Process for manufacturing carbon/carbon composite material with needling structure

A carbon composite material and manufacturing process technology, applied in the field of carbon/carbon composite material manufacturing process, can solve the problems of low carbon fiber strength, large shrinkage, troublesome size change, etc., and achieve the effect of improving material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

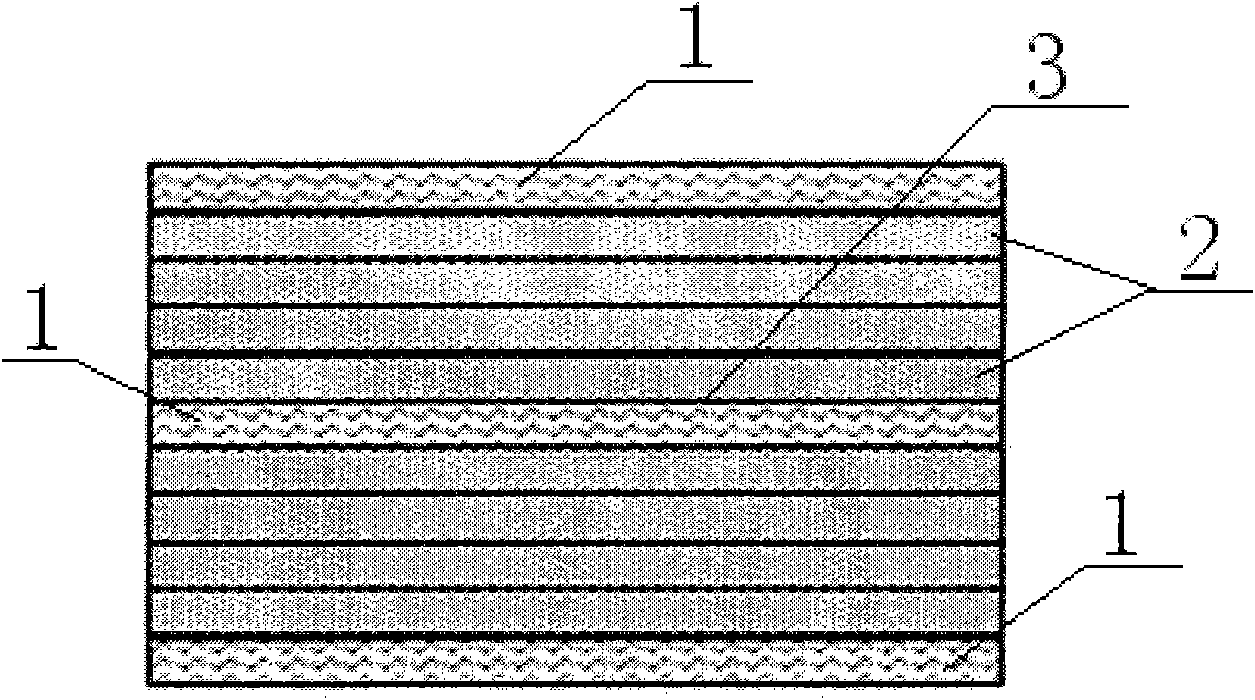

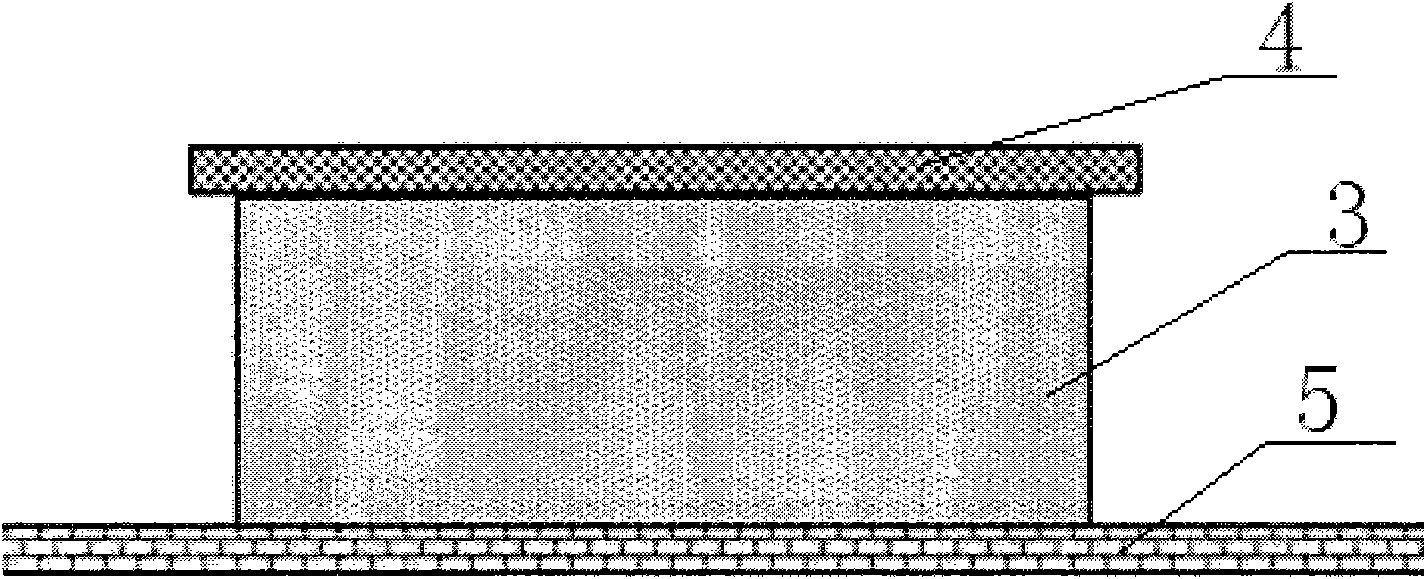

[0017] Aiming at the problem that the size and strength of the pre-oxidized silk material are difficult to control, the present invention invents a kind of pre-oxidized silk fiber felt mixed with chopped carbon fiber felt in a certain proportion, wherein the pre-oxidized silk felt accounts for 80% by weight, and the carbon fiber Felt accounts for 20% by weight. The preform is formed by needle punching, and the preform is carbonized under the new carbonization process system to realize the control of the material size and the improvement of the material strength. The advantage of this manufacturing process is that through the fine control of the carbonization process, the relationship between the shrinkage rate and the carbonization process parameters after the pre-oxidized silk felt and carbon fiber felt are mixed in a certain proportion is mastered, and the content of the carbon fiber felt is controlled. It can limit the shrinkage of the pre-oxidized wire during the carbonizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com