Streamlined high speed pantograph bow

A pantograph and streamlined technology, applied in the pantograph bow head field, can solve the problems of small suspension damping of the bow head body, violent shaking of the bow head body, and poor current receiving state of the pantograph-catenary. The effect of good flow and large suspension damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

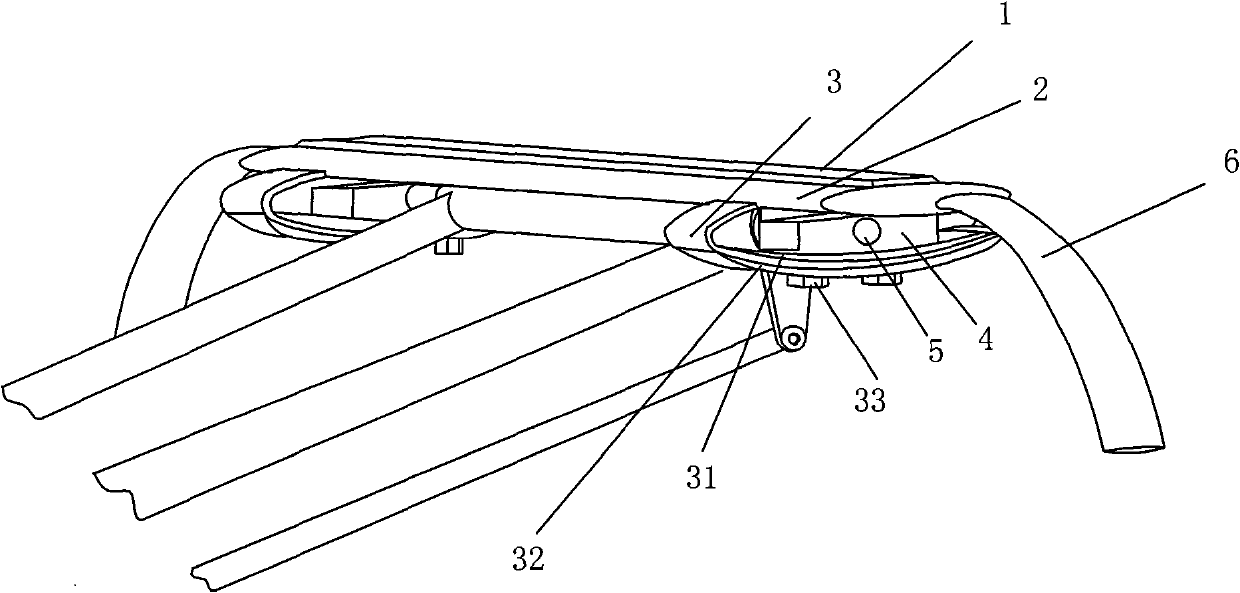

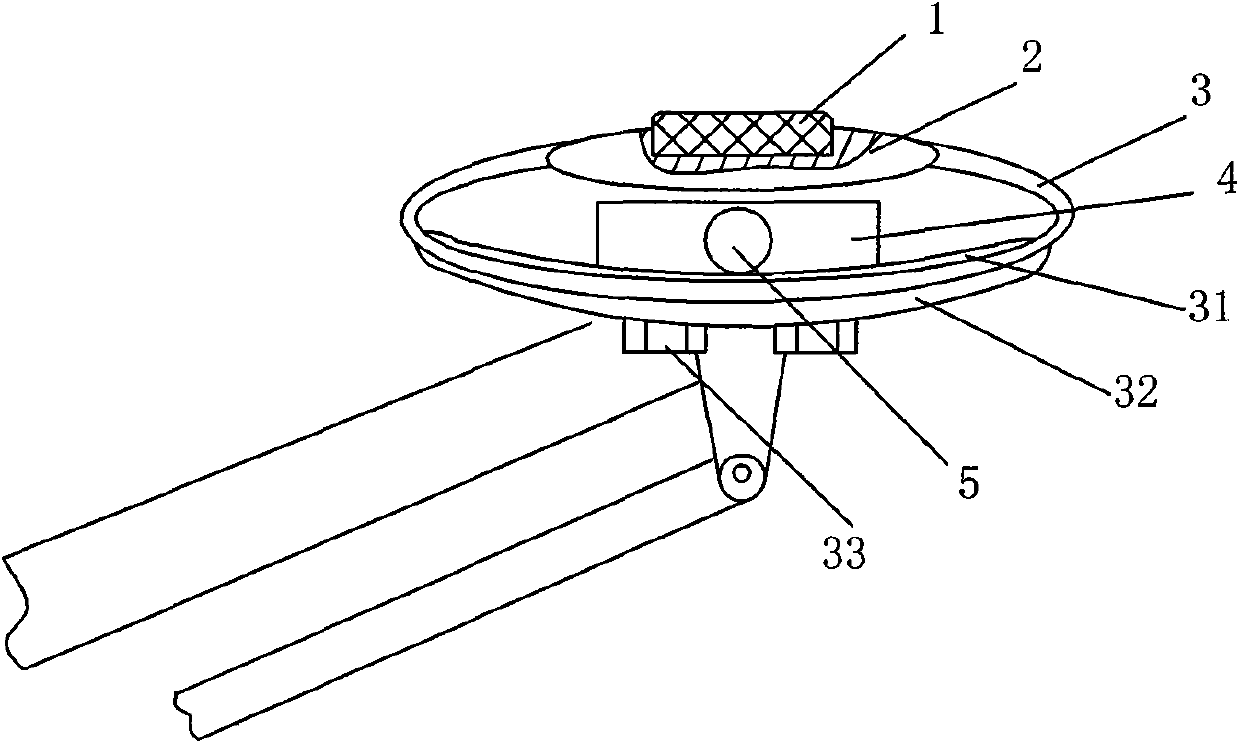

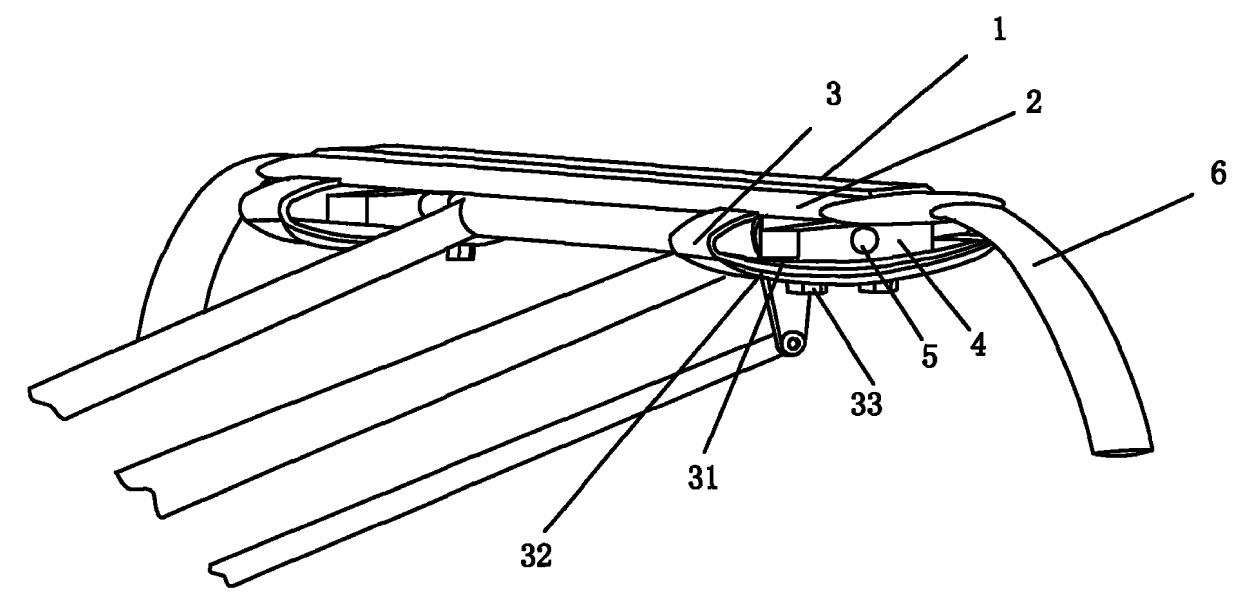

[0017] figure 1 , 2 It is shown that a specific embodiment of the present invention is: a streamlined high-speed pantograph bow head, including a bow head body 1 , a carbon slide plate 2 and a bow angle 6 . The cross-sectional shape of the bow body 1 is streamlined, and the upper surface of the bow body 1 is provided with a strip-shaped carbon slide groove, and a carbon slide plate 2 is embedded in the carbon slide groove, and the left and right sides of the bow body 1 are respectively A streamlined leaf spring 3 is connected, and the leaf spring 3 is located below the bow head body 1 . The concave surface of the leaf spring 3 is provided with a bow head support block 4 , and the bow head support block 4 is hinged with the pantograph frame 5 . The streamline shape of the section of the bow body 1 is drop-shaped or elliptical.

[0018] The concave surface of the leaf spring 3 is provided with an inner auxiliary leaf spring 31, and the convex surface is provided with an outer ...

Embodiment 2

[0020] The structure of this example is basically the same as that of Embodiment 1, the only difference is that both sides of the leaf spring are closed with leaf spring covers; after both sides are closed with leaf spring covers, the closed cavity formed is filled with soft rubber and plastic materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com