Polarizing film, polarizer and manufacturing method thereof

A manufacturing method and technology of polarizers, applied in the field of polarizers, can solve problems such as the decline in consumer trust in products, separation, etc., and achieve the effects of preventing easy detachment, improving adhesion, and improving product durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

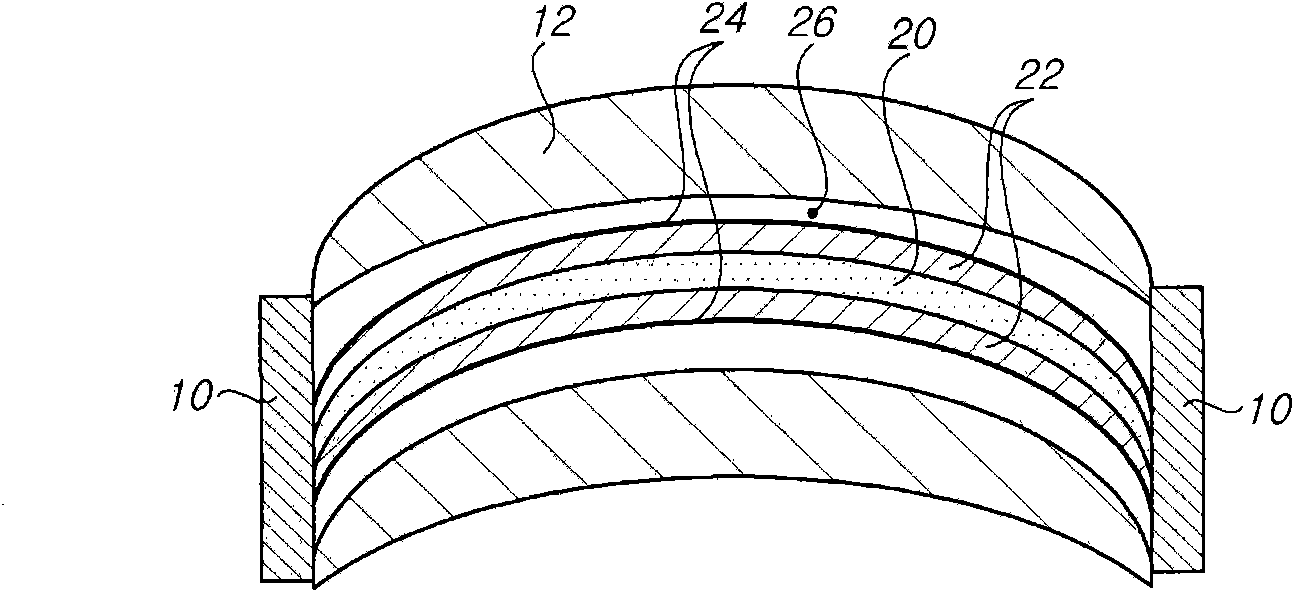

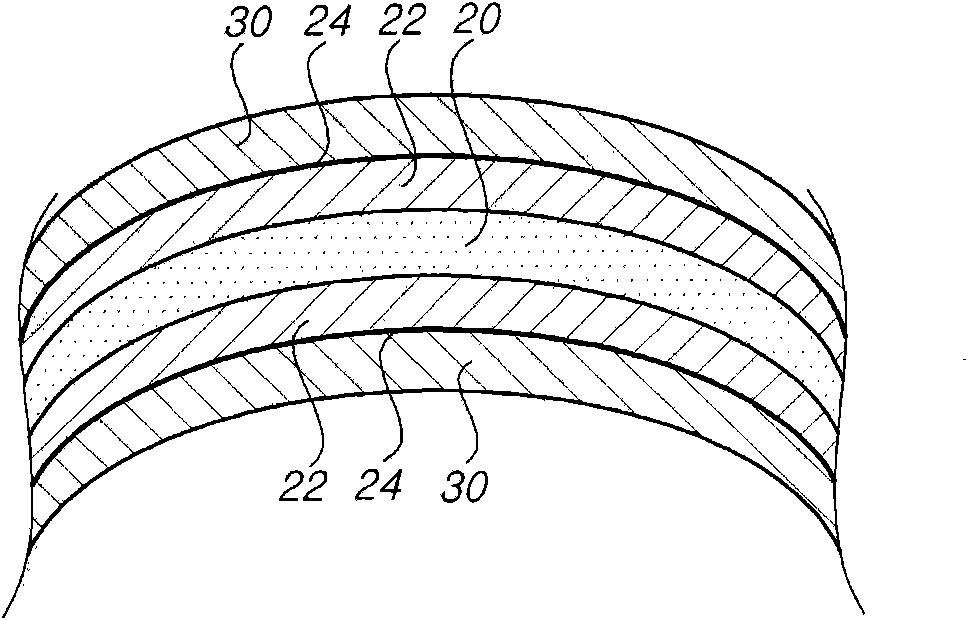

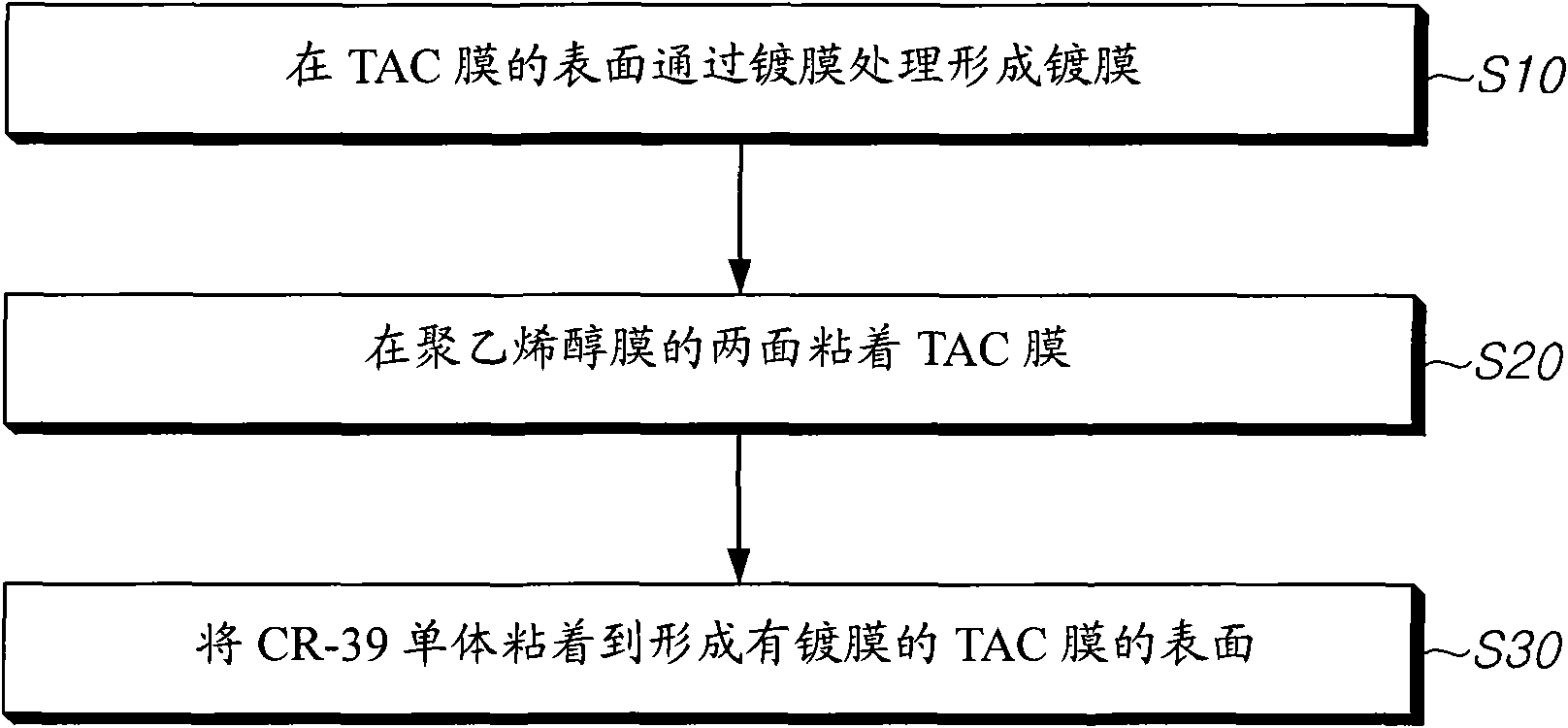

[0022] figure 1 It is a structural diagram showing the manufacturing process of the polarizer of the present invention, figure 2 is a configuration diagram showing the configuration of a preferred embodiment of the polarizer according to the present invention.

[0023] According to the above illustration, when the description is centered on the manufacturing process of the polarizer, there is a spacer 10 that functions as a mold for manufacturing the polarizer. In addition, molded bodies 12 serving as molds together with the spacers 10 are respectively provided on the upper and lower portions of the spacers 10 . Furthermore, an adhesive polyvinyl alcohol film 20 and a TAC film are located between the above-mentioned molded body 12 .

[0024] The production process of the above-mentioned polyvinyl alcohol film 20 is briefly described....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com