Method for reinforcing water-bearing stratum of floor of coal seam and protecting water-bearing stratum during reinforcement

A coal seam floor and water-resisting layer technology, which is applied in earthwork drilling, shaft lining, tunnel lining, etc., can solve problems such as coal seam floor water inrush, increased grouting pressure, and large grouting pressure, achieving good results and solving problems Forced to stop production, the effect is significant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

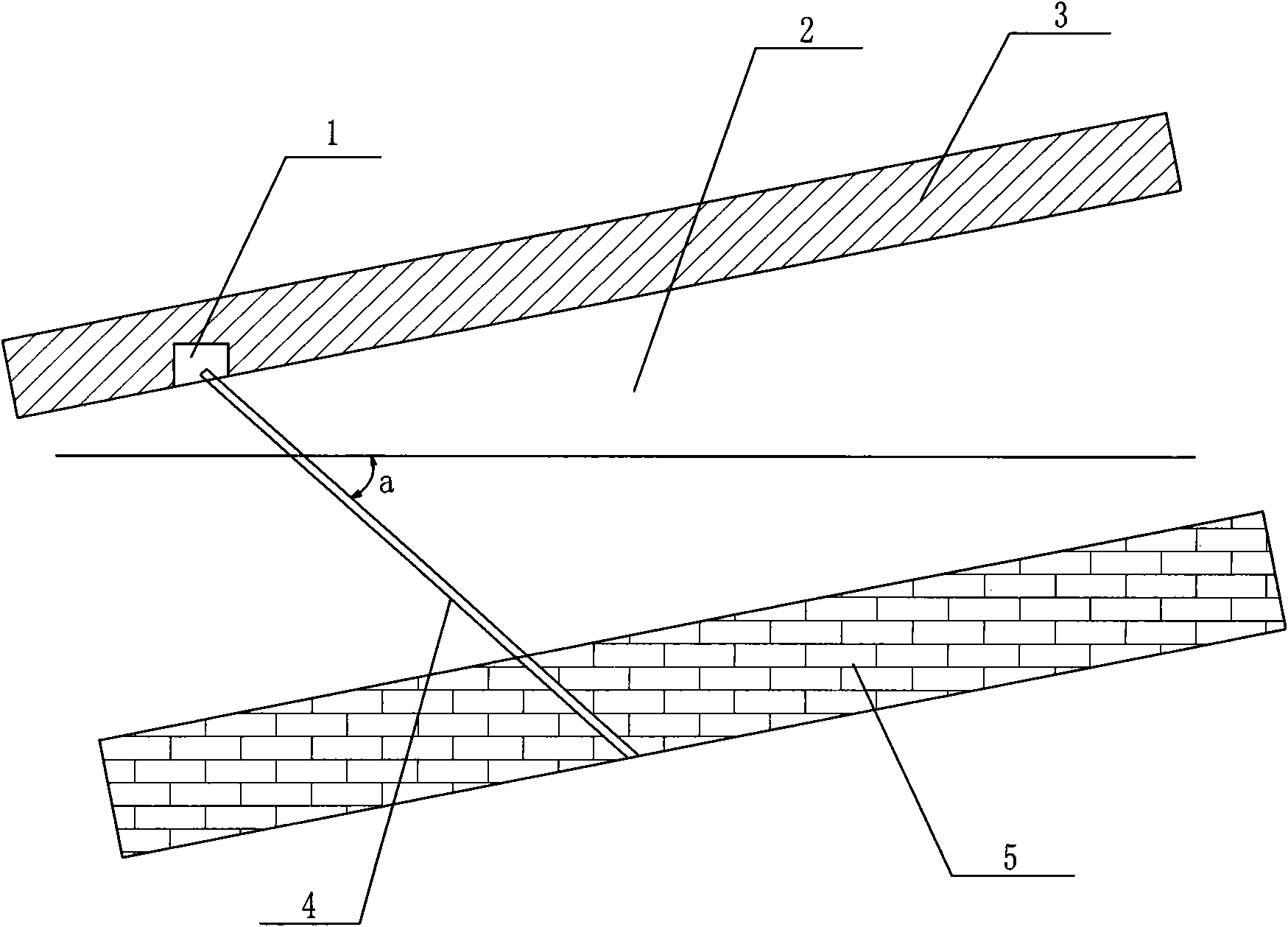

[0014] The structure of the present invention is as figure 1 Shown: including coal seam 3, roadway 1 in the coal seam, coal seam floor L 8 Limestone aquifer 5 and coal seam floor L 8 Aquitard 2 between limestone aquifer and coal seam.

[0015] According to the analysis of the causes of water inrush from the coal seam floor of the mining face, the main cause of the water inrush is: 8 While the limestone was reinforced, the coal seam floor and the L 8 The water-resisting layer between the limestone, due to the large mine pressure, the coal seam floor is severely damaged during the mining of the working face, especially the bottom sill, which will lead to water inrush from the coal seam floor during mining. Therefore, the coal seam floor of the mining face L 8 During limestone grouting reinforcement, the present invention takes the following targeted control grouting measures, and the specific steps are as follows:

[0016] 1) First, use transient electromagnetic to conduct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com