Digital-controlled ball bear inner ring grooved railway multifunctional grinder

A multi-functional technology with inner ring grooves, applied in the direction of grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of large capital occupation, less production batches, unfavorable intensive economic development requirements, etc., and meet the requirements of adapting to Strong performance, saving production cost and production space, flexible and flexible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

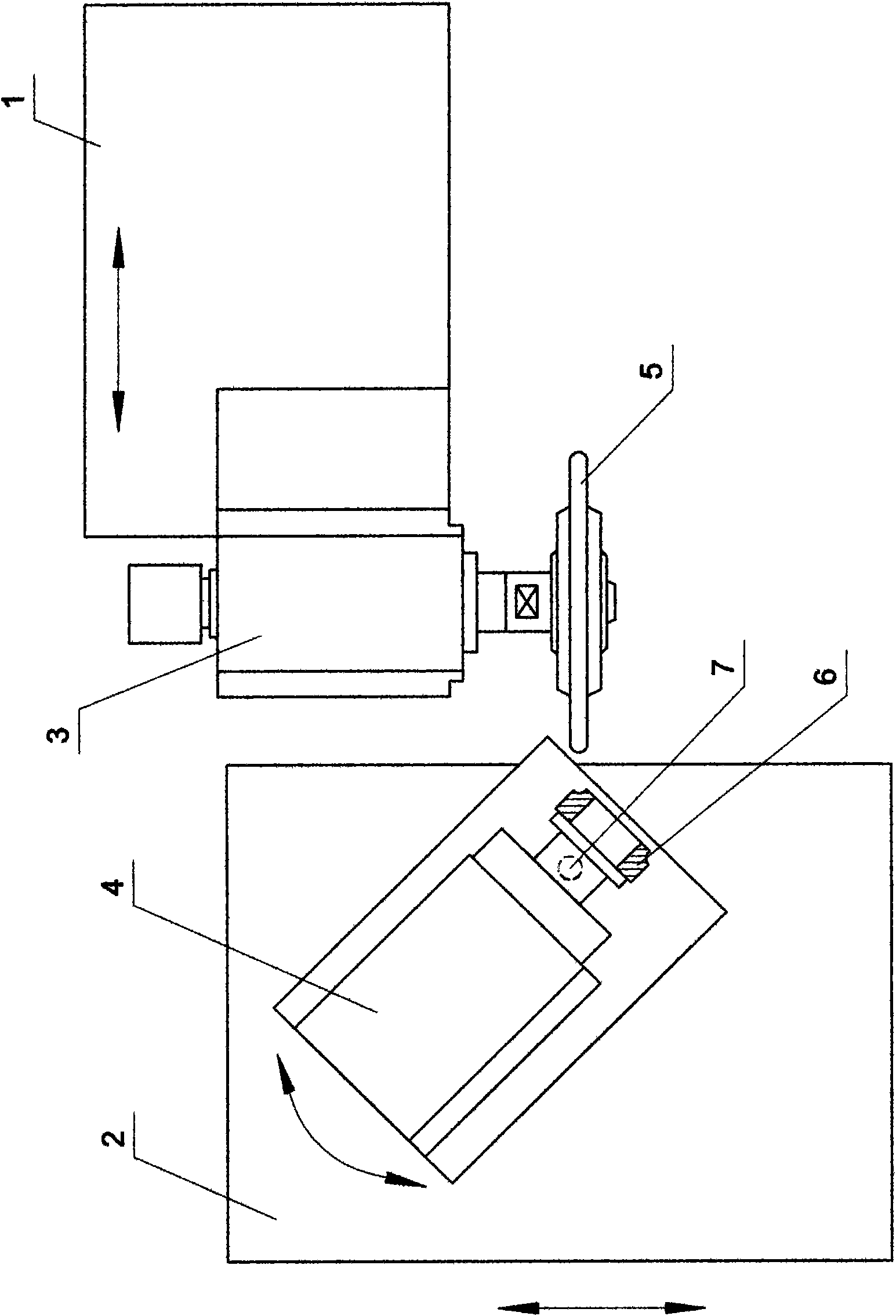

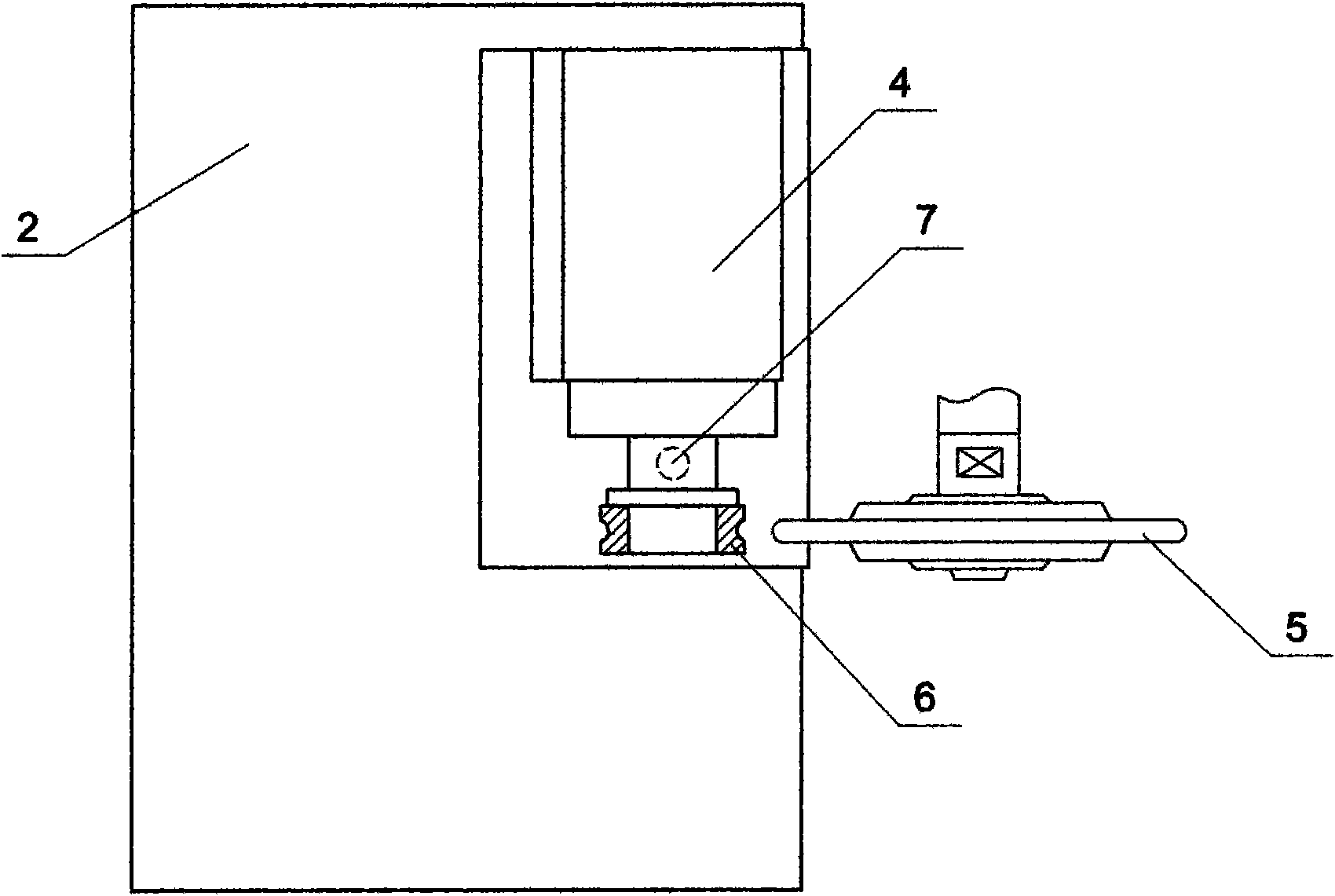

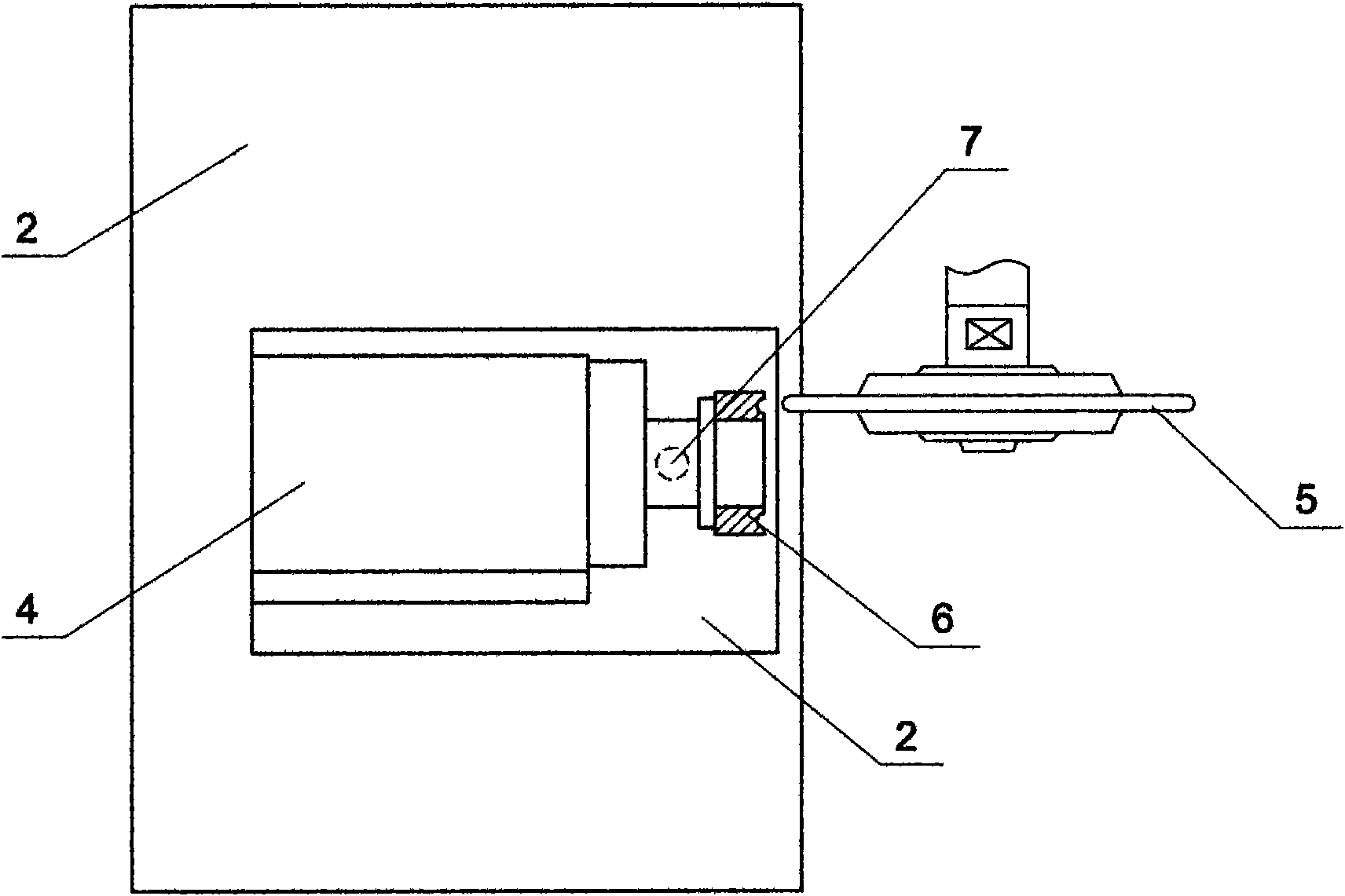

[0029] Example one: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , A CNC ball bearing inner ring channel multifunctional grinder, including a grinding wheel drive mechanism, a workpiece feeding mechanism, wherein the grinding wheel drive mechanism includes a grinding wheel carriage 1, a grinding wheel shaft 3 installed on the grinding wheel carriage 1, and one end of the grinding wheel shaft The grinding wheel 5 and the driving motor at the other end, the workpiece feeding mechanism includes a workpiece carriage 2 and a workpiece box 4 installed on the workpiece carriage.

[0030] A horizontal push-pull mechanism (implemented through a unified numerical control program) is installed in connection with the grinding wheel carriage 1, so that the grinding wheel carriage can drive the grinding wheel 5 to move horizontally. A longitudinal push-pull mechanism (implemented by a unified numerical control program) is installed in connectio...

Embodiment 2

[0037] The second embodiment: the drawings are not drawn, and the meaning is basically the same as that of the first embodiment. The similarities are not repeated. The difference is that a certain precision scale value is set at the relative angular displacement between the workpiece box and the workpiece carriage. So that the angle of rotation can be roughly determined by observation during operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com