Needle motion

A movement mechanism and knitting needle technology, which is applied in the directions of knitting, weft knitting, and weft knitting circular knitting machines with separate action needles, etc. structure, the effect of speeding up the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

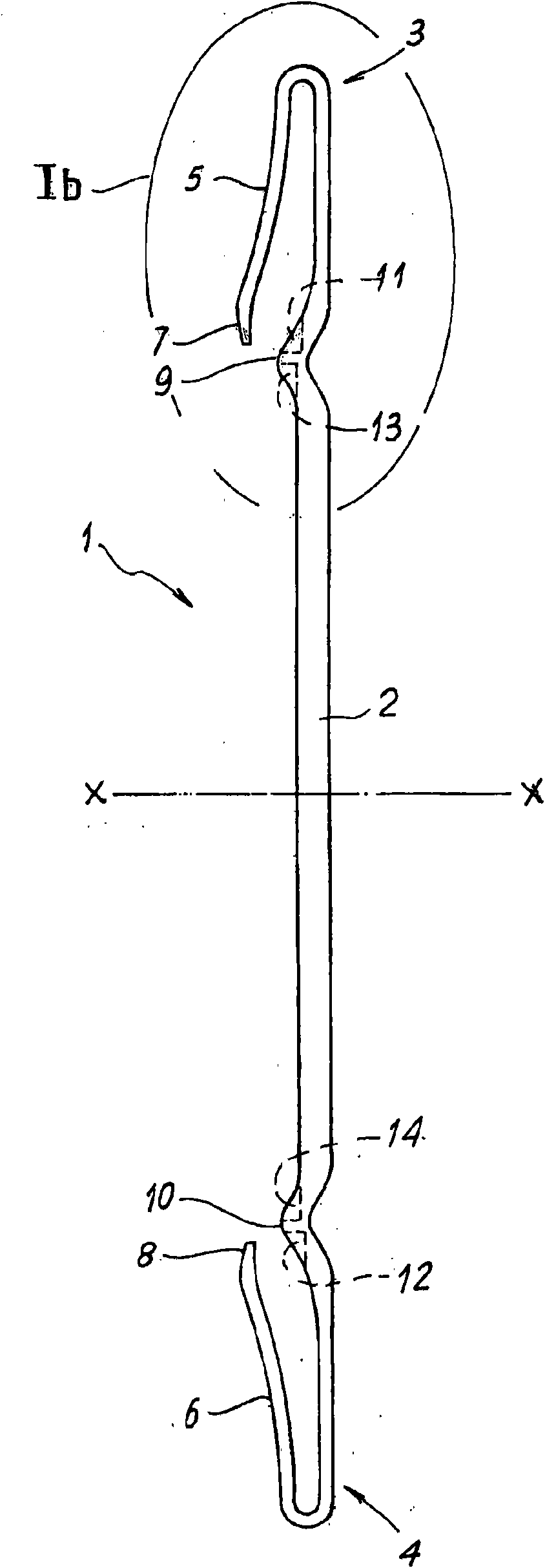

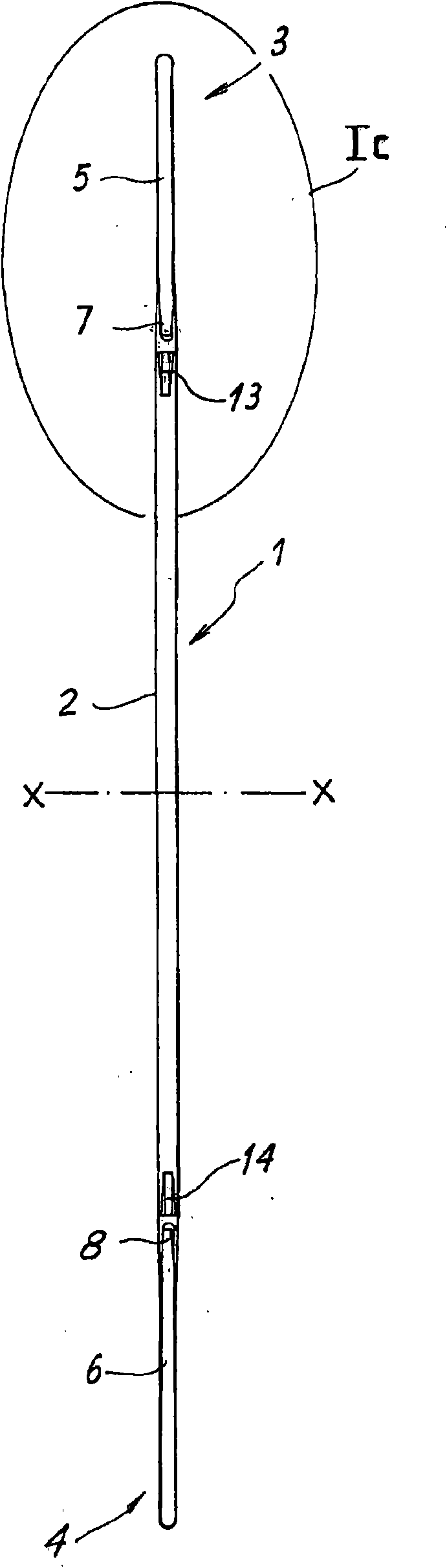

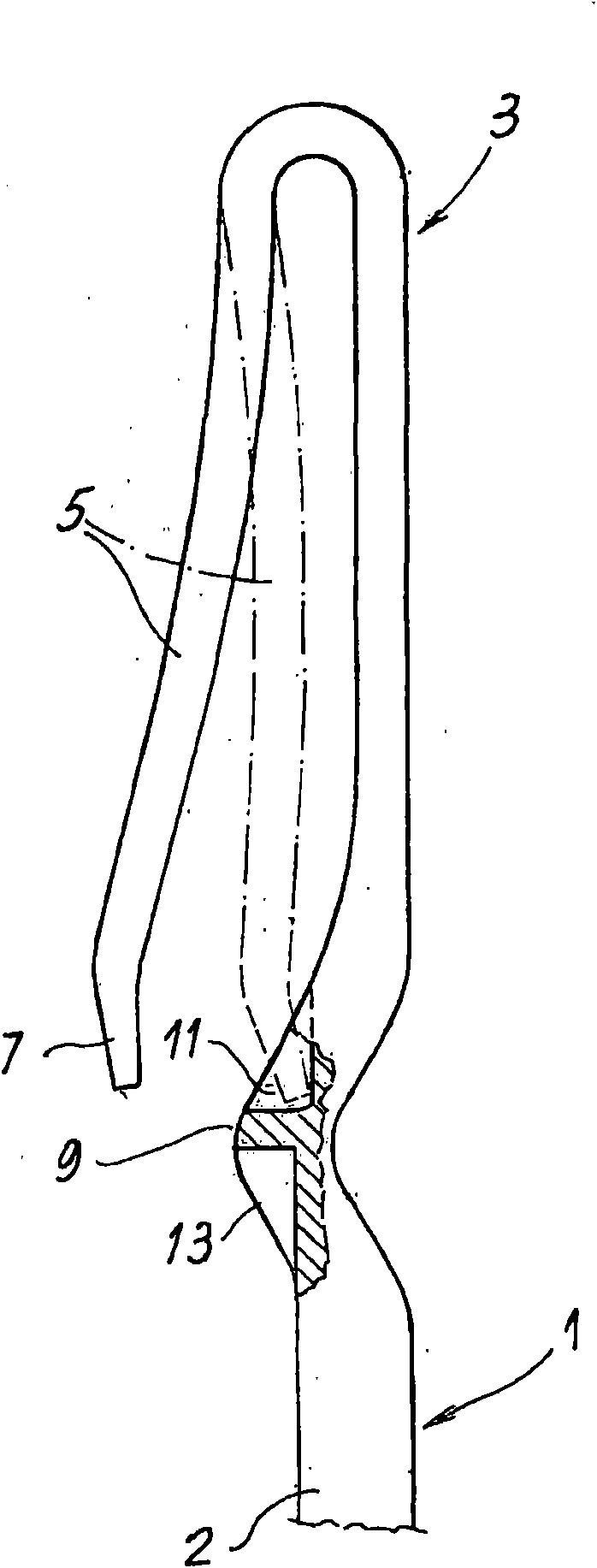

[0035] like figure 1 A needle of the invention is shown, which can be used in the needle kinematic mechanism of the invention. The knitting needle 1 comprises a needle shaft 2 with oppositely arranged needle heads each comprising a respective knitting hook or hook 3 , 4 . Each hook or needle hook is basically shaped like a so-called "spring crochet hook" or "crochet hook" or simply a "pogo pin". Each hook or needle hook extends from an elastic hook or called elastic hook 5 , 6 to a tip 7 , 8 . This knitting needle 1 thus becomes a so-called "spring crochet needle" or "crochet needle", however, unlike the crochet needles of the prior art, it is double, ie provided with hooks at both ends of the shank. The needle may be made from a piece of spring steel forming the shaft and the two long end hooks or hooks 3,4.

[0036] On the needle shaft 2 of the knitting needle 1, a needle shaft bend 9, 10 is provided where each tip 7, 8 of the elastic hook 5, 6 reaches when the hook is cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com