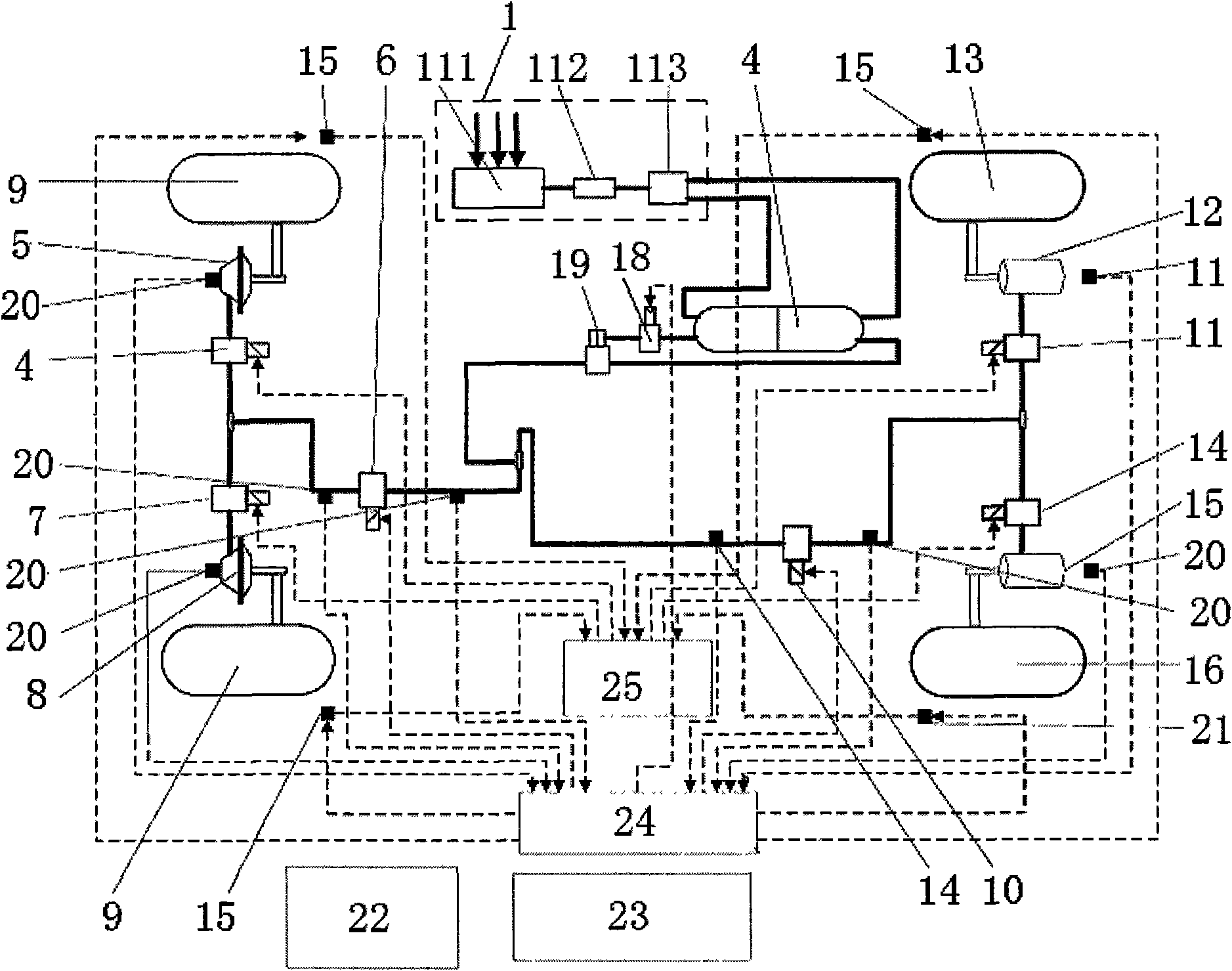

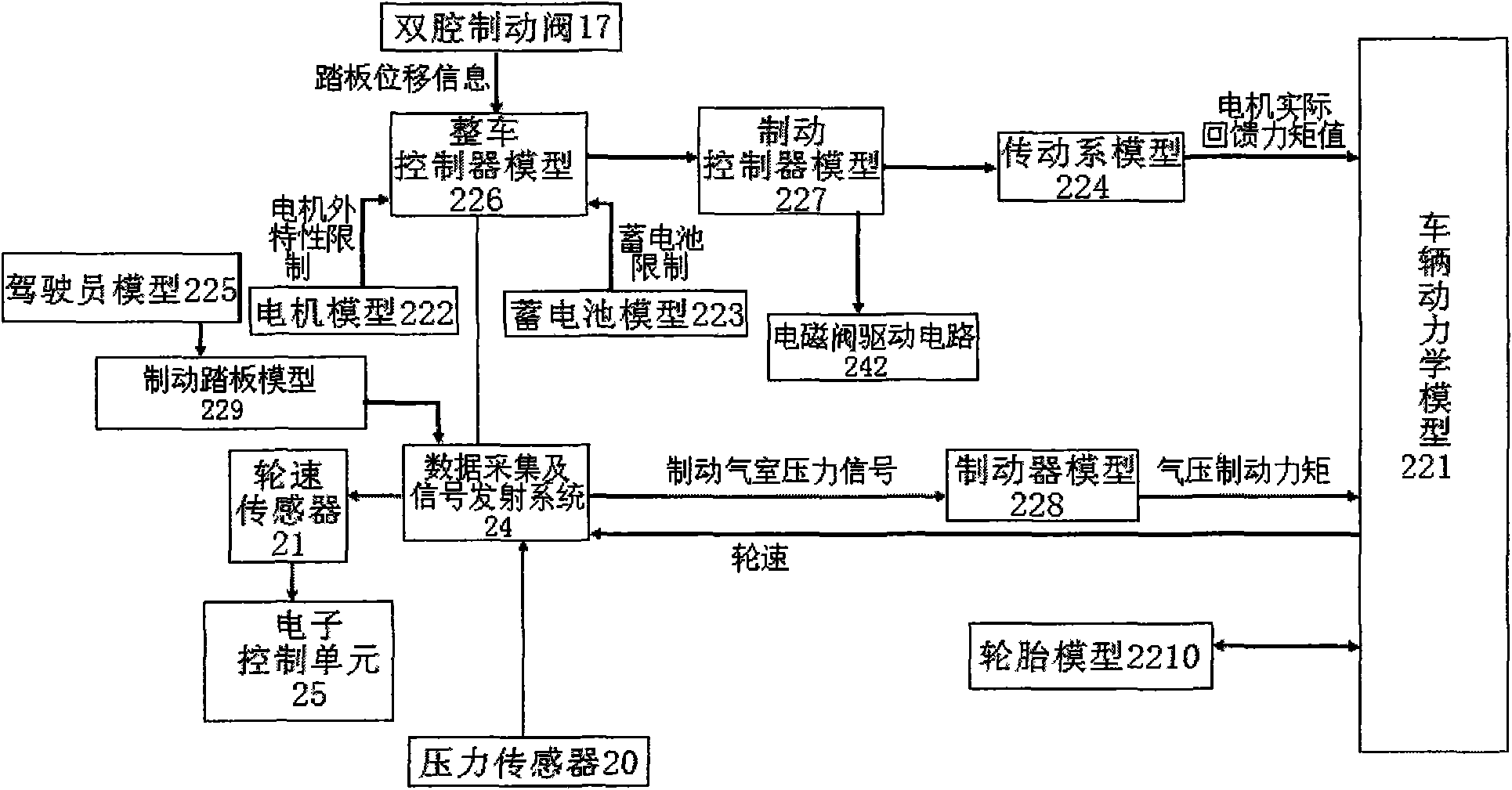

[0016] The present invention includes a front brake air circuit, a rear brake air circuit, a brake control unit and a test bench, each device in the front brake air circuit, the rear brake air circuit, and the brake control unit is related to the actual The devices used in the city bus are the same, and they are all fixed on the test bench by brackets. The brake control unit controls the brakes of the front and rear brake air circuits according to the brake commands input by the external tester, so as to complete the hardware-in-the-loop simulation experiment of the brake anti-lock brake and brake energy feedback of the hybrid city bus .

[0017] Such as figure 1 As shown, the front brake air circuit includes an air source 1, an air reservoir 2 and a front brake feedback regulating valve 3 connected in series through the pipeline, and the outlet end of the front brake feedba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com