Small-sized automatic undulator and processing method

A corrugated machine and corrugated technology, applied in the direction of metal processing equipment, manufacturing tools, shearing machine accessories, etc., can solve the problem of failure to find mechanical products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

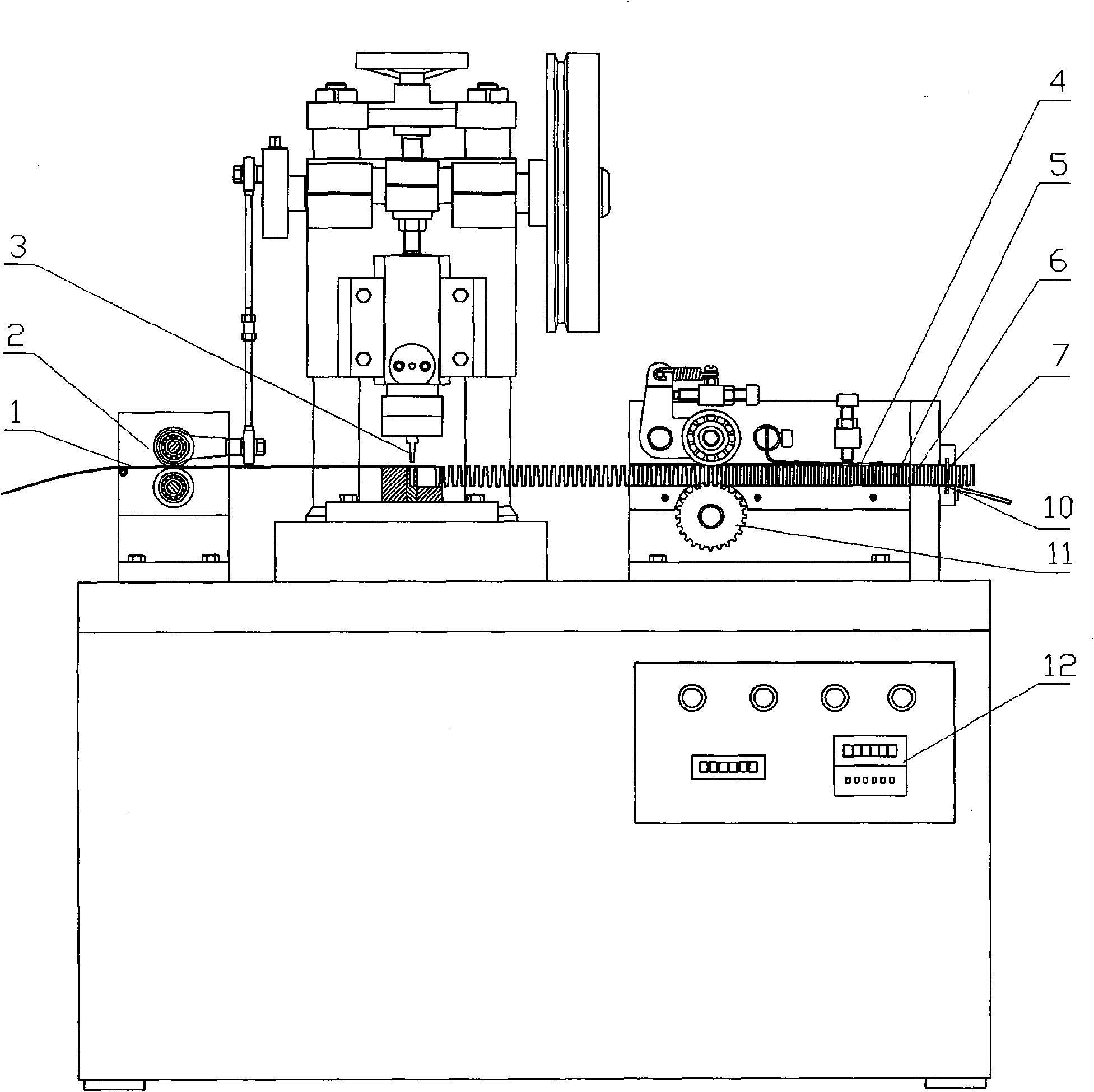

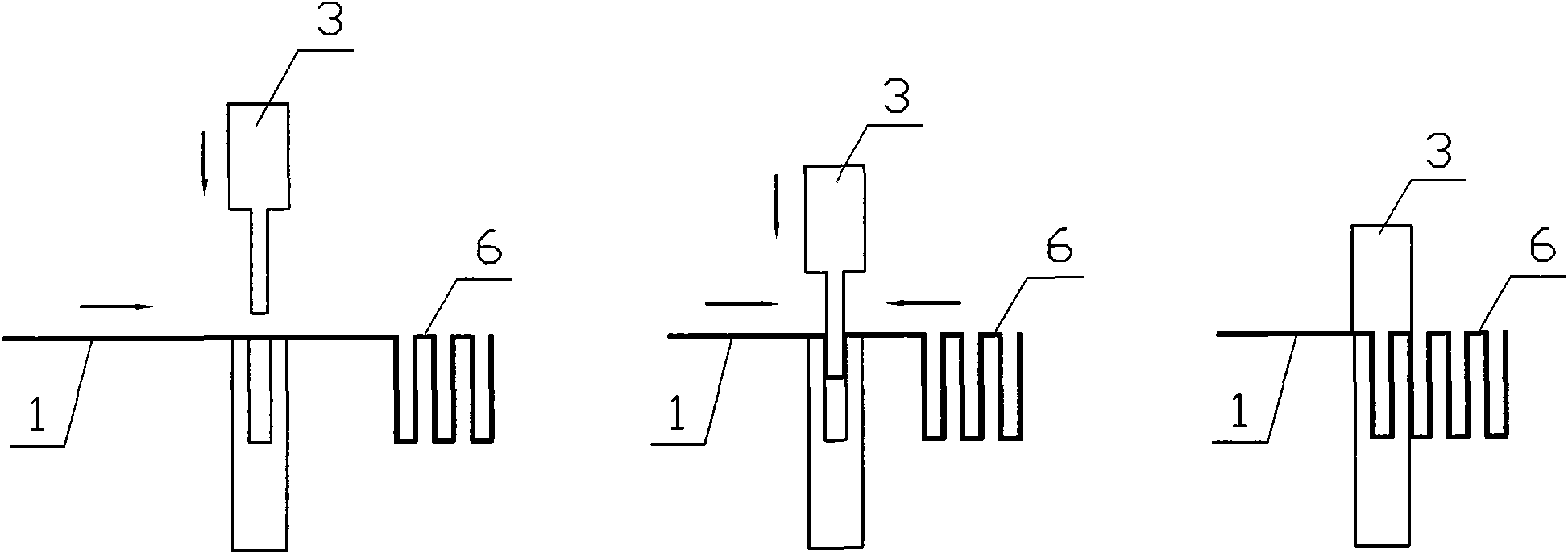

[0028] Implementation method: the metal strip enters the stamping area through the feeder 2, and is stamped by a die to form a corrugated shape;

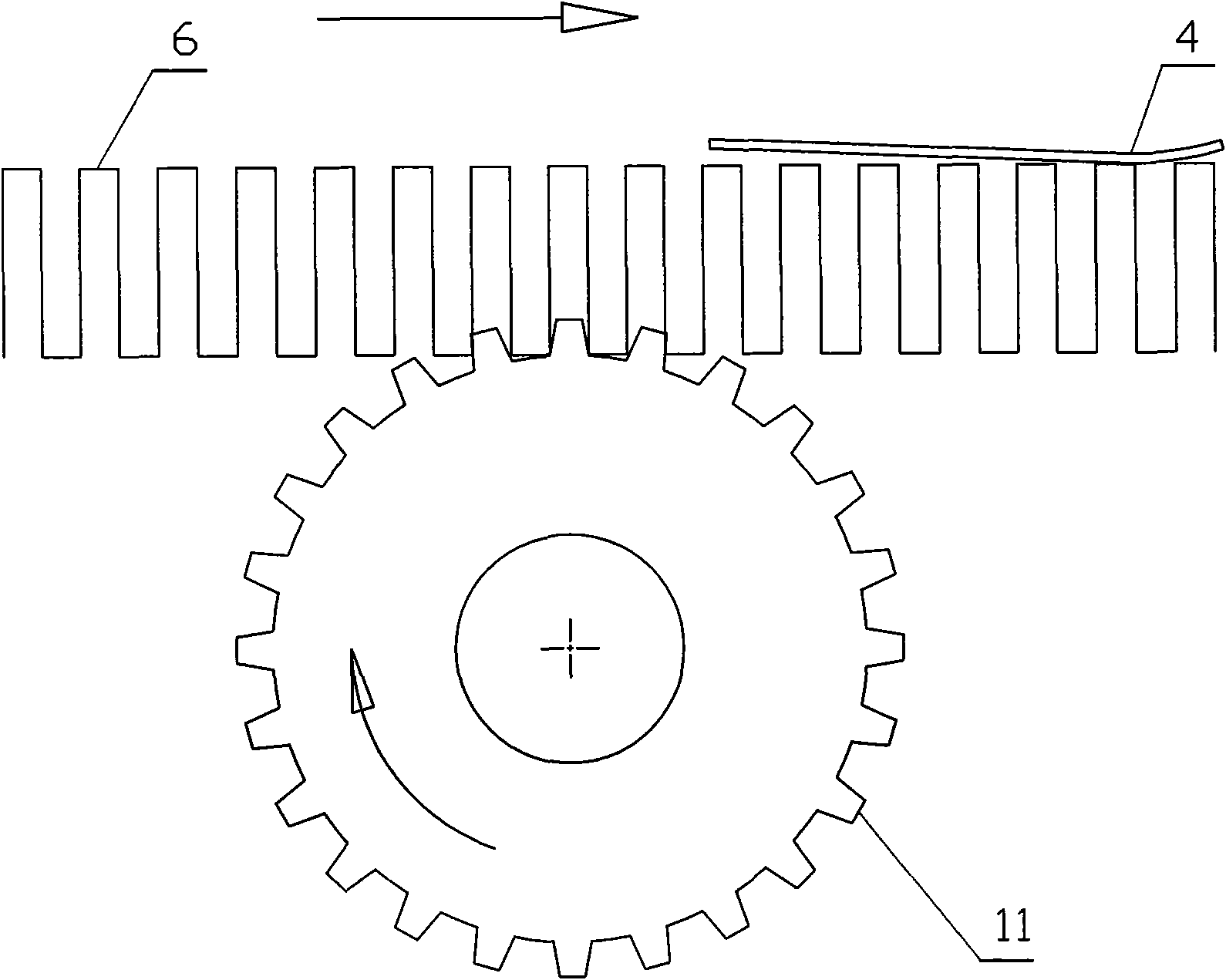

[0029] The 6 formed corrugated workpieces enter the wave pitch compression zone through the guide groove, and move forward under the force of the corrugated meshing gear 11 . Use the adjustable pressure platen 4 to apply friction to the 6 corrugated workpieces, so that the corrugated workpieces 6 will be resisted to advance, forming a force opposite to the advancing direction of the corrugated meshing gear 11, and the wave distance of the 6 corrugated workpieces will be compressed under the force, and the adjustment The pressing plate pressure 4 can control the compression degree of the wave pitch of the corrugated workpiece 6;

[0030]The 6 corrugated workpieces enter the cut-off area through the guide groove, the sensor 5 sends a signal to the counter 12, and the cut-off action is triggered by the preset value. The positioning fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com