Material structure for cover board of automobile storage box

A material structure and storage box technology, applied in vehicle parts, luggage, layered products, etc., can solve the problems of contradicting the development trend of automobiles, high self-weight, non-recyclability, etc., to achieve light weight, improve recyclability, Environmentally friendly and recyclable materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

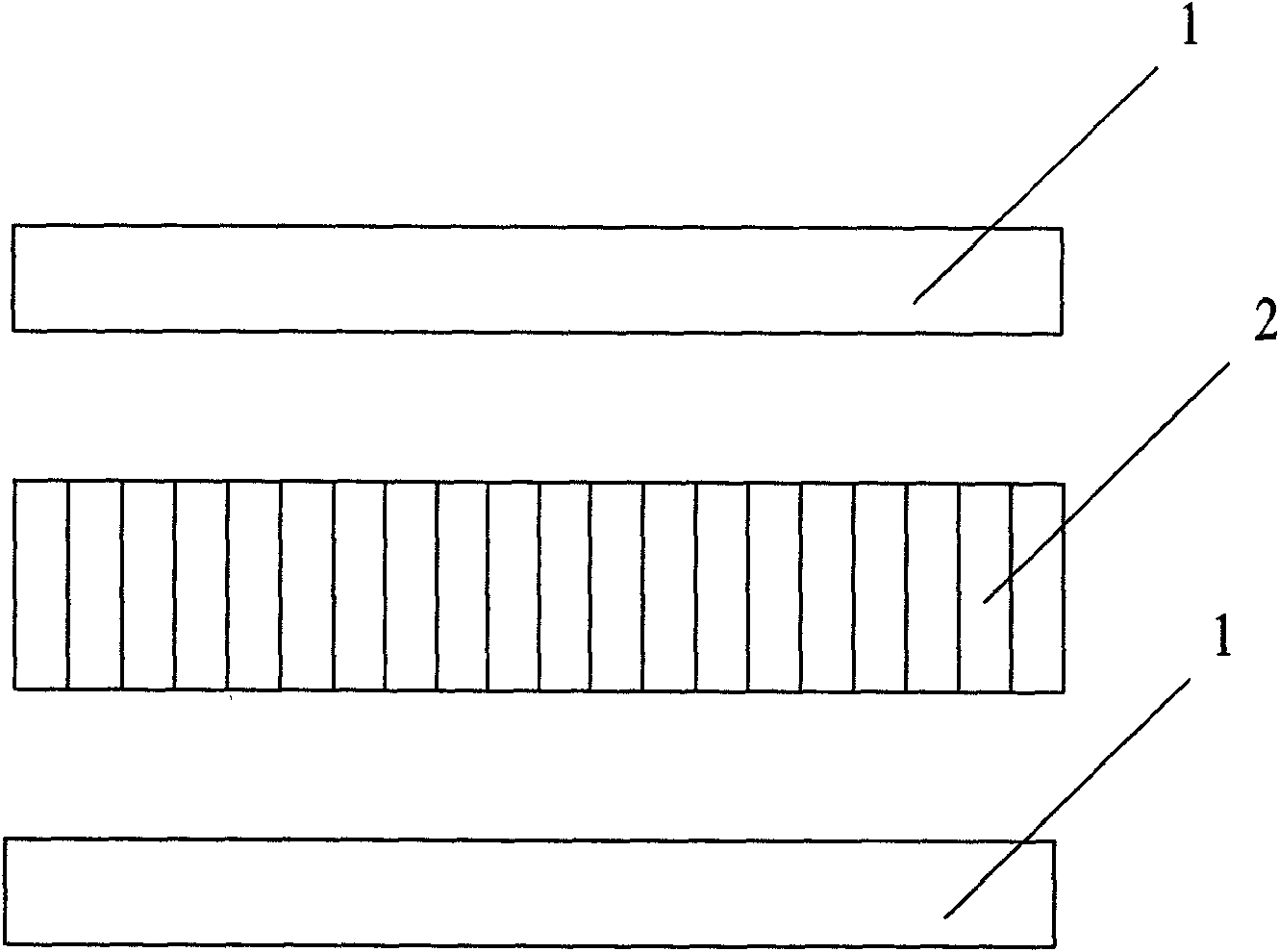

[0016] Adopt Guangzhou Honda 435W rear cushion of the present invention, material composition structure is as follows figure 1 As shown, the material of the upper blanket 1 is PET, the style is needle-punched non-woven fabric, and the weight is 100g / m 2 , the color is black. The material of the base material 2 is PP, and its structure is a honeycomb panel with a weight of 1000g / m 2 , the color is black. The material of the lower blanket 3 is PET, the style is needle-punched non-woven fabric, and the weight is 100g / m 2 , the color is black.

Embodiment 2

[0018] Adopt Dongfeng Honda ZF spare tire cover plate of the present invention, material composition structure is as follows figure 1 As shown, the material of the upper blanket 1 is PET, the style is needle-punched non-woven fabric, and the weight is 200g / m 2 , the color is black. The material of the base material 2 is PP, and its structure is a honeycomb panel with a weight of 2200g / m 2 , the color is black. The material of the lower blanket 3 is PET, the style is needle-punched non-woven fabric, and the weight is 200g / m 2 , the color is black.

Embodiment 3

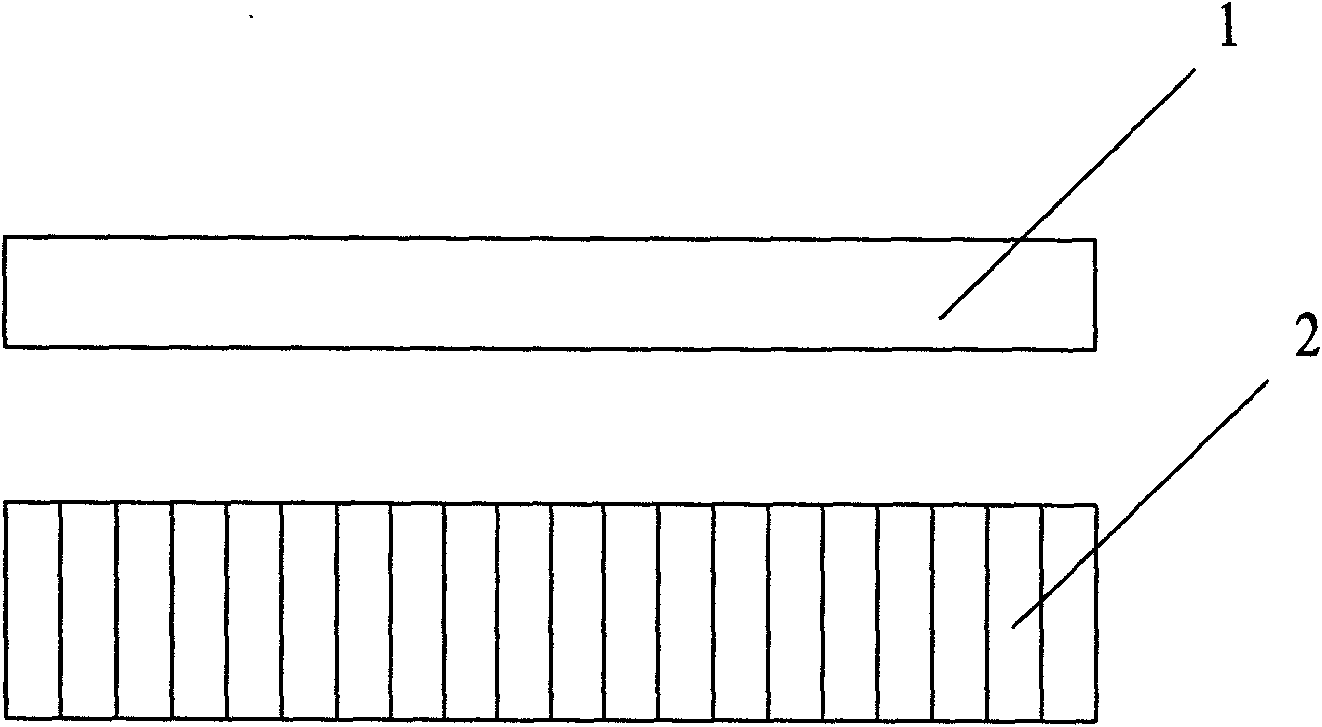

[0020] Adopt Guangzhou Honda L11K trunk trim plate of the present invention, material composition structure is as follows figure 2 As shown, there are only two layers, the material of the upper layer blanket 1 is PET, the style is needle-punched non-woven fabric, and the weight is 150g / m 2 , the color is black. The material of the base material 2 is PP, and its structure is a honeycomb panel with a weight of 500g / m 2 , the color is black.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com