Cyclonic separation filter

A cyclone separation and filter technology, used in suction filters, separation methods, dispersed particle separation, etc., can solve the problems of expensive manufacturing and maintenance costs, complex structures, and large volume of cyclone pipes, reducing motor power, small volume, The effect of a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

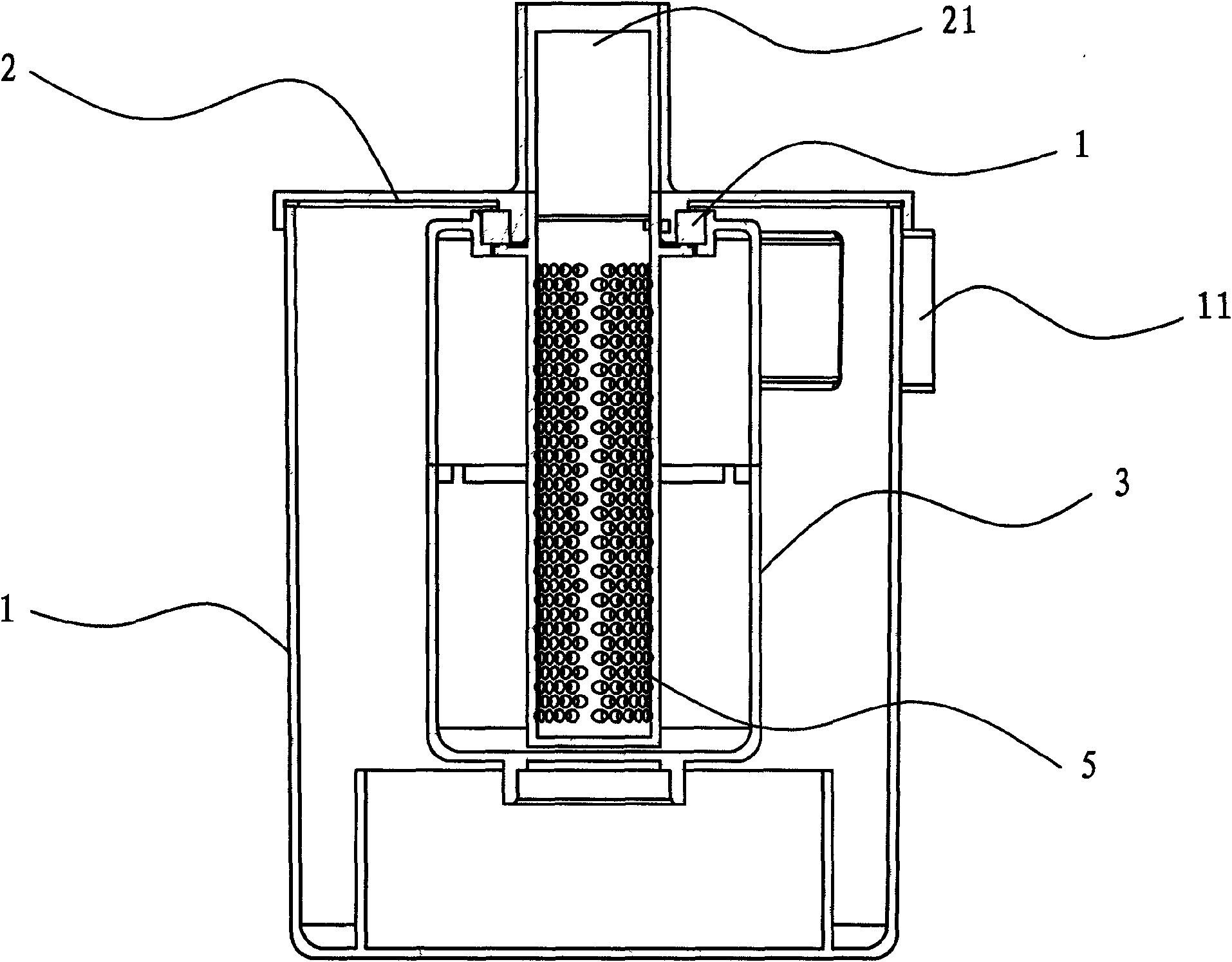

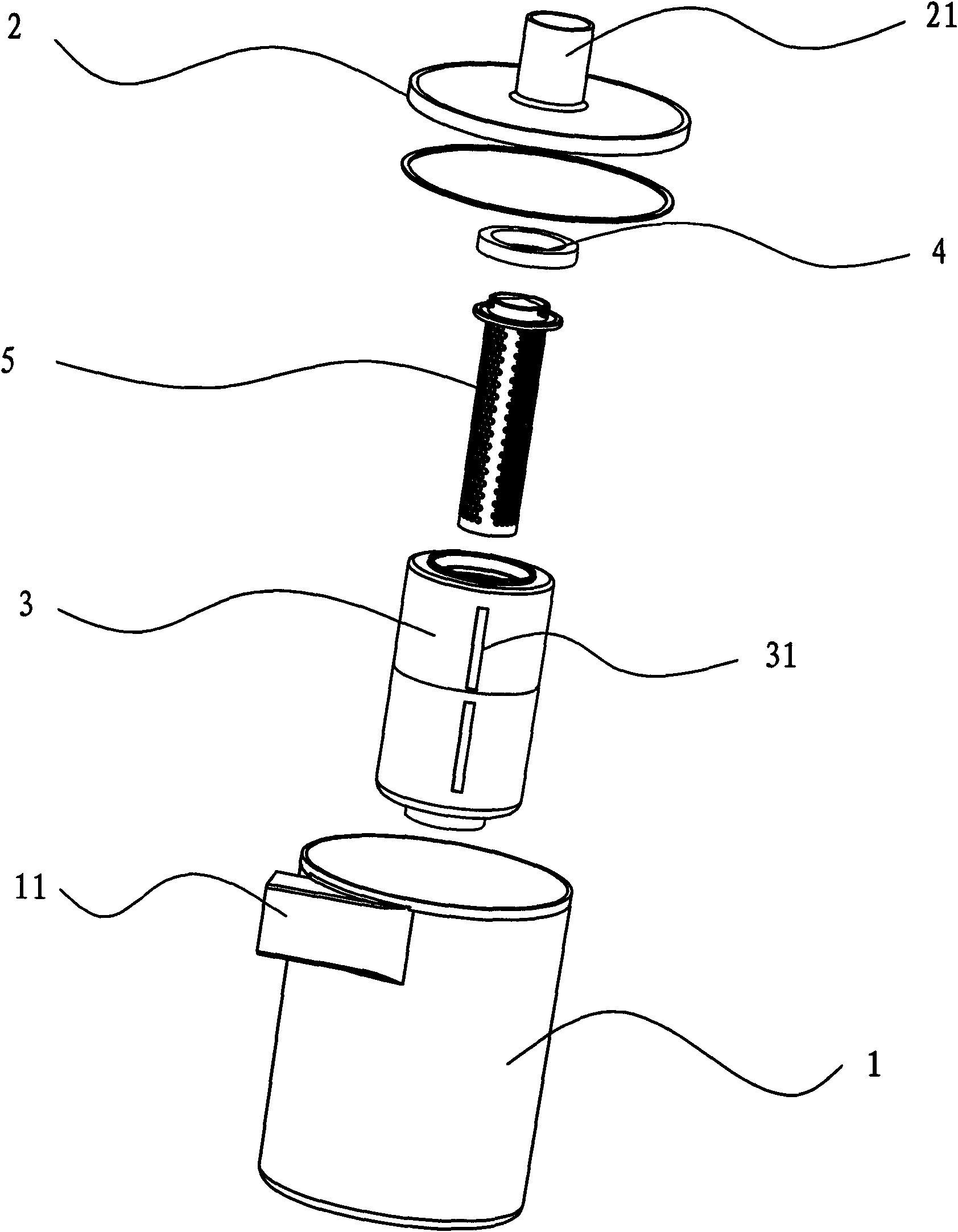

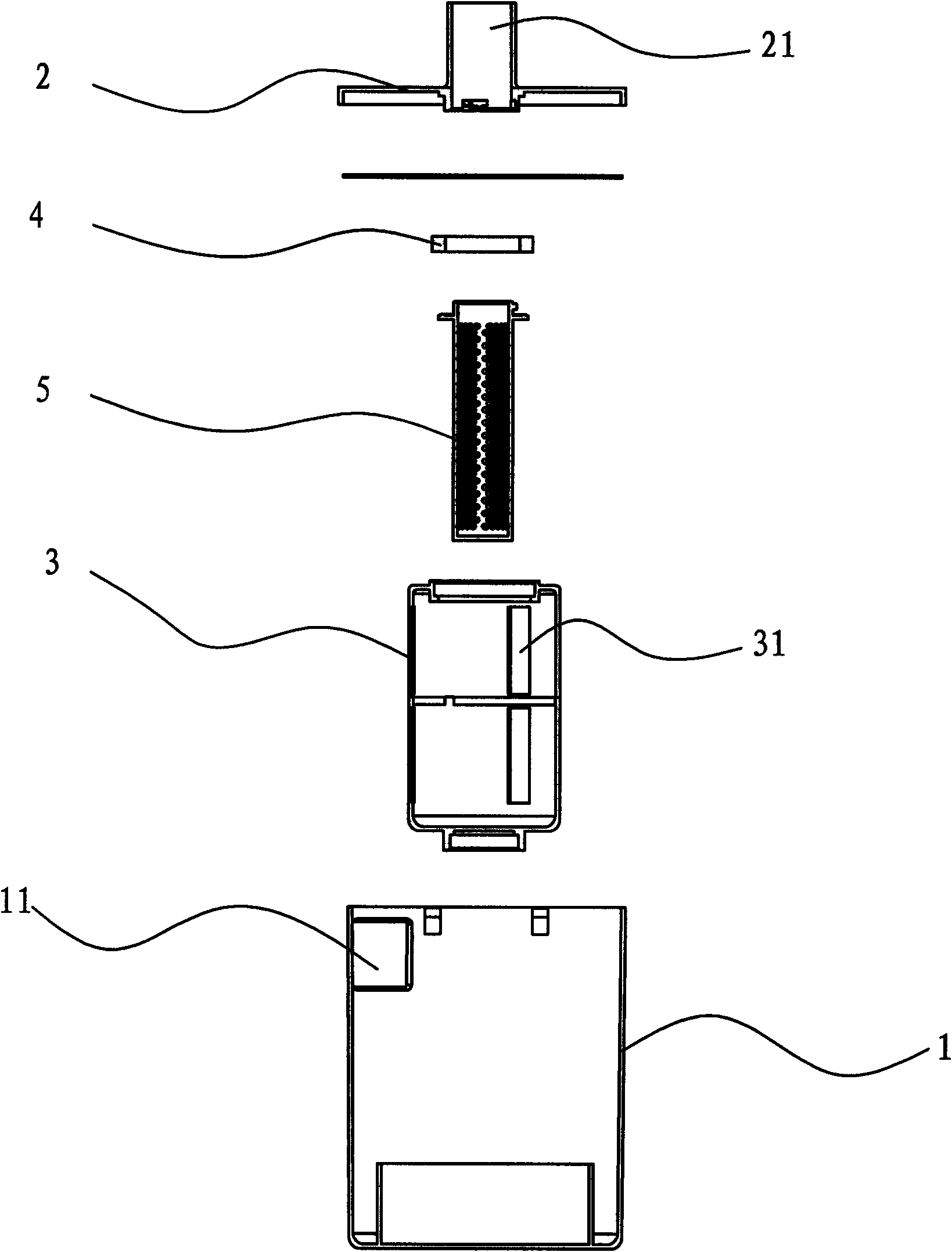

[0019] refer to figure 1 , figure 2 , image 3 , Figure 4 , including a dust box 1, a sealing cover 2, and an air inlet 11 arranged on the dust box 1 and an air outlet 21 arranged on the sealing cover 2, and the internal space formed by the dust box 1 and the sealing cover 2 is vertically fixed with a rotary filter The core 3, the side wall of the rotating filter core 3 is provided with several air inlets 31 which are not parallel to the diameter direction of the cylinder. One end of the rotary filter core 3 is closed, and the other end communicates with the air outlet. A rotary mechanism is arranged between the rotary filter core 3 and the dust box 1 or the sealing cover 2 to limit the axial movement of the rotary filter core 3. The rotary mechanism can be Bearing 4, a bearing 4 is arranged between the rotating filter core 3 and the dust box 1 or the sealing cover 2 . The dust box 1 adopts a transparent material, and when the vacuum cleaner is working, it can be clearly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com