Intelligent activating method for accumulator

A battery and battery pack technology, applied in secondary battery charging/discharging, secondary battery repair/maintenance, etc., can solve problems such as inability to guarantee accuracy, lack of scientific basis for manual judgment, and high professional skills requirements for operators. The effect of reducing professional skill requirements, reducing activation time, and improving activation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

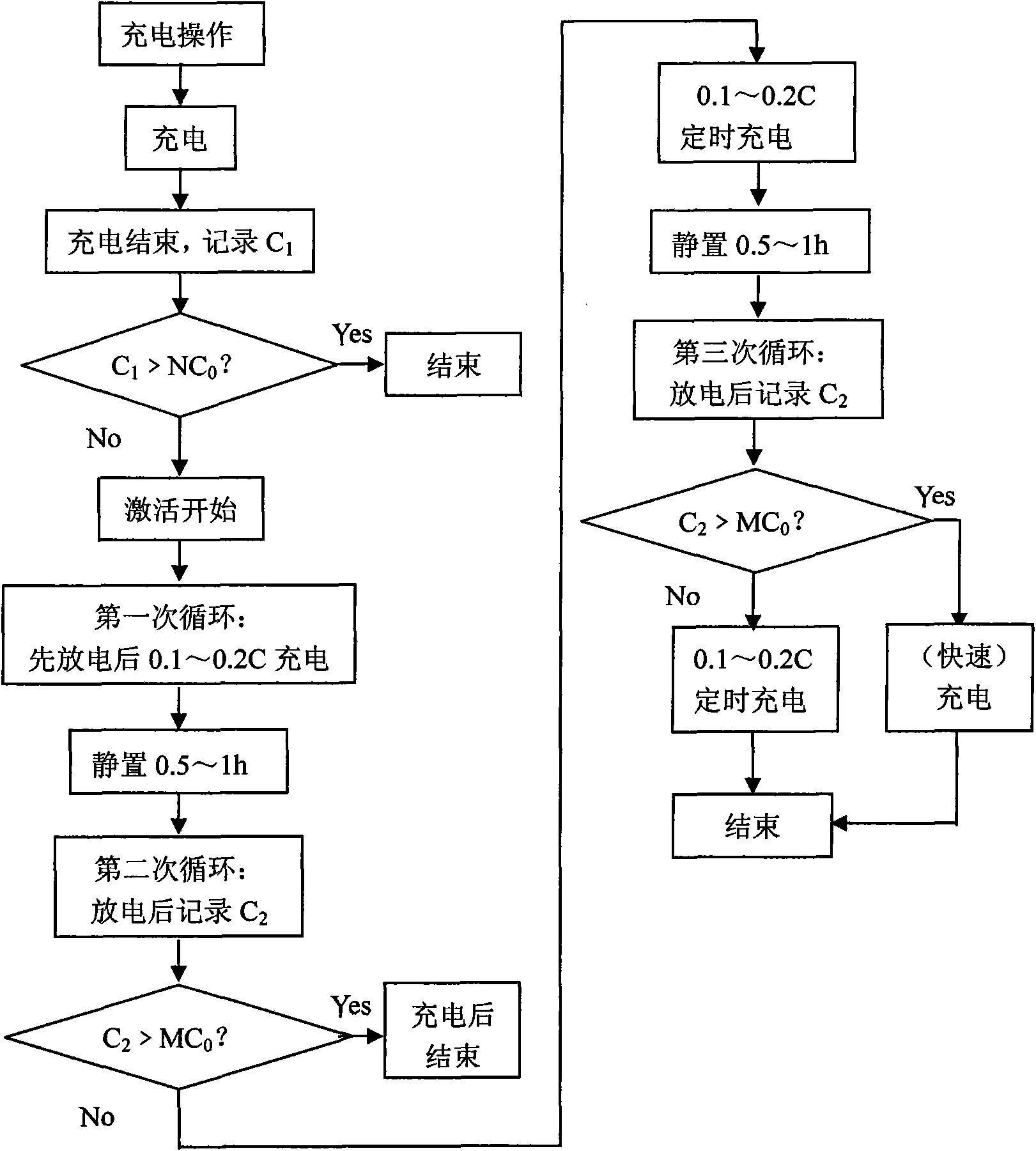

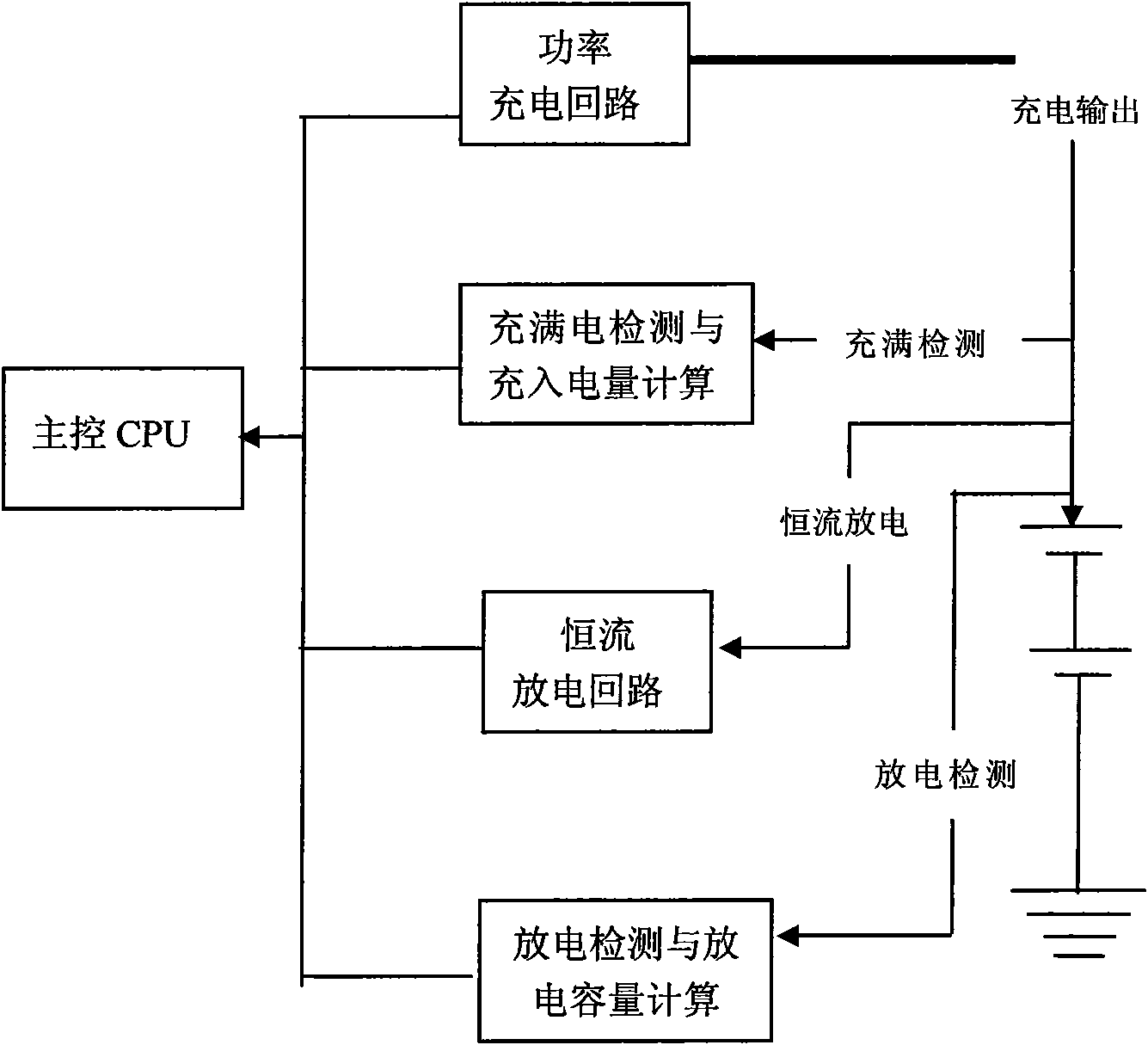

Embodiment 1

[0034] Embodiment 1: Input the type data of a battery pack (model 20GNYG4.5) to be activated to the main control CPU of the charger, and perform constant current at a rate of 0.5C for the battery pack (model 20GNYG4.5) to be activated Voltage-limited charging operation (because this type of battery is prone to memory effect, the remaining power has been discharged before charging), during the charging process, the voltage negative incremental method is used to detect its charging state, when the charging is carried out for 1 hour, the battery terminal A voltage drop of 100 millivolts gradually appeared, indicating that the battery was fully charged this time. At this time, the main control CPU records the number of ampere hours C used for charging 1 =0.5C×4.5×1=2.25Ah, equal to the nominal capacity C of the battery 0 = 0.5 times of 4.5Ah, the battery needs to be activated to restore its capacity, and the main control CPU controls the battery to automatically enter the activat...

Embodiment 2

[0037] Embodiment 2: Input the type data of a certain type of equipment battery pack (model 20GNYG4.5) to be activated to the main control CPU of the charger, and perform constant current at a rate of 0.2C for the battery pack to be activated (model 20GNYG4.5) Voltage-limited charging operation (because this type of battery is prone to memory effect, so the remaining power has been discharged before charging), the charging state is detected by the voltage negative increment method during the charging process, and the battery terminal is charged after 3.5 hours. A voltage drop of 100 millivolts gradually appeared, indicating that the battery was fully charged this time. At this time, the main control CPU records the number of ampere hours C used for charging 1 =0.2C×4.5×3.5=3.15Ah, equal to the nominal capacity C of the battery 0 = 0.7 times of 4.5Ah, the battery needs to be activated to restore its capacity, and the main control CPU controls the battery to automatically enter...

Embodiment 3

[0040] Embodiment 3: Input the type data of a battery pack (model 20QNY7.0) to be activated to the main control CPU of the charger, and perform constant current at a rate of 0.5C for the battery pack (model 20QNY7.0) to be activated Voltage-limited charging operation (assuming that the remaining power has been discharged before charging), during the charging process, the voltage zero-increment method is used to detect the charging state. When the charging is carried out for 1 hour, the battery terminal voltage does not rise and has a downward trend. Indicates that the battery is fully charged this time. The main control CPU records the number of ampere hours C used for charging 1 =0.5C×7.0×1h=3.5Ah, equal to the nominal capacity C of the battery 0 = 0.7 times (less than 0.8 times) of 7.0Ah, the main control CPU automatically controls the battery to enter the active working mode to restore its capacity. The specific activation process is as follows:

[0041] The first cycle:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com